Industrial Steel and Wire for Manufacturing, Construction & More

Industrial steel and wire are essential materials for a wide range of applications in the manufacturing, construction, and agricultural industries. From iron wire for reinforcement to steel wire mesh for structural stability, industrial wire products provide both strength and flexibility.

This guide is for B2B buyers, including wholesalers, distributors, and contractors, looking to source high-quality wire products directly from manufacturers for large-scale projects.

Key Applications of Industrial Steel and Wire Products

Industrial steel and wire are used in various sectors, including:

-

Construction: Steel wire is used for reinforcing concrete, creating fences, and installing wire mesh for safety barriers.

-

Manufacturing: Wire products are used in creating industrial components, automotive parts, and machinery.

-

Agriculture: Steel wire is used in fencing for farms, gardens, and animal enclosures.

-

Infrastructure: Industrial steel wire is used for road construction, utility installations, and supporting structures.

Given the diverse applications, industrial wire products must meet specific strength, durability, and corrosion resistance standards.

Types of Industrial Steel and Wire Products

1. Steel Wire

Industrial steel wire is widely used for reinforcement, binding, and structural applications. Available in various diameters, steel wire provides flexibility and tensile strength, ensuring long-lasting performance.

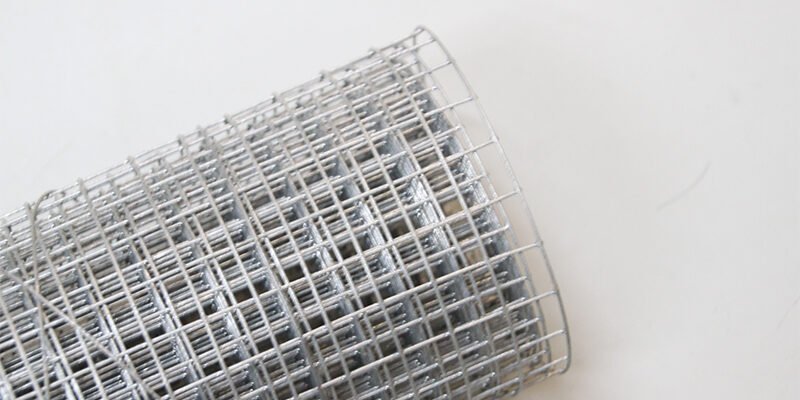

2. Welded Wire Mesh

Used for structural fencing, reinforcing concrete, or as safety barriers, welded wire mesh is manufactured by welding steel wires together to create a grid. It is known for its strength and uniformity.

3. Galvanized Wire

Galvanized steel wire offers excellent protection against corrosion, making it ideal for outdoor applications. Its zinc coating ensures the wire will not degrade under environmental stress, providing a longer service life.

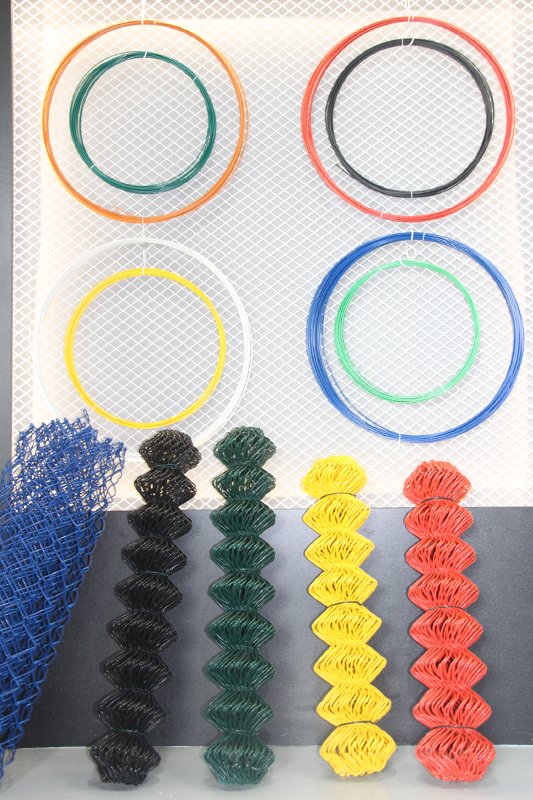

4. PVC Coated Wire

PVC-coated wire products are coated with a layer of PVC material to provide an additional layer of protection against the elements. This is ideal for environments that require enhanced corrosion resistance.

