Understanding Professional Wire Mesh Manufacturing

Wire mesh manufacturers are a key link in global supply chains serving construction, agriculture, industry, and security projects. For B2B buyers, wire mesh is not just a standard product, but a functional material that must meet specific strength, durability, and dimensional requirements. Choosing the right production partner directly affects project safety, service life, and overall procurement cost.

Unlike trading companies, professional manufacturing facilities control every stage of production, ensuring consistent quality across large and repeat orders. This production stability is especially important for wholesalers, distributors, and engineering contractors.

Product Categories Supplied by Wire Mesh Factories

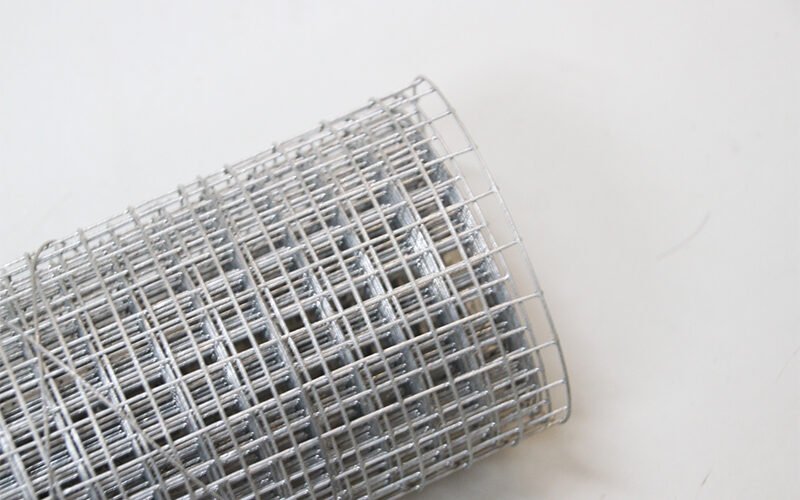

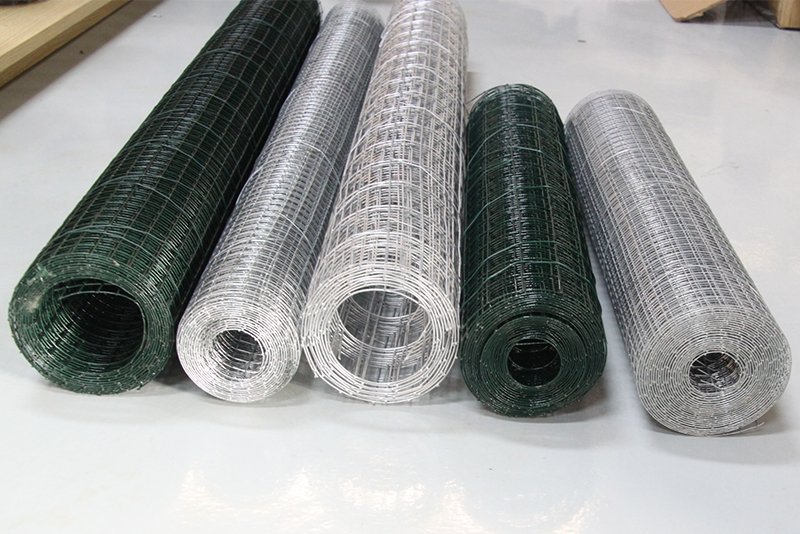

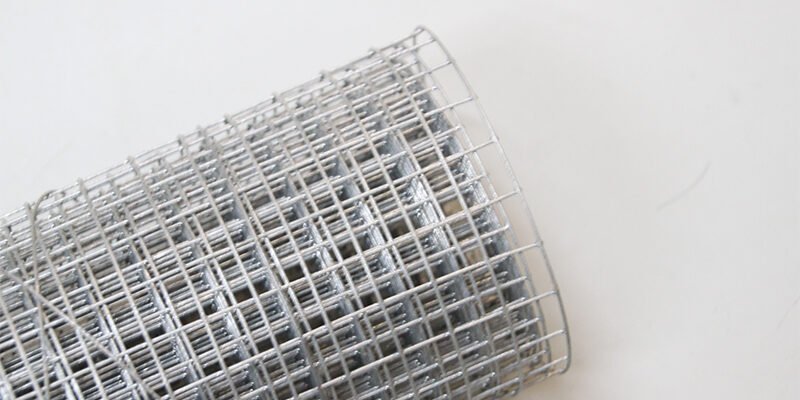

A qualified wire mesh factory usually offers a broad product range to support different applications. Welded wire mesh and welded wire mesh fence systems are commonly used in concrete reinforcement, warehouse partitions, and perimeter fencing. Woven mesh products are widely applied in industrial screening, filtration, and protective barriers. Hexagonal wire mesh is frequently used in poultry cages, livestock enclosures, and agricultural fencing due to its flexibility and shock resistance.

For security applications, barbed wire and razor wire are often integrated into fencing systems to enhance deterrence. These products are often combined with iron wire, wire rope, and iron nail solutions to form complete installation systems.

