Stainless Steel Wire Rope: Strength, Safety, and Long-Term Performance

Stainless steel wire rope is widely used across construction, marine, architectural, and industrial applications where high strength, corrosion resistance, and reliability are critical. Compared with ordinary steel cables, stainless wire rope offers superior durability and appearance, making it a preferred choice for both functional and decorative uses. In this article, we explain why stainless wire rope is trusted worldwide, its key advantages, and how to choose the right type for your project.

What Makes Stainless Wire Rope Different?

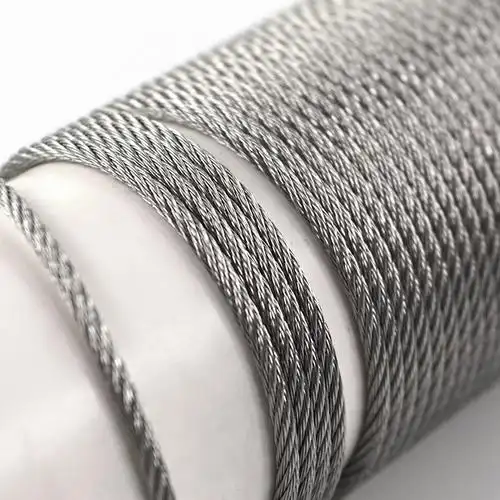

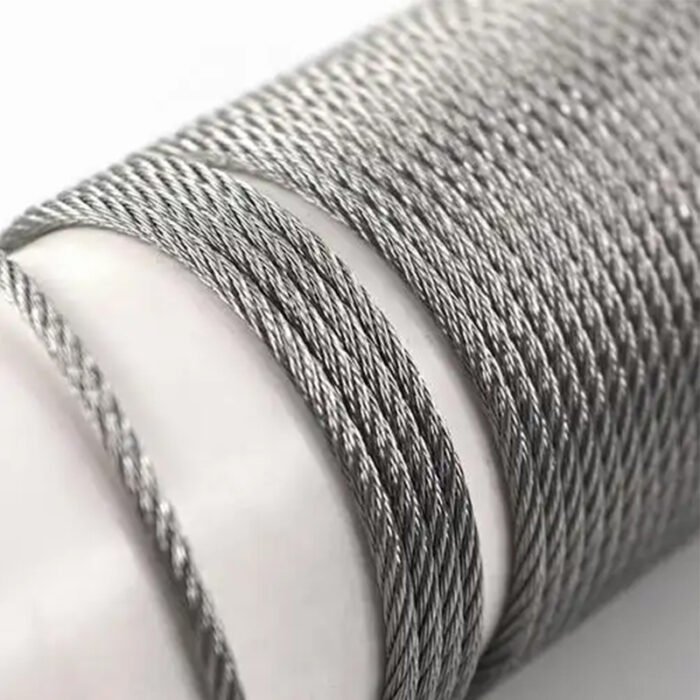

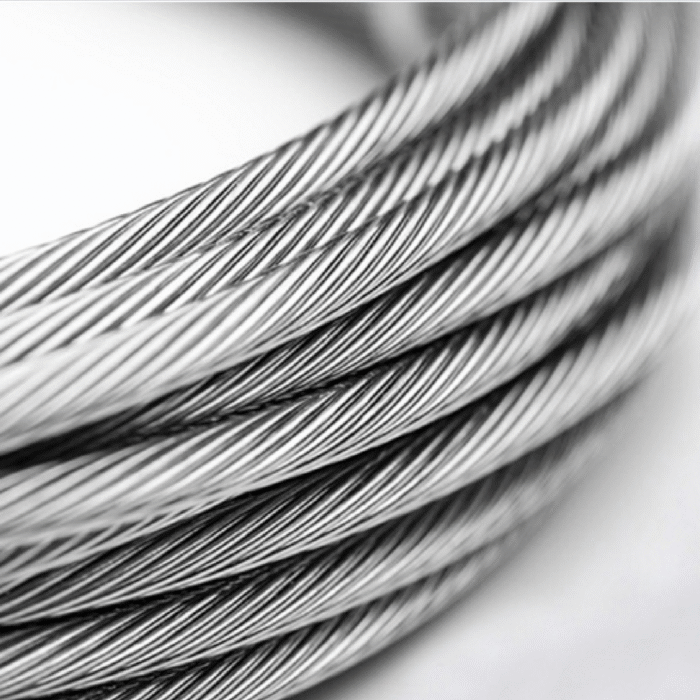

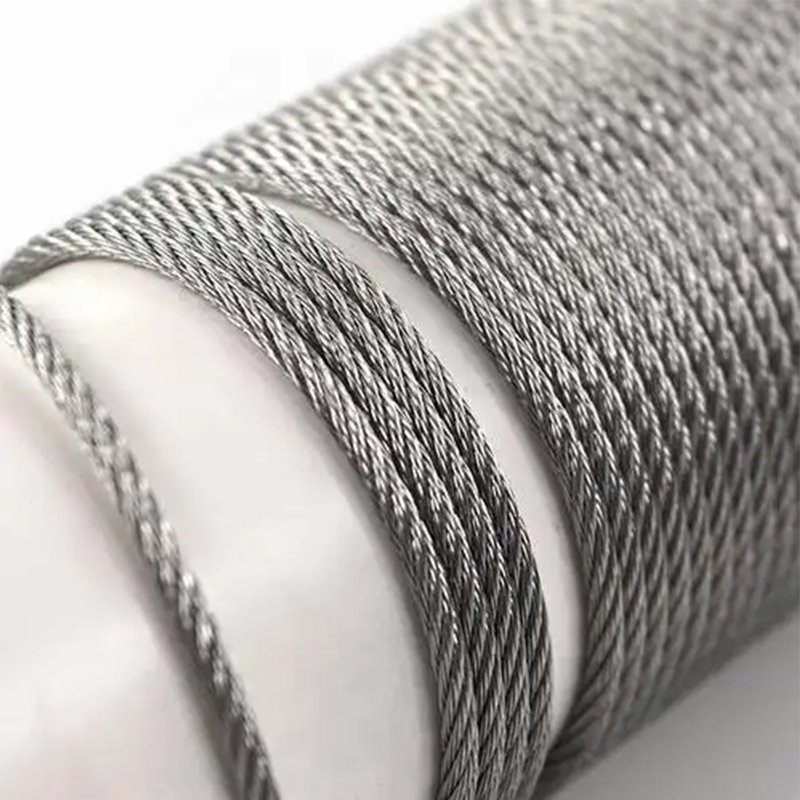

Stainless wire rope is manufactured by twisting multiple stainless steel wires into strands and then helically winding those strands into a strong cable structure. Common grades include 304 and 316 stainless steel, each offering distinct performance benefits.

Thanks to its alloy composition, stainless cable resists rust, oxidation, and chemical corrosion far better than galvanized alternatives. This makes it suitable for harsh environments such as coastal areas, chemical plants, food-processing facilities, and outdoor architectural installations where appearance and hygiene matter.

Key Product Advantages

High-quality stainless wire rope delivers a combination of mechanical strength and long service life.

Main selling points include:

-

Excellent corrosion resistance: Ideal for marine, humid, and outdoor environments

-

High tensile strength: Maintains load-bearing capacity under continuous stress

-

Smooth surface finish: Clean appearance for railing, balustrade, and decorative use

-

Low maintenance: No frequent recoating or replacement required

-

Safety and stability: Uniform strand construction ensures consistent performance

Whether used for lifting, suspension, fencing, or safety systems, stainless cables provide dependable performance over time.

Typical Applications Across Industries

Because of its versatility, stainless wire rope is used in a wide range of industries:

-

Architectural railings, stair balustrades, and cable infill systems

-

Marine rigging, yacht accessories, and dock installations

-

Industrial lifting, hoisting, and safety lines

-

Agricultural and fencing applications requiring rust resistance

-

DIY and decorative projects where clean aesthetics matter

In environments where galvanized wire may degrade quickly, stainless cable remains stable and visually appealing.

Buying Guide: How to Choose the Right Wire Rope

Selecting the correct wire rope depends on several technical factors:

-

Material grade:

-

