Screen Wire Mesh: A Practical Solution for Filtration, Protection, and Ventilation

Screen wire mesh is one of the most versatile metal mesh products used across industrial, agricultural, and residential applications. Manufactured from steel wire through precise weaving or welding processes, it provides controlled openings, reliable strength, and long-term performance. Whether used for screening, ventilation, or protective barriers, this type of mesh plays a critical role in improving safety, efficiency, and durability.

What Is Screen Wire Mesh?

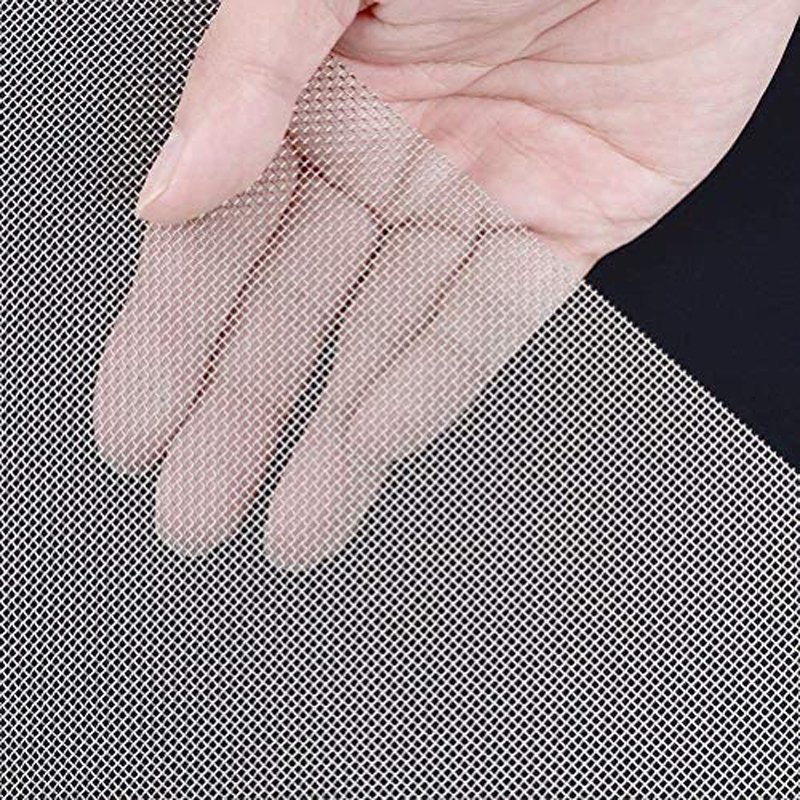

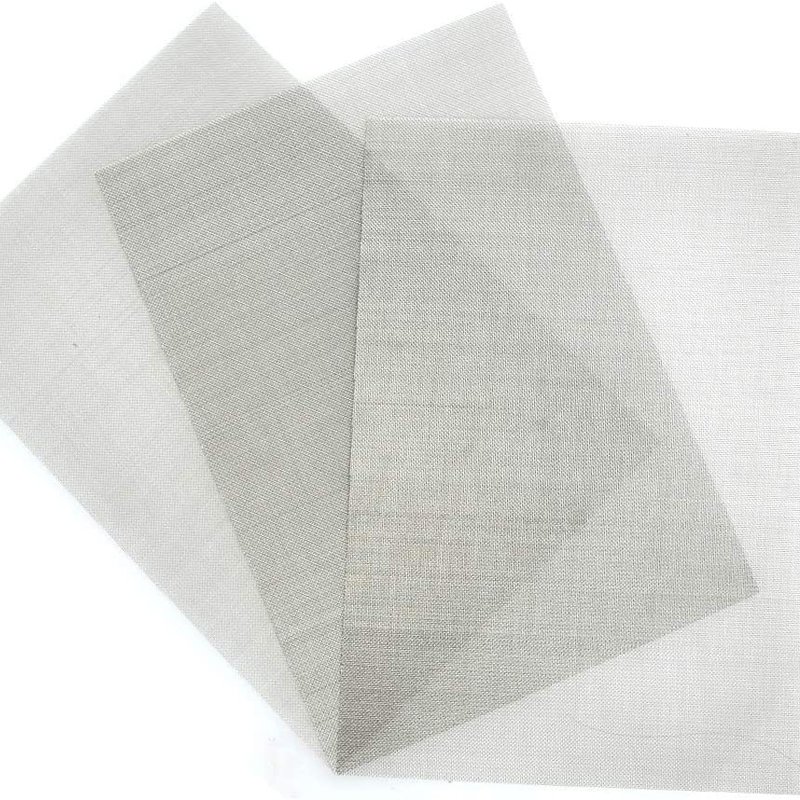

Screen wire mesh refers to metal mesh designed primarily for screening, filtering, or protective purposes. It is commonly produced using stainless steel, galvanized steel, or low-carbon steel wire. Depending on application needs, the mesh can be woven for flexibility or welded for rigidity.