Material Options and Surface Treatments

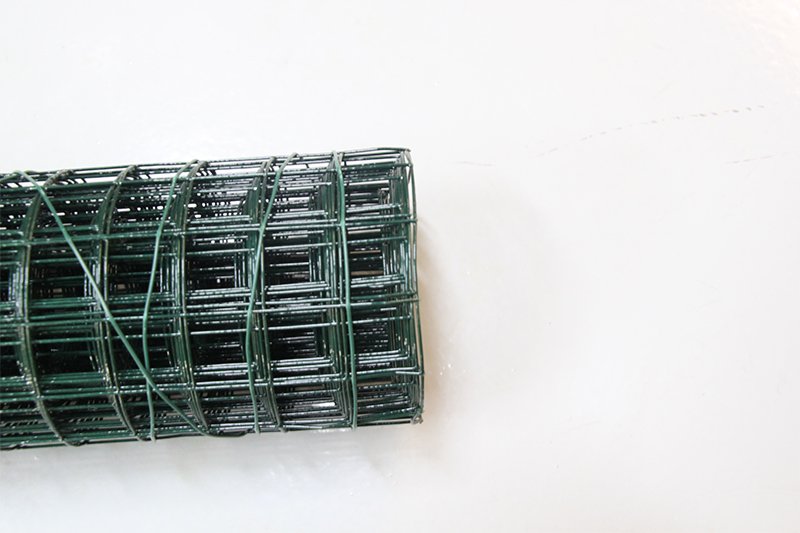

Material selection plays a major role in wire mesh performance. Galvanized steel wire mesh provides strong corrosion resistance for outdoor environments and long-term use. PVC coated wire offers additional protection while improving appearance and lifespan in humid or coastal areas. Stainless steel woven wire mesh is preferred in industrial and food-related applications where chemical resistance and hygiene standards are required.

Each material and surface treatment option impacts durability, maintenance cost, and compliance with local standards, making proper selection essential for B2B buyers.

Manufacturing Technology and Production Capability

Advanced production technology is a defining feature of reliable manufacturers. Automatic welding equipment ensures uniform weld points and consistent panel strength. Precision weaving machines control mesh opening accuracy, which is critical for filtration and screening uses. Galvanizing and coating lines ensure stable zinc layers and smooth finishes, reducing the risk of rust and early failure.

Factories with modern equipment and experienced technical teams are better positioned to handle large-volume orders and customized specifications.

Customization and OEM Support for Bulk Buyers

One of the main advantages of sourcing directly from factories is customization capability. Buyers can request specific wire diameters, mesh openings, roll lengths, panel sizes, and packaging methods. OEM services, private labeling, and customized branding help distributors and wholesalers differentiate themselves in local markets.

This flexibility allows wire mesh products to be adapted to regional standards, project requirements, and customer preferences.

Quality Control and Inspection Standards

Reliable wire mesh suppliers implement strict quality control procedures throughout the production process. These include raw material inspection, wire diameter tolerance checks, weld strength testing, surface coating measurement, and final packaging verification.

For export orders, professional factories can support sample approval and third-party inspection, helping international buyers reduce procurement risk and maintain consistent quality.

Export Experience and Logistics Support

Export capability is another critical factor when selecting a manufacturing partner. Experienced suppliers understand international packing standards, container loading optimization, and export documentation requirements. Proper bundling, palletizing, and moisture protection help minimize damage during long-distance transportation.

Flexible trade terms such as FOB and CIF allow buyers to manage logistics according to their own supply chain strategies.

Choosing the Right Manufacturing Partner

When evaluating wire mesh manufacturers, B2B buyers should look beyond pricing alone. Production capacity, technical support, communication efficiency, customization ability, and after-sales service all contribute to successful long-term cooperation.

A reliable factory acts as a solution-oriented partner, helping customers select suitable combinations of welded wire mesh, woven mesh, fencing systems, and related steel products for different applications.

Factory Introduction – Trusted Welded Wire Mesh Supplier from China

TianSheng Wire Mesh is a professional manufacturer specializing in metal wire and wire mesh products for global B2B markets. The factory supplies welded wire mesh, hexagonal wire mesh, woven mesh, welded wire mesh fence systems, barbed wire, razor wire, galvanized iron wire, PVC coated wire, wire rope, and iron nail products for construction, agriculture, industrial, and security applications.

Equipped with modern automatic production lines and supported by an experienced technical team, TianSheng Wire Mesh maintains strict control over wire diameter tolerance, welding strength, mesh accuracy, and surface treatment quality. Both standard and customized specifications are available to meet different regional and project requirements. OEM services and private labeling are supported for wholesalers and distributors.

Quality control is applied from raw material selection to final packaging. Export-standard packing methods are designed to protect products during transportation and improve container loading efficiency. With stable production capacity, competitive factory pricing, and professional export support, TianSheng Wire Mesh has built long-term cooperation with customers across Africa, the Middle East, South America, and Southeast Asia.

Post a Comment