304 stainless steel for general outdoor and indoor use

-

316 stainless steel for marine or highly corrosive environments

-

-

Construction type:

Common constructions include 7×7 and 7×19, offering different levels of flexibility and strength. -

Diameter and load rating:

Choose based on working load requirements and safety factors. -

Surface and packaging:

Ensure smooth finishing and export-grade packaging to prevent deformation during transport.

Choosing the right specifications ensures safety, longevity, and cost efficiency.

Product Specifications

| Parameter | Description |

| Material | Stainless steel (AISI 304 / AISI 316 / 316L optional) |

| Structure | 1×7, 1×19, 7×7, 7×19 (custom constructions available) |

| Diameter Range | 0.3 mm – 20 mm (custom diameters supported) |

| Applications | Lifting & rigging, railing systems, marine use, construction, agriculture, fencing, DIY projects |

Factory-Direct Supply from TS Wire Mesh

As an experienced wire mesh and wire products manufacturer, TS Wire Mesh supplies stainless steel cables, welded wire mesh, hexagonal wire mesh, iron wire, and related metal products to global markets. We offer stable quality control, customized specifications, and export-ready packaging.

📲 Contact us on WhatsApp: +86 18830227875

Get factory pricing, technical support, and fast quotations directly from our team.

FAQ – Stainless Steel Wire Rope

1. What is the difference between 304 and 316 stainless steel wire rope?

304 stainless steel offers excellent corrosion resistance and is suitable for general industrial and indoor applications.

316 stainless steel contains molybdenum, providing superior resistance to saltwater and chemicals, making it ideal for marine and coastal environments.

2. Which wire rope structure should I choose?

-

1×19: High strength, low flexibility, ideal for railings and architectural use

-

7×7: Balanced strength and flexibility, commonly used for control cables

-

7×19: Highly flexible, suitable for lifting, pulleys, and dynamic applications

Our team can help recommend the best structure based on your use case.

3. Can you supply custom sizes or special specifications?

Yes. We support custom diameters, constructions, lengths, and packaging to meet different market and project requirements. OEM and bulk orders are welcome.

4. Is stainless steel wire rope suitable for outdoor use?

Absolutely. Stainless steel wire rope is rust-resistant, weather-resistant, and UV-stable, making it suitable for long-term outdoor and harsh-environment applications.

5. How is quality controlled for export orders?

All wire ropes undergo strict tensile testing, diameter inspection, surface checks, and packaging verification before shipment, meeting export-grade quality standards.