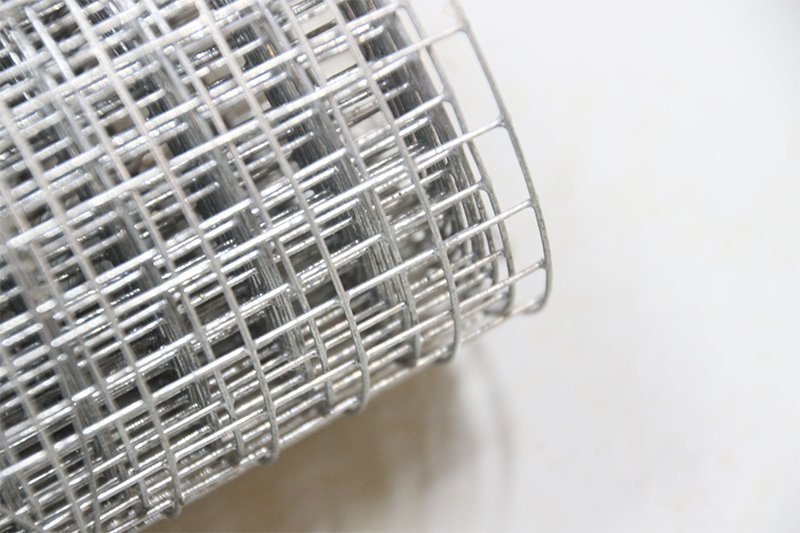

Square Wire Fence for Commercial Supply and Bulk Projects

Square wire fence is widely used in agricultural, industrial, and infrastructure projects where strength, consistency, and cost control are critical. For wholesalers, distributors, and project contractors, square-pattern wire panels offer a reliable fencing material that can be easily standardized, customized, and supplied in large volumes.

Rather than focusing on decorative fencing, B2B buyers prioritize performance, logistics efficiency, and long-term cooperation with manufacturers.

Why Square-Pattern Wire Panels Are Preferred in B2B Markets

In commercial and project-based applications, fencing materials must perform under pressure. Square mesh wire fencing meets these expectations by offering a balanced structure that distributes force evenly across the panel.

Key reasons professional buyers choose this structure include:

-

Uniform mesh for predictable strength

-

Strong welded intersections

-

Easy integration with posts and frames

-

Compatibility with multiple installation methods

This makes welded square panels suitable for both permanent and semi-permanent fencing systems.

Typical Applications Across Industries

Steel wire mesh panels with square openings are commonly used in:

-

Livestock and farm enclosures

-

Warehouse and factory perimeters

-

Utility and infrastructure protection

-

Residential developments supplied by contractors

Because the same panel structure can be used across different sectors, distributors benefit from broader market coverage and faster inventory turnover.

Material and Production Considerations

From a manufacturer’s perspective, square-opening wire panels are efficient to produce and control. Automated welding lines ensure accuracy and consistency, which is essential for bulk supply.

Professional buyers usually evaluate:

-

Wire material: low-carbon steel for strength and flexibility

-

Wire diameter: matched to security or livestock needs

-

Mesh opening size: optimized for safety and visibility

-

Surface treatment: hot-dip galvanizing or PVC coating for corrosion resistance

Factories with mature production systems are better positioned to support long-term B2B partnerships.

Advantages for Wholesale and Project Buyers

Compared with chain link or temporary fencing, square mesh panel systems provide several commercial advantages:

-

Flat-panel structure reduces transport volume

-

Easier stacking and container loading

-

Lower installation labor cost

-

Reduced maintenance over time

For importers and distributors, these factors directly affect landed cost and resale margins.

Customization and OEM Supply

Manufacturers supplying welded square wire panels often provide OEM services, including:

-

Custom panel dimensions

-

Region-specific mesh spacing

-

Branding and private-label packaging

-

Project-based specification support

This flexibility allows wholesalers to tailor products to local regulations and customer expectations without redesigning the entire fencing system.

Export and Logistics Efficiency

Square mesh steel panels are export-friendly by design. Bundled or palletized packing minimizes damage during transport and improves container utilization.

For international buyers, this means:

-

More predictable shipping costs

-

Reduced breakage risk

-

Faster unloading and distribution

These logistical efficiencies are a major reason why distributors prefer welded panel fencing products for global sourcing.

Choosing the Right Manufacturing Partner

For B2B buyers, the product itself is only part of the equation. A reliable manufacturer should offer:

-

Stable production capacity

-

Consistent quality control

-

Clear communication on lead times

-

Experience with bulk and project orders

Such partnerships help wholesalers and contractors maintain stable supply chains and protect their reputation in local markets.

Conclusion

For distributors and project buyers seeking a durable and scalable fencing solution, square wire fence remains a practical choice when sourced directly from an experienced manufacturer. With standardized production, flexible specifications, and efficient logistics, this fencing format continues to meet the demands of modern B2B markets.

👉 If you are sourcing welded square mesh panels for wholesale or project use, contact us to discuss specifications, capacity, and factory-direct pricing.

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment