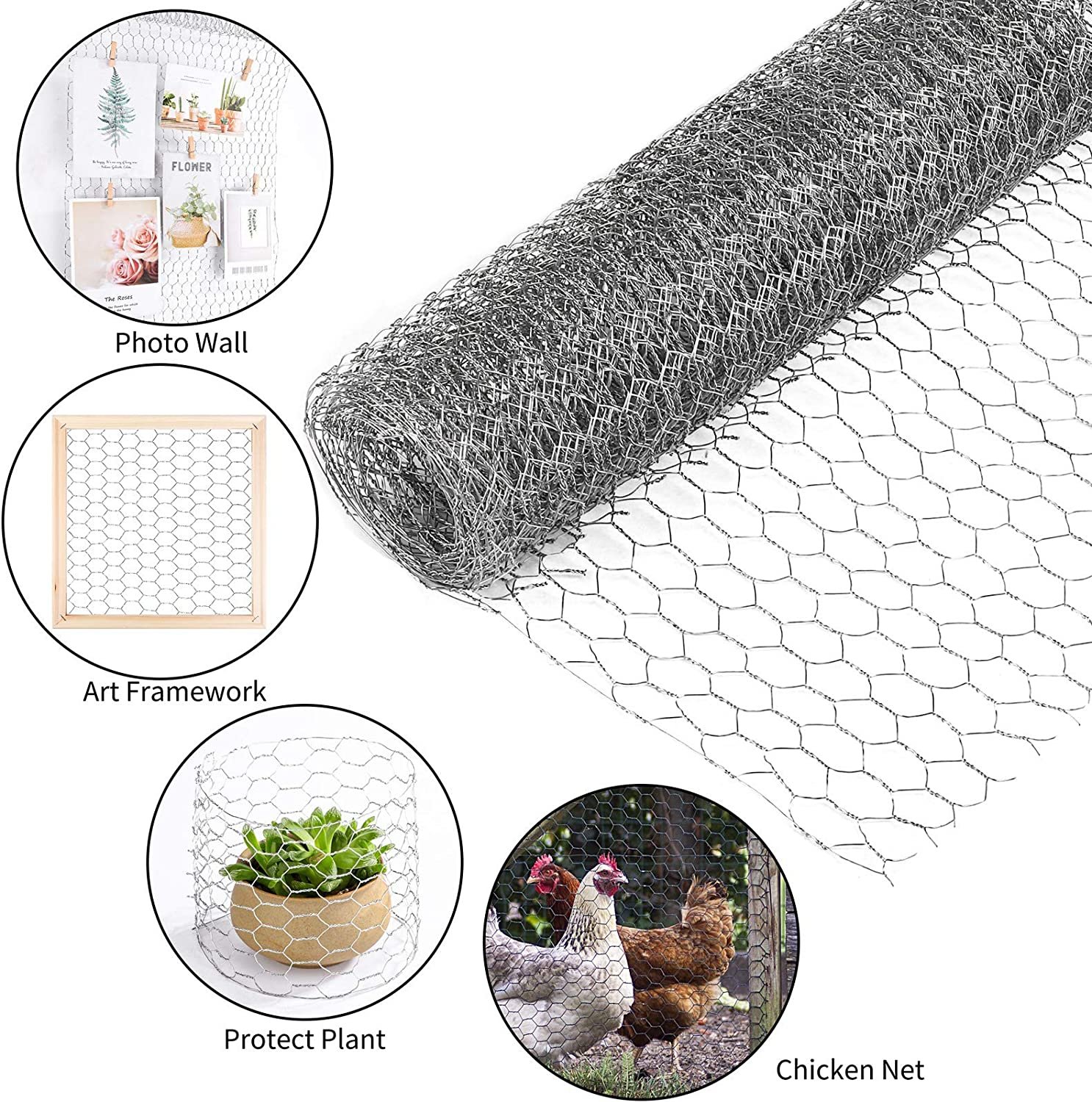

Decorative Wire Mesh for Architectural and Commercial Supply

Decorative wire mesh is increasingly specified in architectural and commercial projects where visual impact, durability, and material consistency are equally important. For wholesalers, metal suppliers, and project contractors, decorative metal screening has become a stable product category serving both interior and exterior design markets.

In B2B procurement, buyers focus less on appearance alone and more on whether a material can be produced, customized, and supplied reliably at scale.

Why Metal Mesh Panels Are Used in Design Projects

Architects and designers choose metal mesh panels not only for aesthetics, but also for their structural and functional performance. Compared with solid panels, open metal screening offers transparency, ventilation, and light control while maintaining strength.

