1. Product Overview

Wire mesh screen material is a versatile metal screening solution commonly used for ventilation protection, filtration support, and physical barriers in construction and industrial environments. It is designed to allow airflow and visibility while preventing unwanted objects, insects, or small animals from passing through.

This type of metal screen is widely applied in residential buildings, commercial facilities, agricultural structures, and industrial equipment. Thanks to its stable structure and long service life, metal screening has become a preferred alternative to plastic or fiberglass screens in projects that require durability and consistent performance.

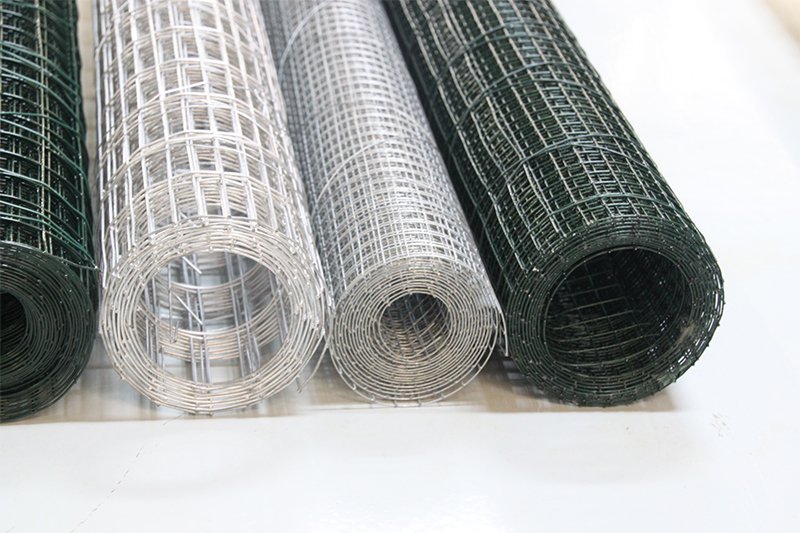

2. Material Options and Surface Treatment

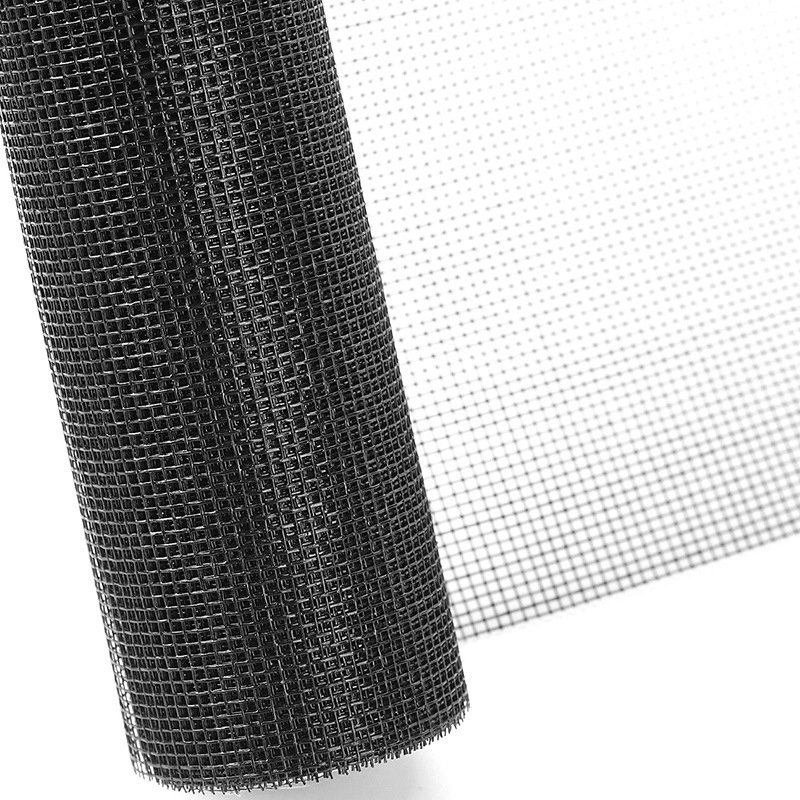

Metal screening is manufactured using high-quality steel wire to ensure strength and dimensional stability. Common material options include galvanized steel, stainless steel, and PVC-coated wire. Each option is selected based on environmental conditions and corrosion resistance requirements.

Galvanized steel screens are suitable for general indoor and outdoor applications, while stainless steel versions perform well in humid, coastal, or food-related environments. PVC-coated screens provide additional surface protection and improved appearance. Different surface treatments help extend service life and reduce maintenance costs over time.

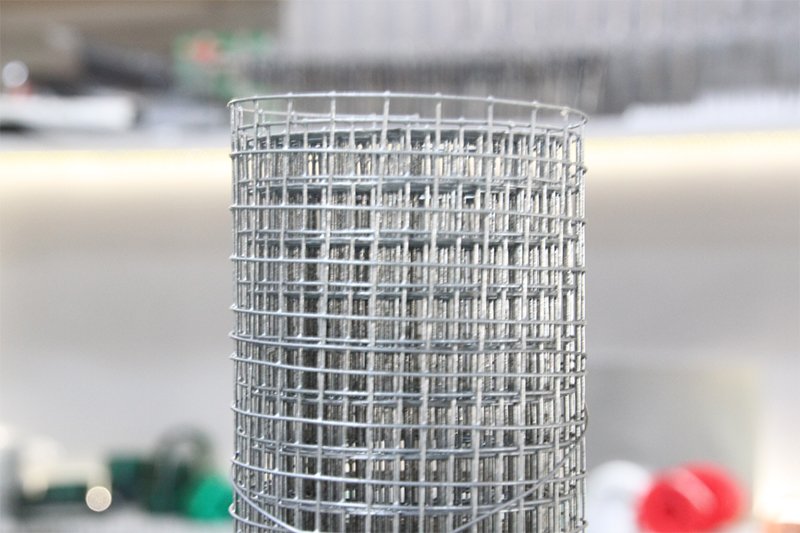

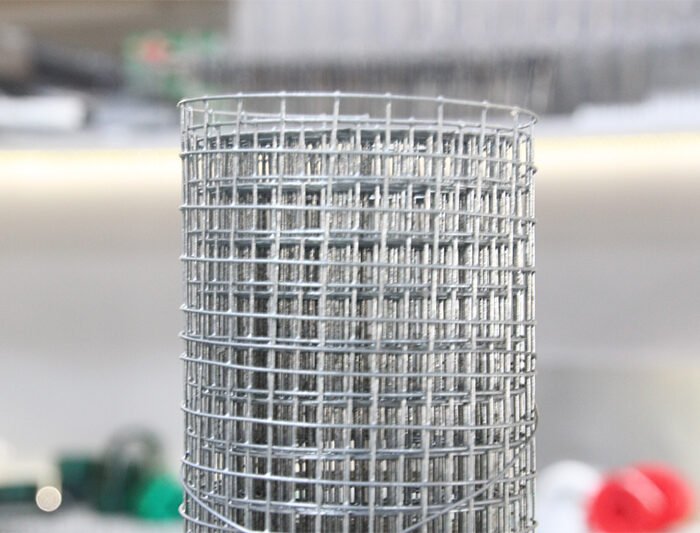

3. Structure and Performance Features

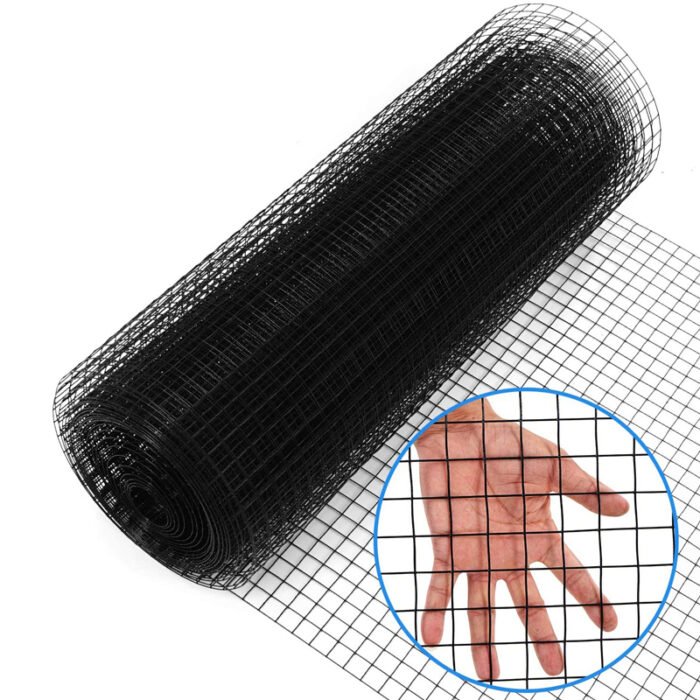

The screen structure is produced through woven or welded processes, ensuring uniform mesh openings and reliable mechanical strength. Wire diameter and opening size can be adjusted to meet different functional needs, such as fine screening for pest prevention or larger apertures for airflow and equipment guarding.

Compared with non-metal alternatives, steel-based screening offers superior resistance to impact, deformation, and environmental exposure. It maintains shape under pressure and does not sag, crack, or deteriorate easily, even during long-term use in demanding conditions.

4. Applications and Supply Advantages

Metal screening materials are easy to cut, shape, and install on wood, concrete, or metal frames. Common fixing methods include screws, nails, clips, or custom frames, making them suitable for both new construction and renovation projects.

As a factory-direct supplier, we provide stable production capacity, consistent quality control, and flexible customization for bulk orders. Buyers can specify mesh size, wire diameter, roll or sheet dimensions, and packaging to match local market requirements. Choosing a reliable wire mesh screen material supplier helps ensure long-term performance, cost efficiency, and smooth project execution.