Factors to Consider When Sourcing Industrial Steel and Wire

When purchasing industrial steel and wire for large projects, B2B buyers should consider several factors to ensure the materials meet project needs and budget requirements:

1. Material Strength and Durability

The strength of steel wire or mesh is critical for ensuring long-term performance. Buyers should evaluate tensile strength, wire diameter, and material composition before making bulk orders.

2. Corrosion Resistance

For outdoor or high-moisture environments, it is essential to source galvanized wire or PVC-coated wire, which will resist rust and other forms of corrosion.

3. Customization

Many buyers require customized wire products to meet specific needs. Ensure that the manufacturer can provide custom mesh sizes, wire thickness, or coating options.

4. Cost and Bulk Discounts

For large orders, cost is always a significant factor. Working directly with a manufacturer often allows B2B buyers to benefit from bulk pricing and FOB pricing for competitive cost control.

Why Choose Factory-Direct Industrial Steel and Wire Supply?

Sourcing industrial steel and wire products directly from a manufacturer provides several advantages:

-

Consistent Quality Control: Direct manufacturing ensures that the wire products meet all required specifications, from material strength to finish.

-

Customization: Factories can accommodate custom orders, ensuring the wire meets project-specific needs.

-

Competitive Pricing: By cutting out middlemen, factory-direct sourcing allows for more competitive prices, particularly for large quantities.

-

Reliable Lead Times: Manufacturers often provide clearer lead times, helping buyers plan their projects more effectively.

-

Long-Term Supply: A reliable factory partner can provide ongoing supply for future projects, ensuring consistency and reliability.

How to Install Industrial Steel Wire Products in Large Projects

Installation of industrial steel wire products is a critical step to ensure the structural integrity of the project. Here are common installation applications:

-

Steel Wire for Reinforcement: Used in construction for reinforcing concrete, ensuring structural stability.

-

Welded Wire Mesh for Fencing: Ideal for perimeter security or safety barriers on construction sites.

-

PVC Coated Wire for Garden Fencing: Typically used in agricultural settings for long-lasting and corrosion-resistant fences.

In addition to steel and wire, Iron Nails and wire rope are essential for installation, helping to secure the wire and provide additional support for fences and mesh.

Contact Us for Bulk Orders and Custom Orders

For a quote or more information about our industrial steel and wire products, contact us today. We offer factory pricing, fast quotations, and tailored solutions for all your wire and mesh needs.

Factory Introduction – Professional Industrial Steel and Wire Manufacturer

TianSheng Welded Wire Mesh is a professional manufacturer specializing in industrial steel and wire products for global B2B markets. With years of experience in metal wire processing and mesh fabrication, the factory has established a complete production system covering raw material selection, wire drawing, galvanizing, welding, weaving, surface treatment, and export packaging.

The product range includes welded wire mesh, hexagonal wire mesh, square wire fencing, barbed wire, razor wire, galvanized iron wire, PVC coated wire, wire rope, and iron nail products. These materials are widely used in agriculture, construction, industrial fencing, infrastructure projects, and security applications. By offering a full product portfolio, TianSheng Wire Mesh enables buyers to source multiple fencing and wire solutions from one reliable manufacturer, improving compatibility and reducing procurement complexity.

The factory is equipped with modern automated production lines and experienced technical staff, allowing precise control over wire diameter tolerance, mesh opening size, welding strength, zinc coating weight, and surface finish quality. From standard specifications to customized designs, production can be adjusted according to different regional standards and project requirements. OEM services, private labeling, and customized packaging are also supported for wholesalers and distributors.

Quality control is a core priority throughout the manufacturing process. From incoming raw steel wire inspection to in-process monitoring and final product checks, strict internal standards are applied to ensure consistent mechanical performance and corrosion resistance. For export orders, the factory supports sample approval, detailed specification confirmation, and third-party inspection when required by buyers.

In terms of logistics and export support, TianSheng Wire Mesh has extensive experience serving customers in Africa, the Middle East, South America, Southeast Asia, and other international markets. Products are packed in export-standard bundles, rolls, pallets, or containers, designed to optimize loading efficiency and reduce transportation damage. Complete export documentation and flexible Incoterms such as FOB and CIF are available to meet different buyer needs.

Beyond manufacturing, the company focuses on building long-term partnerships with B2B clients. By providing stable supply capacity, competitive factory pricing, responsive communication, and technical support, TianSheng Wire Mesh helps customers improve project efficiency and strengthen their market competitiveness. Whether for large-scale infrastructure projects or continuous wholesale distribution, the factory aims to be a reliable and professional partner in industrial steel and wire supply.

Post a Comment