Razor Wire vs Barbed Wire: Key Differences, Uses, and Cost Comparison

When choosing perimeter security solutions, razor wire vs barbed wire is a common comparison for contractors, wholesalers, and project buyers. While both are designed to deter intrusion, their structure, security level, cost, and application scenarios differ significantly. Understanding these differences helps buyers select the most cost-effective and suitable fencing material for their projects.

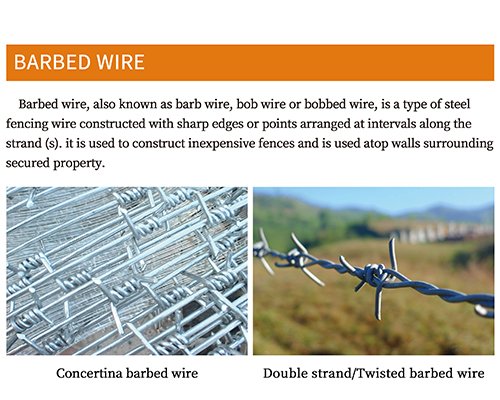

1. What Is Barbed Wire?

Barbed wire consists of twisted steel strands with evenly spaced barbs along the length. It is typically manufactured from galvanized steel wire or PVC coated wire to improve corrosion resistance.

Key Features of Barbed Wire

-

Simple twisted-wire structure

-

Moderate deterrent effect

-

Lightweight and flexible

-

Easy to install and transport

-

Low material and installation cost

Common Applications

Barbed wire is widely used for:

-

Agricultural fencing (farms, ranches, livestock enclosures)

-

Property boundary marking

-

Temporary fencing solutions

-

Rural and low-risk perimeter protection

Barbed wire focuses more on psychological deterrence rather than physical injury prevention, making it suitable for large-area coverage at minimal cost.

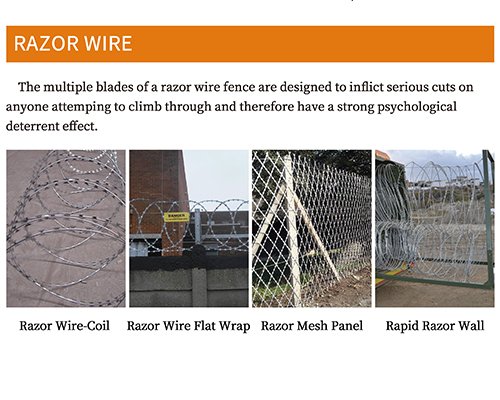

2. What Is Razor Wire?

Razor wire is manufactured using a high-tensile steel core wire with sharp steel blades punched from a steel strip. These blades are much sharper and closer together than traditional barbs.

Key Features of Razor Wire

-

Extremely sharp blade edges

-

High deterrence and physical protection

-

Difficult to cut or climb

-

Strong visual warning effect

-

Available in coils or flat wraps

Common Applications

Razor wire is commonly used in:

-

Military and defense facilities

-

Prisons and detention centers

-

Airports and border fencing

-

Industrial zones and high-security sites

-

Power plants and critical infrastructure

Razor wire is designed for maximum security, where unauthorized access must be prevented at all costs.

When comparing **razor wire vs barbed wire**, the right choice depends on the level of security required and the environment where the fence will be installed. Razor-style barriers deliver superior resistance, while traditional barbed wire remains a cost-efficient solution that balances protection and budget.

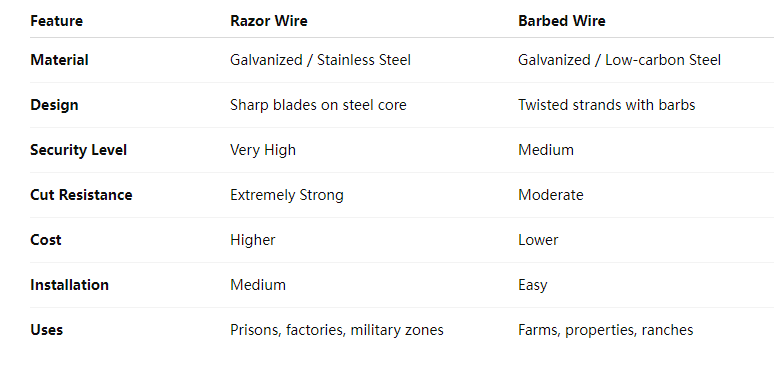

Comparison Table

4. Cost Comparison: Which Is More Economical?

From a price perspective, barbed wire is significantly cheaper per roll and requires less safety equipment during installation. This makes it ideal for large-scale fencing where budget control is critical.

Razor wire, while more expensive, offers higher security per meter. For high-risk areas, the cost of razor wire is justified by reduced security breaches and lower need for additional fencing layers.

B2B buyers often select:

-

Barbed wire for long-distance perimeter fencing

-

Razor wire for topping fences or securing critical access points

5. Installation and Safety Considerations

Barbed wire can be installed with basic tools and minimal protective equipment. Razor wire installation, however, requires:

-

Protective gloves and clothing

-

Trained installation personnel

-

Secure mounting structures

Improper handling of razor wire can result in serious injury, which is why professional installation is recommended.

6. Which One Should You Choose?

Choose barbed wire if you need:

-

Cost-effective fencing

-

Agricultural or rural applications

-

Large-area coverage with basic security needs

Choose razor wire if your project requires:

-

Maximum intrusion prevention

-

High-security environments

-

Long-term protection with minimal breach risk

In many projects, combining both materials delivers the best balance between cost control and security performance.

7. Wholesale Supply, Custom Manufacturing, and Project Support

For large-scale fencing and security projects, sourcing reliable materials from a qualified manufacturer is just as important as selecting the right product. As a factory-direct supplier, we provide stable wholesale supply of both barbed wire and razor wire for distributors, contractors, and government projects worldwide.

Flexible Manufacturing Capabilities

Our production lines support a wide range of technical customizations to meet different project standards and site conditions, including:

-

Wire diameter adjustments for strength and flexibility control

-

Blade or barb spacing customization based on security level requirements

-

Hot-dipped galvanized, electro-galvanized, and PVC coated finishes

-

Standard and reinforced blade profiles for razor wire

-

Coil diameter, loop count, and packing format customization

All materials are produced under strict quality control procedures to ensure consistent tensile strength, coating thickness, and long-term corrosion resistance.

Bulk Orders and Export Packaging

For wholesale and export orders, we offer:

-

Project-based pricing for container loads and mixed shipments

-

Secure packing suitable for long-distance sea transport

-

Labeling, palletizing, and OEM branding upon request

-

HS code and export documentation support

This ensures smooth customs clearance and reduced handling risks at destination ports.

Technical and Application Support

Our team assists buyers not only with product supply, but also with technical selection and usage guidance, including:

-

Product comparison based on site risk level

-

Quantity estimation for perimeter length and fence layout

-

Installation recommendations and safety guidelines

-

Cost-performance analysis for budget optimization

Reliable Long-Term Partnership

We focus on building long-term cooperation with B2B clients by offering:

-

Stable lead times and scalable production capacity

-

Consistent quality across repeat orders

-

Fast response for inquiries and project updates

📲 Contact us via WhatsApp +86 18830227875 to discuss specifications, drawings, and wholesale pricing. Factory-direct support is available for your next security fencing project.

Related Products You May Need

1. Galvanized Barbed Wire Fence

Widely used together with razor wire for layered perimeter security, galvanized barbed wire provides strong deterrence at a lower cost. Suitable for farms, industrial zones, and boundary fencing projects.

Material: High tensile galvanized steel

Application: Agricultural fencing, security perimeters, access control

2. Welded Wire Mesh Fence Panels

Often installed below razor wire or barbed wire coils, welded wire mesh fence panels offer structural support and clear boundary definition. Ideal for prisons, factories, warehouses, and infrastructure projects.

Material: Low carbon steel wire / galvanized steel

Application: Security fencing, industrial enclosures, site protection

3. Chain Link Wire Mesh Fence

Chain link fencing is a common base fence system combined with razor wire on top for enhanced security. Its flexibility and cost efficiency make it popular for large-scale fencing projects.

Material: Galvanized or PVC coated steel wire

Application: Airports, highways, construction sites, sports facilities

Post a Comment