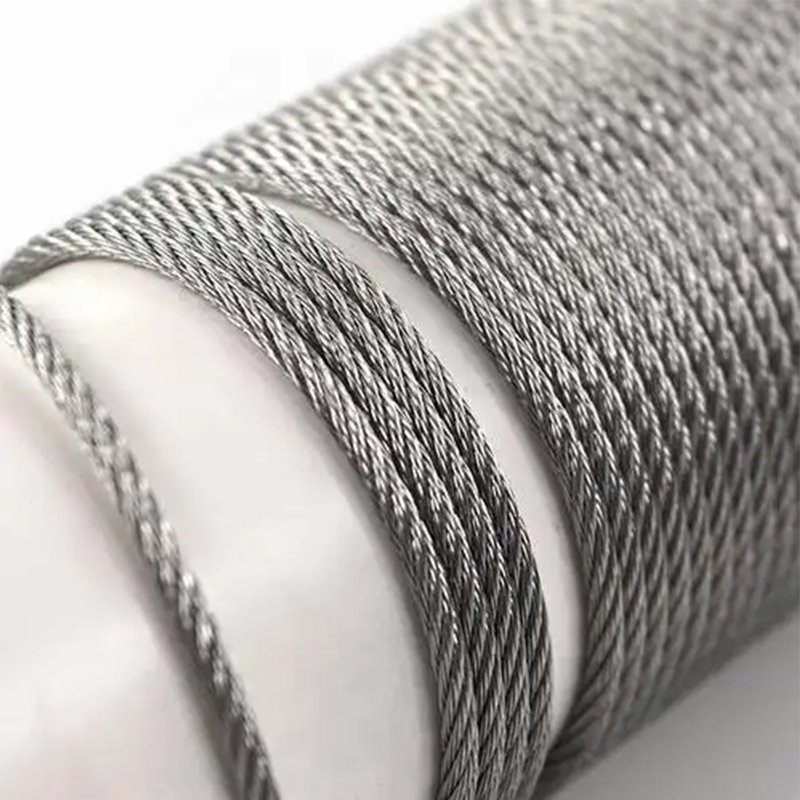

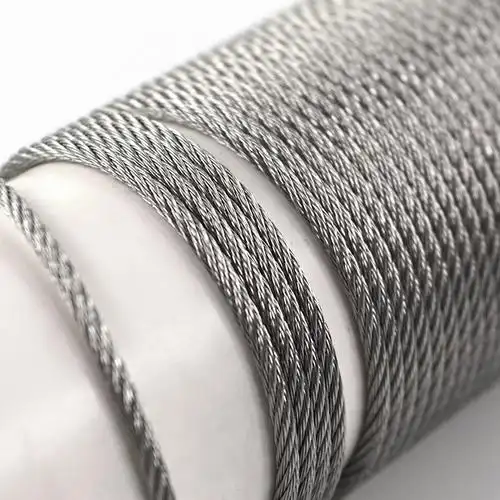

Product Overview

Galvanized steel wire rope is widely used in industrial, agricultural, and construction applications due to its high tensile strength, abrasion resistance, and cost efficiency. The zinc coating forms a protective barrier that helps prevent rust and corrosion, extending service life in outdoor and moderately corrosive environments.

Compared with stainless steel wire rope, galvanized rope offers a more economical solution while maintaining excellent mechanical performance, making it ideal for large-scale projects and heavy-duty use.

Key Advantages

-

Strong Tensile Performance

Manufactured from high-carbon steel, the wire rope delivers excellent load-bearing capacity and resistance to deformation. -

Corrosion Protection

Hot-dip galvanizing ensures uniform zinc coverage, protecting the steel core from moisture, rain, and mild chemical exposure. -

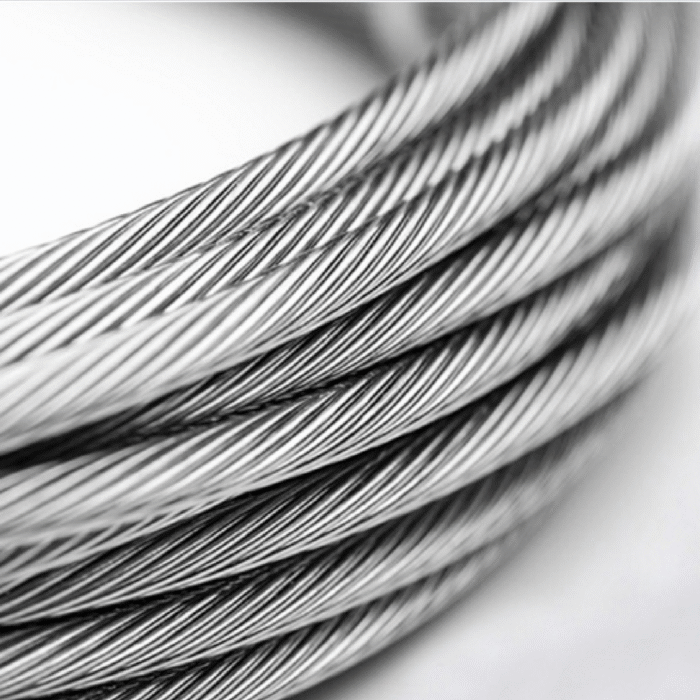

Multiple Structures Available

From rigid 1×19 constructions to flexible 7×19 designs, the rope can be matched to static or dynamic applications. -