The key feature of screen mesh lies in its uniform openings, which allow airflow, light, or liquid to pass through while blocking unwanted particles, insects, debris, or animals. This balance makes it suitable for both functional and visual applications.

Key Advantages and Performance Features

One of the main benefits of screen wire mesh is its material durability. Galvanized and stainless steel options provide strong resistance to rust, moisture, and environmental exposure, ensuring long service life even in outdoor or industrial environments.

Another important advantage is precision manufacturing. Controlled wire diameter and mesh spacing ensure consistent performance, especially for filtration and screening tasks where accuracy matters. Smooth wire surfaces and clean intersections also improve safety during handling and installation.

In addition, screen mesh offers design flexibility. It can be cut, shaped, or framed to suit different installation conditions, making it ideal for custom projects and large-scale applications alike.

Common Applications Across Industries

Screen wire mesh is widely used in a variety of fields:

-

Industrial filtration and screening, such as sieving, separation, and ventilation systems

-

Agricultural uses, including pest control, grain screening, and animal enclosures

-

Construction and infrastructure, for window screens, protective guards, and partitions

-

Residential and commercial spaces, such as insect screens, garden protection, and safety covers

Different mesh sizes and wire thicknesses allow users to select the right balance between airflow, strength, and protection.

Woven vs Welded Screen Mesh

Choosing between woven and welded structures depends on the application.

Woven screen mesh is created by interlacing wires, offering better flexibility and shock absorption. It is ideal for filtration, vibration screening, and applications requiring fine openings.

Welded screen mesh features rigid intersections formed by welding, providing higher structural stability. It is commonly used where fixed shape and strength are required, such as fencing, guards, and cages.

Understanding these structural differences helps ensure optimal performance and cost efficiency.

Buying Guide: How to Choose the Right Screen Wire Mesh

When selecting screen wire mesh, consider the following factors:

-

Material – Choose stainless steel for corrosion resistance, galvanized steel for cost efficiency, or carbon steel for indoor use.

-

Mesh size and wire diameter – Smaller openings offer better screening, while thicker wires provide higher strength.

-

Application environment – Outdoor or humid conditions require protective coatings or stainless steel.

-

Form – Rolls are suitable for large areas, while sheets or panels fit framed installations.

Working with a factory-direct supplier ensures better quality control, customization options, and competitive pricing.

Conclusion

Screen wire mesh remains an essential metal mesh solution due to its versatility, durability, and precise performance. From industrial filtration to everyday protection, its adaptability makes it a reliable choice for both functional and structural needs. Selecting the right material, structure, and specification ensures long-term value and consistent results.

📩 For specifications, bulk orders, or customization support, contact us directly via WhatsApp: +86 18830227875

Request a Quote or Custom Solution

If you are sourcing fencing for agricultural, commercial, or infrastructure projects, our team can help you select the right specification and provide fast technical support.

📲 Contact us on WhatsApp: +86 18830227875

Get factory pricing, export-ready products, and reliable delivery from a trusted wire mesh supplier.

Our Factory Advantages

With years of experience in wire and mesh manufacturing, TS Wire Mesh is a professional factory specializing in metal wire, wire mesh fencing, and custom steel products for global markets. We focus on stable quality, factory-direct pricing, and long-term cooperation with wholesalers, distributors, and project buyers worldwide.

1. Factory-Direct Manufacturing, Competitive Pricing

As a source manufacturer, we control the entire production process—from raw material selection to wire drawing, welding, weaving, surface treatment, and packing. This direct factory operation eliminates unnecessary middle costs, allowing us to offer competitive ex-factory prices while maintaining consistent quality. OEM and bulk orders are always welcome.

2. Strict Raw Material & Quality Control

We use carefully selected low-carbon steel wire, high-carbon steel wire, galvanized steel wire, and stainless steel wire sourced from qualified steel mills. Every production stage follows internal quality inspection standards, including wire diameter tolerance, zinc coating thickness, weld strength, and tensile performance. Export-grade quality control ensures stable performance in different climates and applications.

3. Wide Product Range, One-Stop Supply

Our factory produces a complete range of wire and mesh products, including:

-

Hexagonal wire mesh (chicken wire)

-

Field fence & livestock fencing

-

Galvanized / PVC coated iron wire

-

Steel cable wire rope

This one-stop supply capability helps buyers reduce sourcing time, logistics costs, and communication risks.

4. Customization & OEM Capability

We support custom specifications such as wire diameter, mesh opening, panel size, roll length, surface finish, and packaging design. Our technical team works closely with customers to meet market standards in North America, Europe, Africa, and the Middle East. Private label and OEM packaging are fully supported.

5. Export Experience & Reliable Delivery

With rich export experience, we are familiar with international trade processes, packaging requirements, and container loading solutions. Stable production capacity and efficient scheduling allow us to ensure on-time delivery for both small trial orders and large-volume shipments.

6. Professional Service & Long-Term Partnership

Our team understands B2B buyers’ real needs—quality stability, clear communication, and after-sales responsibility. We aim to build long-term partnerships, not just one-time transactions, by providing honest quotations, fast responses, and continuous support.

Post a Comment