Common reasons design professionals specify architectural wire products include:

-

Clean, modern visual texture

-

Structural stability with open-area design

-

Compatibility with steel, aluminum, or stainless systems

-

Adaptability to different finishes and mounting methods

For suppliers, this makes decorative metal screening suitable for a wide range of project-based orders.

chicken cage portable

Typical Applications in Commercial Markets

Decorative metal mesh panels are widely used in:

-

Building facades and sun-shading systems

-

Interior partitions and feature walls

-

Ceiling panels and railing infill

-

Retail, hospitality, and office environments

Because one mesh structure can serve multiple design purposes, distributors benefit from broader application coverage and higher inquiry diversity.

Material Options and Surface Treatments

From a manufacturing perspective, decorative metal screening can be produced using different materials depending on project requirements:

-

Stainless steel for corrosion resistance and premium appearance

-

Carbon steel for cost-controlled architectural use

-

Aluminum alloys for lightweight structures

Surface finishes such as galvanizing, powder coating, anodizing, or custom coloring help meet both functional and aesthetic expectations.

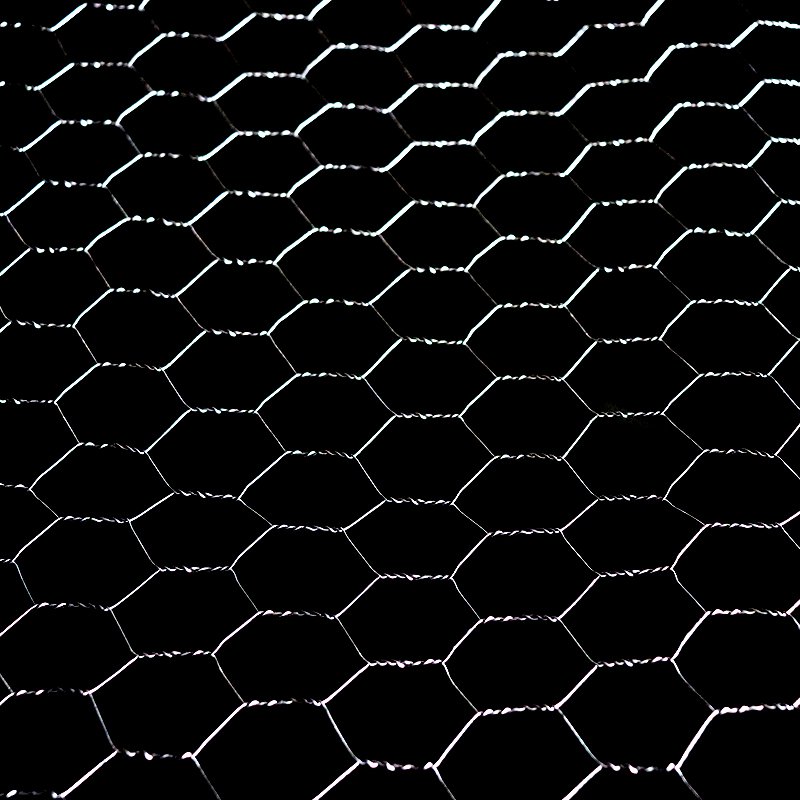

What B2B Buyers Should Evaluate

When sourcing architectural wire mesh panels in bulk, professional buyers typically assess:

-

Wire diameter and mesh pattern consistency

-

Panel size tolerance and flatness

-

Welding or weaving quality

-

Surface finish durability

-

Packaging suitability for transport and installation

Manufacturers with controlled production lines and experienced QC teams are better positioned to support long-term cooperation.

Advantages for Wholesale and Project Supply

Compared with decorative panels made from wood or composite materials, metal mesh panels offer several commercial advantages:

-

Longer service life

-

Lower maintenance requirements

-

Easier customization for projects

-

Better performance in fire and outdoor environments

These characteristics make decorative metal screening a reliable product line for wholesalers and project-focused suppliers.

OEM and Custom Production Capability

Many B2B buyers require project-specific solutions. Professional manufacturers can provide:

-

Custom mesh patterns and opening ratios

-

Tailored panel dimensions

-

Project-matched surface finishes

-

OEM branding and packaging

This flexibility allows distributors to serve architects, contractors, and developers without holding excessive inventory.

Logistics and Export Readiness

Decorative metal mesh panels are typically packed flat or in frames, making them suitable for palletized export. Proper protection during transport ensures surface finishes remain intact upon arrival.

For international buyers, efficient packaging and export experience reduce risk and total procurement cost.

Conclusion

For wholesalers and project buyers seeking a balance of design flexibility and industrial reliability, decorative wire mesh remains a preferred architectural material when sourced directly from an experienced manufacturer. With scalable production, customization capability, and stable quality, it continues to meet the evolving demands of commercial design and construction markets.

👉 If you are sourcing architectural metal mesh for wholesale or project use, contact us to discuss specifications, customization options, and factory-direct pricing.

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment