Livestock wire panels play a critical role in modern animal farming, especially for customers looking for strong, reliable, and cost-effective fencing solutions. As one of the hot-selling products in agricultural fencing, these panels are widely used for cattle, sheep, goats, horses, and mixed livestock enclosures where durability and safety are non-negotiable.

Why Livestock Farms Rely on Wire Panels

Compared with traditional wooden fences or lightweight netting, steel wire panels provide a much higher level of structural stability. Farm animals generate constant pressure through pushing, leaning, and movement. A well-designed metal panel system can absorb impact without bending or breaking, maintaining fence integrity over long periods.

Open wire construction also allows clear visibility and airflow, which helps reduce animal stress and makes daily management easier. Farmers can quickly monitor livestock conditions while maintaining secure boundaries.

Material and Structural Advantages

High-quality wire panels are typically manufactured from high-tensile steel wire with hot-dip galvanizing or heavy zinc coating. This process forms a protective layer that resists rust, moisture, and corrosion, even in harsh outdoor environments such as grasslands, paddocks, and open pastures.

The panel structure uses evenly spaced horizontal and vertical wires to distribute force evenly across the surface. Reinforced weld points or fixed joints ensure the panel maintains shape when exposed to repeated impact from large animals. This combination of material strength and smart engineering significantly extends service life and reduces replacement frequency.

Key Product Selling Points

For buyers comparing fencing options, metal wire panels stand out due to several practical benefits:

-

High Impact Resistance: Designed to withstand pressure from cattle, horses, and other large animals

-

Long Outdoor Lifespan: Galvanized finish protects against rain, humidity, and soil contact

-

Easy Installation: Panels can be fixed to steel posts or wooden posts with minimal tools

-

Low Maintenance: No painting or frequent repairs required

-

Versatile Use: Suitable for permanent fencing, temporary enclosures, and sectional farm layouts

These features make wire panel fencing one of the most economical long-term solutions for livestock management.

Applications Across Different Livestock Types

Wire panel fencing adapts well to various agricultural scenarios. In cattle and horse farms, panels provide strong perimeter control and reduce the risk of animals escaping. For sheep and goats, tighter spacing helps prevent animals from slipping through while still maintaining visibility.

Panels are also commonly used around barns, feeding zones, loading areas, and pasture divisions. Their modular design allows farmers to expand or reconfigure layouts as herd size changes.

Buying Guide: How to Choose the Right Panels

Before purchasing, buyers should evaluate several key factors:

-

Wire Diameter: Thicker wire offers greater strength and longer service life

-

Panel Size: Choose height and length based on animal size and enclosure layout

-

Surface Treatment: Hot-dip galvanized panels are recommended for outdoor and long-term use

-

Joint Type: Welded or fixed joints should be smooth and evenly reinforced

-

Installation Environment: Consider soil conditions, wind exposure, and animal behavior

Selecting the right specifications ensures optimal performance and minimizes future maintenance costs.

A Reliable Choice for Long-Term Farm Fencing

When properly selected and installed, livestock wire panels provide a balanced solution combining strength, durability, and flexibility. They support efficient farm operations while protecting animals and property. For farms focused on long-term value and dependable performance, metal wire panel fencing remains a proven and trusted choice in agricultural infrastructure.

Factory Advantages

With years of manufacturing experience in wire mesh and metal fencing products, our factory specializes in supplying reliable solutions for agriculture, construction, and security applications worldwide. We operate a complete in-house production system covering wire drawing, welding, galvanizing, surface coating, and final inspection, ensuring stable quality from raw material to finished goods.

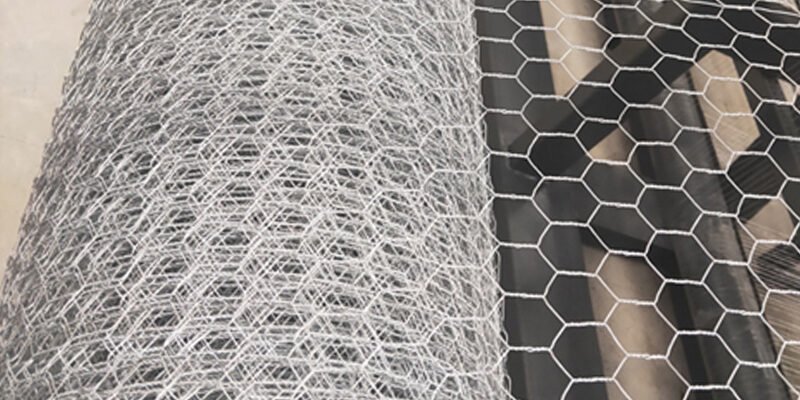

Our production lines focus on galvanized welded wire mesh, hexagonal wire mesh, livestock panels, chicken wire, fencing wire, and related metal products. By using carefully selected steel wire and advanced welding technology, we achieve consistent mesh openings, strong weld joints, and excellent structural stability. Hot-dip galvanizing and PVC coating processes are strictly controlled to deliver long-lasting corrosion resistance for outdoor use.

Quality control is a key advantage. Each batch undergoes dimensional checks, weld strength testing, and surface inspection before packing. We also invest in reinforced export packaging to reduce deformation and damage during long-distance transportation.

As an export-oriented factory, we understand international market requirements. We support customized specifications, flexible order quantities, and stable lead times, helping buyers reduce sourcing risks and control costs. Our products are widely shipped to markets in North America, Europe, Africa, and the Middle East for wholesalers, contractors, and distributors.

Reliable quality, practical pricing, and responsive communication make us a long-term manufacturing partner rather than just a supplier.

Contact us directly on WhatsApp: +86 18830227875

Get fast quotations, technical support, and customized wire mesh solutions for your market.

Recommended Products

-

Welded Wire Mesh

Durable mesh with uniform openings for fencing, garden trellises, and small animal enclosures.

View Product -

Razor Wire

High-strength wire suitable for farm, industrial, and security fencing. Provides long-lasting protection.

View Product -

Iron Wire

Versatile wire for construction, binding, and DIY projects. Strong, flexible, and easy to use.

View Product

Post a Comment