Cost-Effective for Bulk Use

Lower material cost compared to stainless steel makes it suitable for fencing systems, farm equipment, and infrastructure projects. -

Export-Grade Manufacturing

Produced under strict quality control with tensile testing, diameter inspection, and secure packaging for international shipping.

-

-

Galvanized vs Stainless Steel Wire Rope: Which Should You Choose?

Choosing between galvanized and stainless steel wire rope depends on environment, budget, and performance requirements. Below is a practical comparison to guide purchasing decisions.

1. Material & Corrosion Resistance

Galvanized Steel Wire Rope

Galvanized wire rope is made from high-carbon steel coated with a zinc layer. This coating protects the steel from moisture and mild corrosion, making it suitable for outdoor, agricultural, and construction use. However, the zinc layer can wear over time in highly corrosive or coastal environments.Stainless Steel Wire Rope

Stainless steel wire rope is manufactured from stainless steel alloys (commonly 304 or 316). It offers excellent corrosion and oxidation resistance without relying on surface coatings. Grade 316 performs especially well in marine, coastal, and chemical environments.

2. Strength & Mechanical Performance

-

Galvanized wire rope generally provides higher tensile strength at a lower cost, making it ideal for heavy loads and large-scale projects.

-

Stainless steel wire rope offers stable strength with superior resistance to fatigue and temperature variation, but usually at a higher price point.

For most industrial and fencing applications, galvanized wire rope delivers more than enough mechanical performance.

3. Flexibility & Structure Options

Both types are available in multiple constructions such as 1×19, 6×7, 6×19, and 7×19.

-

Galvanized rope is often chosen for static or semi-dynamic loads like fencing, guy wires, and hoisting.

-

Stainless steel rope is preferred for moving systems, architectural tension cables, and decorative installations where flexibility and appearance matter.

-

-

-

4. Cost & Maintenance

-

Factor Galvanized Wire Rope Stainless Steel Wire Rope Initial Cost Lower Higher Maintenance Moderate Minimal Service Life Long (normal conditions) Very long (harsh conditions) Best for Bulk Projects √ Yes × Limited -

If cost efficiency is a priority, galvanized wire rope is the practical choice. Stainless steel is better for long-term, low-maintenance applications.

-

-

5. Typical Applications

Galvanized Steel Wire Rope

-

Fencing systems

-

Agriculture and livestock equipment

-

Construction lifting and rigging

-

Mining and transportation

-

Power and telecom support lines

Stainless Steel Wire Rope

-

Marine and offshore projects

-

Coastal fencing and balustrades

-

Food processing facilities

-

Architectural and decorative uses

-

Chemical and high-humidity environments

-

FAQ – Galvanized Steel Wire Rope

1. What is the difference between hot-dip galvanized and electro-galvanized wire rope?

Hot-dip galvanized wire rope has a thicker zinc coating and better corrosion resistance, making it suitable for outdoor and heavy-duty use. Electro-galvanized rope has a smoother finish but a thinner coating, best for indoor or light-duty applications.

2. Is galvanized steel wire rope suitable for outdoor use?

Yes. It performs well in outdoor environments such as farms, construction sites, and fencing systems. For coastal or highly corrosive areas, stainless steel wire rope is recommended.

3. Which wire rope structure is best for lifting?

Structures like 6×19 or 7×19 provide better flexibility and fatigue resistance, making them suitable for lifting, pulleys, and winches.

4. Can you provide custom lengths and packaging?

Yes. We offer custom cutting, coil sizes, wooden reel packaging, and OEM labeling according to customer requirements.

5. What industries commonly use galvanized steel wire rope?

It is widely used in construction, agriculture, fencing, marine mooring, mining, transportation, and industrial machinery.

Factory-Direct Supply from TS Wire Mesh

As an experienced wire mesh and wire products manufacturer, TS Wire Mesh supplies stainless steel cables, welded wire mesh, hexagonal wire mesh, iron wire, and related metal products to global markets. We offer stable quality control, customized specifications, and export-ready packaging.

📲 Contact us on WhatsApp: +86 18830227875

Get factory pricing, technical support, and fast quotations directly from our team.