Factory Strength & Manufacturing Expertise

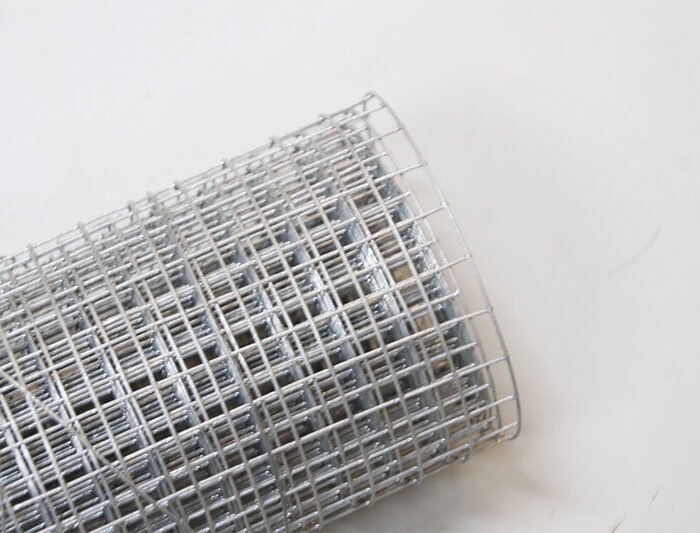

I operate a wire mesh manufacturing facility with years of hands-on experience in producing welded wire mesh and coated wire products for global markets. From raw wire drawing to welding, PVC coating, and final inspection, I control every production step to ensure stable quality and consistent specifications.

The factory uses automated welding machines and uniform coating lines to achieve precise mesh openings, strong weld points, and smooth, even PVC coverage. Each batch undergoes strict quality checks for wire diameter, coating adhesion, corrosion resistance, and dimensional accuracy before packing.

I also place strong emphasis on packaging and logistics. Reinforced cartons and palletized loading reduce deformation and damage during transport. With flexible OEM options, stable supply capacity, and fast response on custom requirements, the factory supports both small trial orders and large-volume projects with reliable lead times.

Contact Us

If you need technical advice, specifications, or pricing for wire mesh products, I am ready to assist you directly. Share your application details, required sizes, and quantity, and I will help you choose the right solution efficiently.

WhatsApp: +18830227875

Website: https://tswiremesh.com/

Feel free to contact me for fast quotations, custom orders, or factory support.