The main material types of galvanized chicken wire: The differences are greater than you might think

In different application environments, I will recommend suitable materials based on the customers’ demands. The following are the characteristics of several common materials:

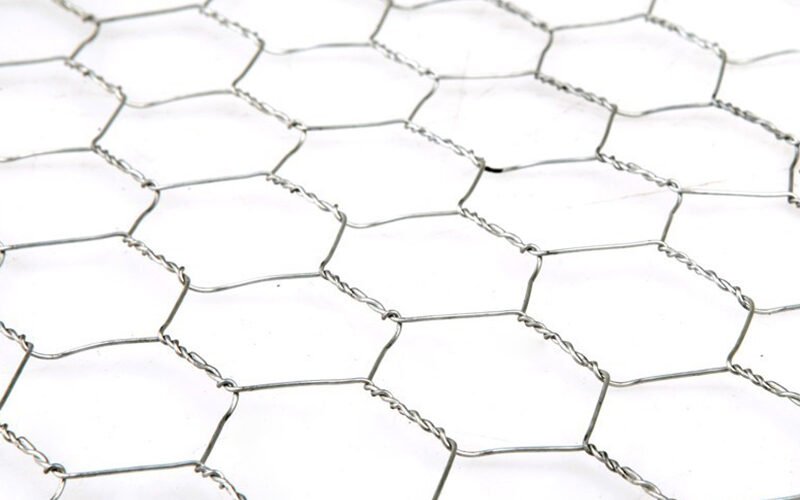

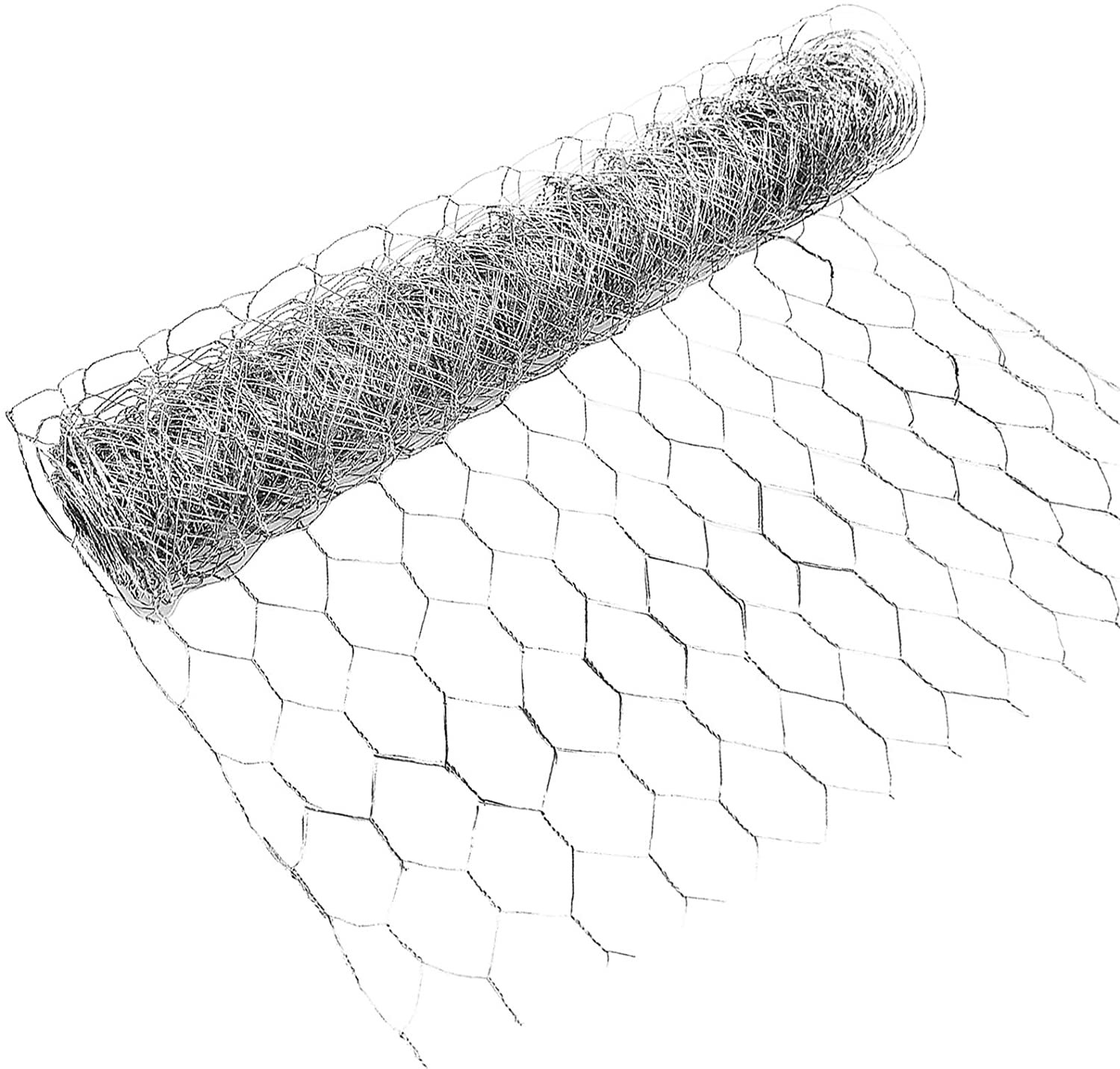

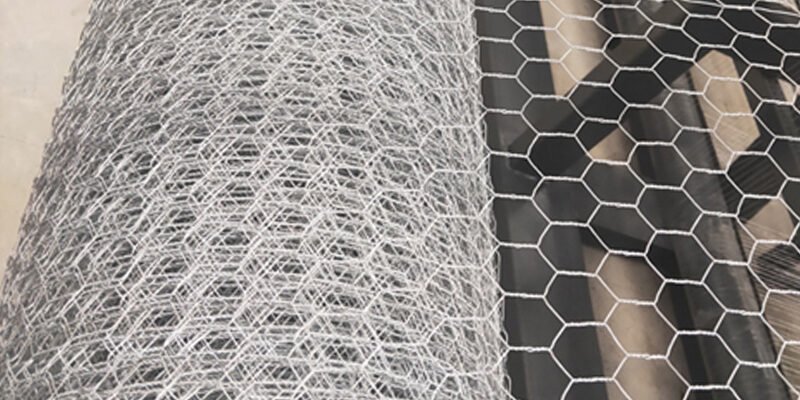

1. Galvanized hexagonal wire mesh

This is the most widely used type. The galvanized coating can protect the iron wire from direct contact with air, thereby enhancing its anti-corrosion performance.

Applicable to

“General breeding”

“Civil Engineering”

Temporary fence

Protective isolation

** Suggestion ** : For long-term outdoor use, it is recommended to choose the “heavy galvanized” specification.

I recommend using PVC galvanized chicken wire in damp, salt spray, acidic or alkaline environments. The plastic outer layer significantly enhances the anti-corrosion property and also provides a more aesthetically pleasing appearance.

Applicable to

Garden fence

Poultry cage

Seaside or wetland environment

** Features ** : Better flexibility and safer hand feel.

3. Stainless steel hexagonal wire mesh

If you are facing extreme environments, such as chemical plants, island aquaculture areas, or environments with continuous water vapor, then I would recommend stainless steel hexagonal mesh without hesitation.

Applicable to

Highly corrosive environment

High-end decoration or construction projects

Food and chemical industries

** Advantage ** : It has an extremely long service life, but the cost is also higher.

How to judge the quality of hexagonal mesh (galvanized chicken wire)? Here are a few key indicators from the factory’s perspective for you

### ✅ 1. Coating thickness **

The thicker the galvanized coating is, the more corrosion-resistant it is.

I suggest choosing a galvanizing weight of ≥ 40g/m² for long-term outdoor use and ≥ 240g/m² for coastal environments.

### ✅ **2. Whether the wire diameter is accurate

Inaccurate wire diameter can cause the entire roll of the net to be uneven and even lead to breakage at local force-bearing points.

### ✅ **3. Whether the weaving process is tight

Poor twisting can cause the mesh to deform and become loose.

In the factory, I often use “tensile testing” to check the overall strength of hexagonal mesh.

### ✅ **4. Firmness of secondary weaving **

High-quality hexagonal mesh usually adopts the “reverse twist weaving” technology to make the structure more stable.

Post a Comment