Cage-Free Poultry Systems and Mesh Solutions for Modern Farms

cage free chicken farming has become a mainstream production model as poultry producers respond to animal welfare standards, consumer demand, and regulatory pressure. Compared with traditional confinement systems, cage-free operations require more thoughtful infrastructure design, especially in fencing, partitions, flooring support, and animal flow control.

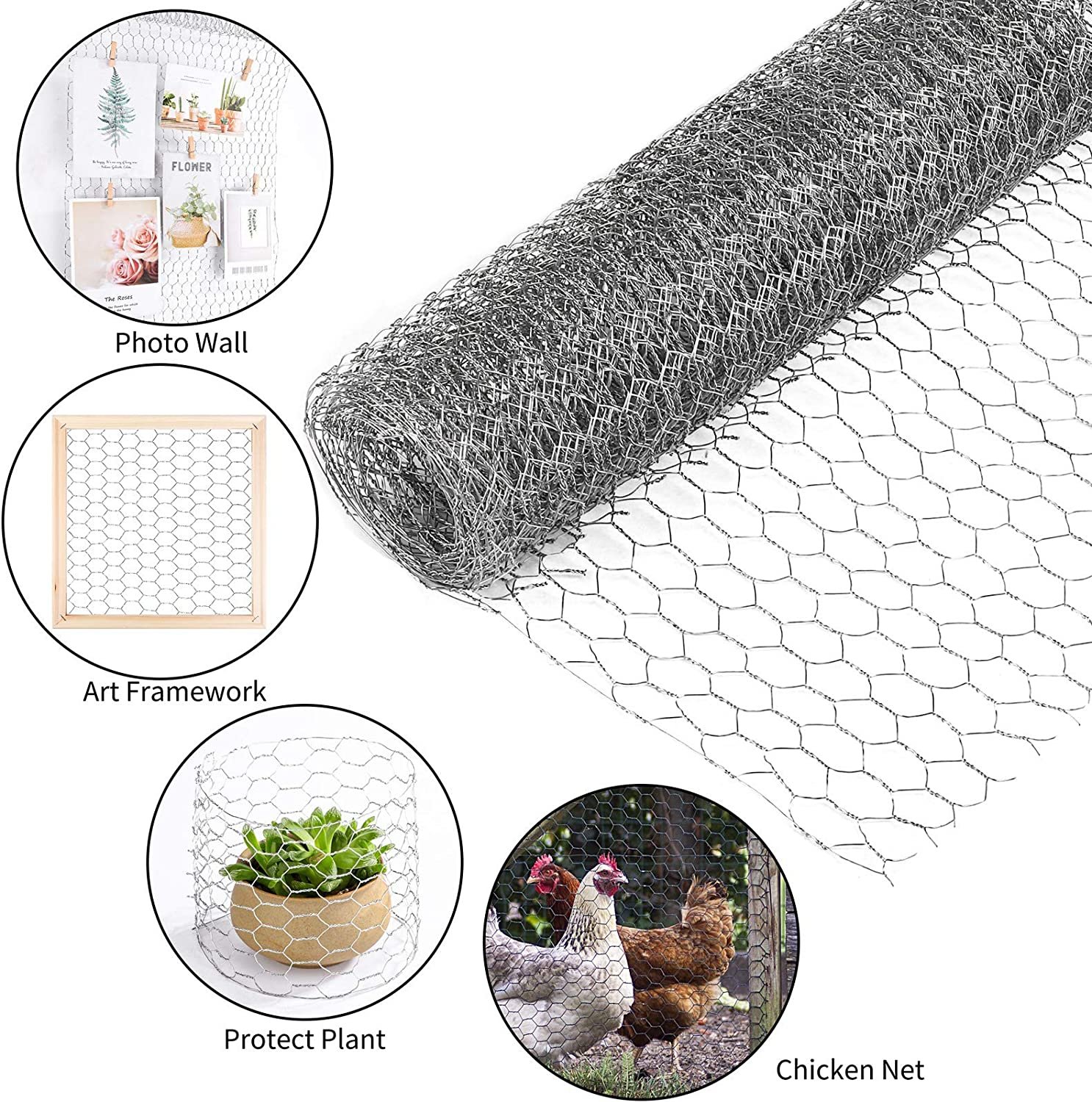

Wire mesh products—particularly hexagonal wire mesh—play a critical role in balancing freedom of movement with farm management efficiency.

1. Poultry Housing Models: Cage, Aviary, and Free-Range Systems

Modern poultry production generally falls into three housing categories.

Conventional cage systems focus on maximum stocking density and simplified management. While efficient in space usage, they restrict natural behavior and face increasing regulatory limitations.

Aviary systems allow birds to move vertically and horizontally within multi-level structures. They require strong internal partitions, reliable floor support, and durable barriers to separate functional zones.

Free-range systems provide the highest level of movement, combining indoor housing with outdoor access. These systems depend heavily on perimeter fencing and internal zoning to protect birds while maintaining biosecurity.

Among these models, cage-free operations place the greatest demand on adaptable, corrosion-resistant mesh materials that can perform reliably in both indoor and semi-outdoor environments.

2. Why Hexagonal Wire Mesh Fits Cage-Free Poultry Environments

Hexagonal wire mesh, commonly known as poultry netting, is one of the most widely used materials in open poultry systems. Its woven structure distributes stress evenly, making it flexible yet resilient under constant bird movement.

Compared with rigid fencing, hexagonal netting adapts well to uneven floors and curved layouts. This is particularly useful in open barns and outdoor runs where ground conditions are not perfectly level.

For poultry welfare, the smooth woven intersections reduce injury risk, while the open structure ensures airflow and visibility. These characteristics make hexagonal netting a practical choice for partitions, ground barriers, and outdoor enclosures in welfare-oriented poultry farms.

3. Types of Hexagonal Wire Mesh for Poultry Applications

Different poultry environments require different mesh specifications.

Lightweight galvanized hexagonal netting is often used for internal partitions and temporary separation areas. It is easy to install and economical for large coverage areas.

Heavier gauge galvanized netting offers increased durability and is commonly used for perimeter fencing and predator protection. Its tighter weave helps prevent intrusion from small animals.

PVC-coated hexagonal wire mesh adds an extra corrosion barrier, making it suitable for humid regions or farms with frequent wash-down routines. The coating also improves service life and reduces long-term maintenance costs.

Selecting the right type depends on bird density, environmental exposure, and project lifespan.

4. Role of Welded Wire Mesh in Cage-Free Farm Structures

While hexagonal netting provides flexibility, welded wire mesh delivers structural stability. In cage-free poultry houses, welded mesh is frequently used for fixed partitions, equipment guards, and reinforced flooring zones.

The rigid intersections maintain consistent spacing, making welded mesh ideal for areas that require precise separation or load-bearing support. Compared with woven netting, it resists deformation under repeated stress.

In practice, many poultry projects combine welded mesh for structural elements with hexagonal netting for open enclosures, achieving both durability and adaptability.

chicken cage portable

5. Integrated Mesh Solutions for Efficient Cage-Free Operations

Successful cage-free poultry systems rely on coordinated infrastructure rather than a single product. Using flexible netting for movement zones and rigid mesh for structural areas allows farms to optimize both welfare and efficiency.

In the middle of these solutions, cage free chicken farming benefits from mesh systems that support bird behavior while simplifying management tasks such as cleaning, zoning, and biosecurity control.

For large-scale operations, standardized mesh specifications and consistent supply are essential to maintain uniform farm layouts across multiple houses.

B2B Conversion Section – Factory Supply & Cooperation (≈800 chars)

Looking for a reliable wire mesh solution for cage-free poultry projects?

We are a direct manufacturer specializing in hexagonal wire mesh and welded wire mesh for agricultural and livestock applications.

Our factory offers:

-

Multiple hexagonal mesh types for poultry housing and outdoor runs

-

Stable galvanized and PVC-coated production lines

-

Consistent quality for bulk and project orders

-

OEM specifications tailored to regional farm standards

With years of export experience, we support wholesalers, farm contractors, and poultry equipment suppliers with efficient production and professional technical guidance.

📲 WhatsApp: +86 18830227875

Contact us today to discuss your poultry project requirements and receive a fast quotation.

Product Information Table (Hexagonal Chicken Wire)

| Attribute | Description |

| Material | Galvanized iron wire with PVC coating |

| Weaving Type | Hexagonal twisted wire mesh |

| Surface Treatment | Hot-dip galvanized + PVC coated |

| Wire Diameter | 0.6–1.2 mm (custom options available) |

| Mesh Opening | Hexagonal mesh, commonly 1″, 1.5″, 2″ |

| Roll Size | Customized width and length available |

| Color Options | Green, black, or customized |

| Main Applications | Poultry fencing, garden protection, plant support, animal enclosures |

FAQ – Frequently Asked Questions (Hexagonal Wire Mesh)

Q1: What is the main difference between hexagonal chicken wire and welded wire mesh?

Hexagonal chicken wire is woven with twisted strands, making it more flexible and easier to bend, while welded mesh is rigid. Chicken wire is better for lightweight fencing and plant support.

Q2: Is PVC-coated chicken wire suitable for outdoor use?

Yes. The PVC coating protects the galvanized wire from moisture, soil contact, and UV exposure, significantly extending its service life outdoors.

Q3: Can hexagonal chicken wire be used as a trellis for plants?

Absolutely. Its flexible structure makes it ideal for climbing plants, flowers, and vegetable vines while allowing natural growth and airflow.

Q4: Is this type of chicken wire safe for animals and plants?

Yes. The twisted hexagonal structure and smooth coating reduce sharp edges, making it safer for poultry, pets, and garden plants.

Q5: Can I cut and connect multiple rolls together?

Yes. Chicken wire can be easily cut with standard wire cutters, and multiple rolls can be joined to cover larger areas without waste.