Concrete reinforcing welded wire mesh is one of the most widely used materials for strengthening structural concrete in commercial, residential, and industrial construction. It provides enhanced crack control, increased tensile capacity, and reliable load distribution across slabs, sidewalks, foundations, and retaining walls.

The manufacturing process begins with high-quality low-carbon steel wire. The wires are accurately aligned and welded together by automated machinery to ensure consistent intersections and precise spacing. This uniformity helps prevent weak points in concrete, improving long-term performance under pressure and temperature changes. Whether used in floor slabs or pavement reinforcement, this type of steel grid significantly improves structural stability.

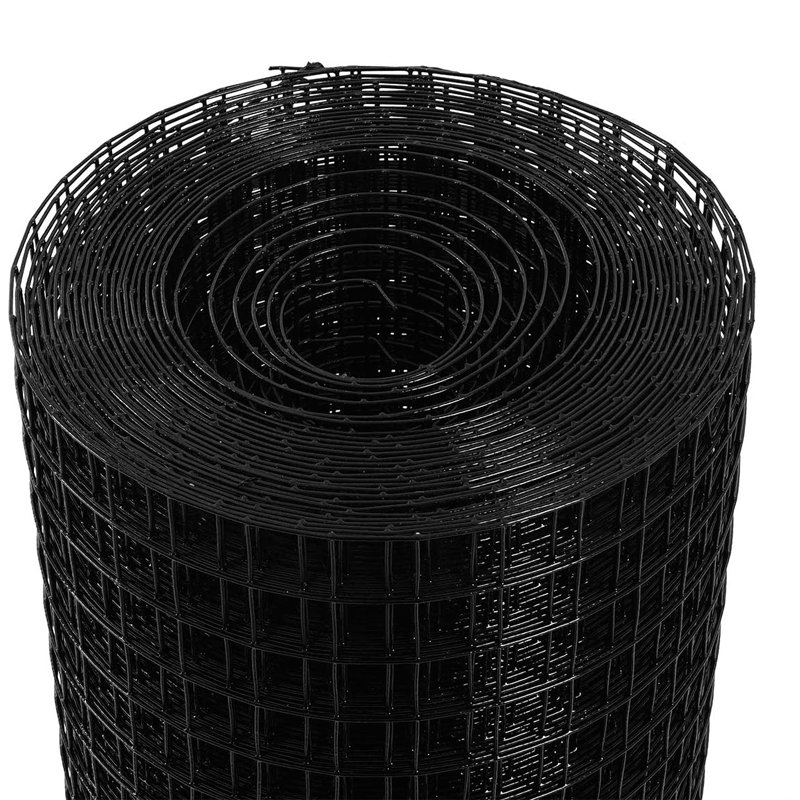

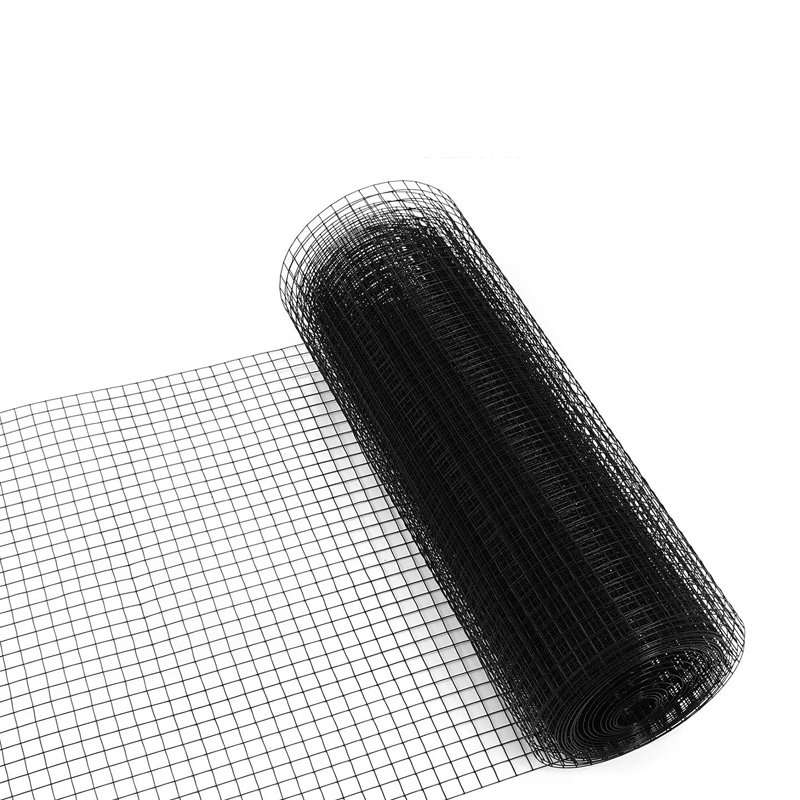

Surface treatments also contribute to durability. Most contractors choose plain black steel for indoor projects or galvanized options for outdoor applications where moisture exposure is common. Galvanized mesh provides additional corrosion resistance, extending lifespan and lowering maintenance costs.

A dependable concrete reinforcing welded wire mesh supplier will offer multiple spacing patterns, wire diameters, and sheet sizes. Many construction plans require custom dimensions to reduce cutting waste and boost installation efficiency. Pre-cut panels, flattened sheets, and special reinforcement patterns are also available for engineering-specific layouts.

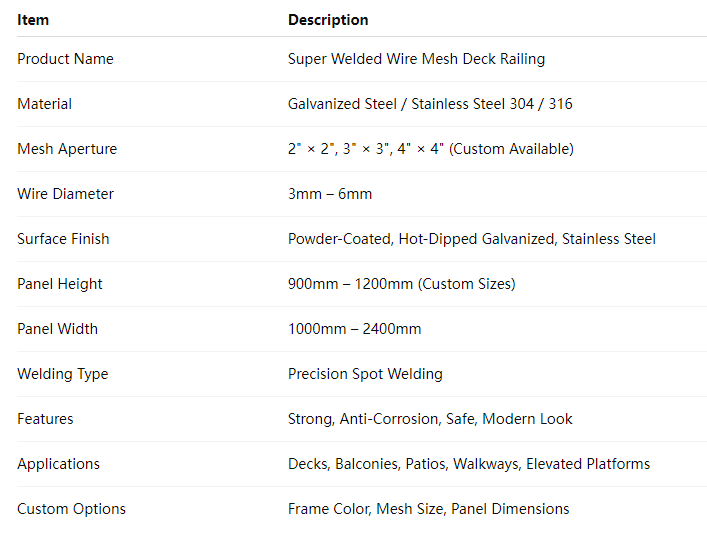

Below is a reference table containing common specifications.

Product Specification Table