How Barbed Wire Is Made: A Complete Guide to Quality, Strength, and Performance

Understanding how barbed wire is made helps buyers choose fencing that truly delivers strength, safety, and long-term performance.

As someone deeply involved in steel wire and barbed-wire production, I always focus on material quality and manufacturing accuracy, because these factors directly determine whether the fence can withstand tension, harsh weather, and continuous outdoor exposure.

The process begins with material selection. High-carbon steel wire serves as the foundation of the entire manufacturing line. It provides core tensile strength and, after proper drawing, offers the uniform hardness required for twisting. High-quality wire handles tension exceptionally well, while inferior steel often results in breakage or loose barbs. To improve corrosion resistance, I prefer galvanized steel with a thicker zinc coating, ensuring better protection against moisture and rain.

The next stage is wire drawing. The wire passes through multiple dies, reducing its diameter and achieving consistent elasticity. This step directly affects how smoothly the twisting process operates and how firmly the barbs attach. Inconsistent wire diameter leads to uneven barb spacing and reduced overall strength.

Once the wire reaches the desired specifications, the barbs are formed. A barbed-wire machine cuts smaller wires into precise lengths and shapes each tip into a sharp angle for effective deterrence. Even, well-shaped barbs that grip the main wire securely are one of the clearest indicators of high-quality fencing.

Twisting is the core of the entire manufacturing process. It also reveals a factory’s true technical capability. The main wire and barb wires twist together at controlled intervals, ensuring each barb stays fixed firmly without slipping. Many first-time buyers overlook the importance of consistent twisting pitch, but I maintain strict control over this detail because uneven spacing causes irregular protection coverage and poor durability.

Understanding how barbed wire is made allows buyers to recognize essential quality indicators—stable tensile strength, tightly secured barbs, high-zinc galvanization, and precise twisting intervals.

From farm fencing and ranch boundaries to security zones and industrial protection, barbed wire performs effectively only when the materials and craftsmanship meet high standards. Knowing the manufacturing steps empowers every buyer to make smarter, more reliable purchasing decisions.

✅ To help you understand pricing differences, here is a reference table:

| Razor Barbed Wire Product Data Table | |||

| Material | Core Wire | Coating | Typical Price lmpact |

| Galvanized Steel | 2.5-3.0 mm | Zinc-coated | Medium cost, gooddurability |

| Hot-Dip Galvanized | 2.5 mm | Heavy zinc layer | Higher cost, long service life |

| Stainless Steel 304 | 2.5 mm | No coating needed | Highest cost, premium lifespan |

| PVC Coated | 2.5 mm | PVC + zinc | Medium-high cost,weather resistant |

Buying Guide – Secure Your Barbed Wire Today

When selecting barbed wire, I always focus on three key factors: material quality, barb consistency, and twisting accuracy. High-carbon or galvanized steel ensures long-term strength and resistance to corrosion. Check that barbs are evenly spaced and tightly fixed to the main wire, and ensure the twisting intervals are precise for maximum durability.

Consider whether rolls or pre-cut panels suit your installation. Rolls offer flexibility for custom lengths, while panels simplify quick setups. PVC or heavy galvanization can provide extra protection in harsh environments. Investing in high-quality fencing now prevents future maintenance and replacement costs.

For professional advice, personalized recommendations, or to place an order, contact me directly on WhatsApp: +18830227875. I can help you choose the right specifications and ensure your barbed wire meets your exact needs. Don’t wait—secure durable, high-quality fencing today and protect your property with confidence.

Recommended Products

-

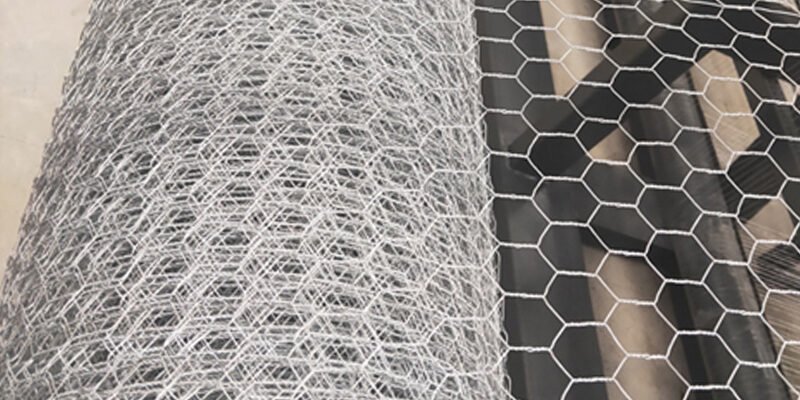

Welded Wire Mesh

Durable mesh with uniform openings for fencing, garden trellises, and small animal enclosures.

View Product -

Razor Wire

High-strength wire suitable for farm, industrial, and security fencing. Provides long-lasting protection.

View Product -

Iron Wire

Versatile wire for construction, binding, and DIY projects. Strong, flexible, and easy to use.

View Product

Post a Comment