Chain link fencing systems are widely used in industrial sites, sports facilities, residential boundaries, and infrastructure projects. While fence fabric and posts form the main structure, smaller components such as tie wire play a crucial role in securing the mesh firmly to rails and posts. Choosing the right fastening material ensures long-term durability and structural stability.

What Is Chain Link Fence Tie Wire?

Chain link fence tie wire is a flexible steel wire used to attach chain link mesh to fence posts, top rails, or tension wires. It prevents the mesh from shifting under wind load or physical impact and maintains overall fence alignment.

These fastening wires are typically manufactured from low carbon steel and processed with protective coatings to enhance corrosion resistance.

Common applications include:

-

Industrial perimeter fencing

-

Sports field enclosures

-

Residential chain link fences

-

Highway and public infrastructure fencing

Types of Tie Wire for Chain Link Systems

Different project environments require different surface treatments and strengths.

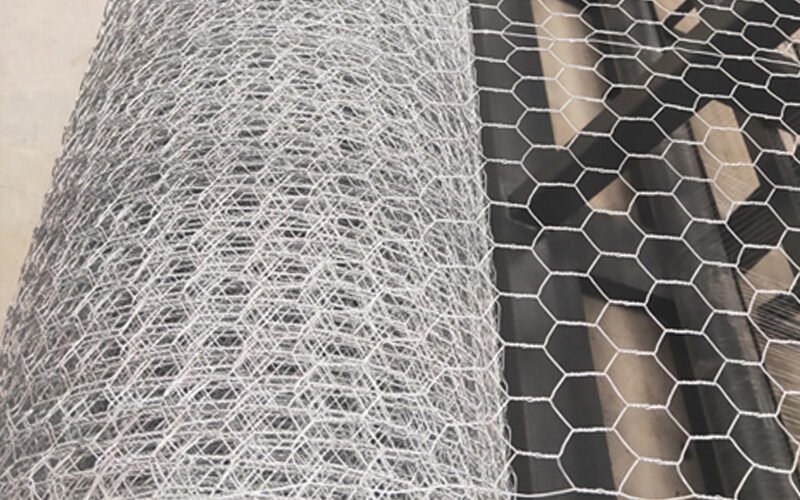

1. Galvanized Tie Wire

Hot-dipped galvanized tie wire offers excellent corrosion resistance. It is suitable for outdoor installations exposed to rain and humidity.

Advantages:

-

Long service life

-

Strong rust resistance

-

Cost-effective for bulk orders

2. PVC Coated Tie Wire

PVC coated options provide additional protection and aesthetic consistency with colored chain link fences.

Advantages:

-

Extra corrosion protection

-

Smooth surface finish

-

Matches black or green coated fencing

3. Stainless Steel Tie Wire

Used in coastal or highly corrosive environments where maximum durability is required.

Advantages:

-

Superior rust resistance

-

Ideal for marine or chemical exposure areas

Key Specifications for Wholesale Buyers

When sourcing in bulk, distributors and contractors typically confirm:

-

Wire diameter (commonly 1.2mm–2.0mm)

-

Coil weight or pre-cut length

-

Surface treatment type

-

Tensile strength

-

Packaging method

Clear technical specifications ensure compatibility with fence mesh and structural components.

Installation and Performance Considerations

Proper fastening is essential for long-term fence stability.

Best practices include:

-

Securing mesh at regular intervals along posts

-

Maintaining consistent tension during installation

-

Avoiding over-tightening to prevent coating damage

-

Matching tie wire material with fence coating type

Using high-quality fastening wire reduces maintenance needs and prevents loosening over time.

Bulk Supply Advantages

For contractors managing large-scale fencing projects, purchasing directly from a manufacturer provides:

-

Competitive factory pricing

-

Stable production capacity

-

Custom packaging options

-

Export-ready pallet loading

-

Consistent quality control

Bulk procurement ensures uniform specifications across the entire project, which is especially important for industrial and infrastructure installations.

Cost Factors in Wholesale Orders

Several factors influence total purchasing cost:

-

Steel raw material prices

-

Zinc coating thickness

-

PVC resin cost

-

Order volume

-

Shipping terms (FOB, CIF, CFR)

Larger volume orders typically reduce per-unit cost and improve freight efficiency through full container loading.

Why Quality Tie Wire Matters

Although tie wire is a small component, it directly affects fence performance. Weak or low-quality fastening materials can result in:

-

Mesh displacement

-

Increased maintenance costs

-

Structural instability

-

Shortened fence lifespan

Investing in high-quality fastening solutions protects the entire fencing system.

Why Choose Our Factory

As a professional welded wire mesh and steel wire manufacturer, we focus on stable production capacity, strict quality control, and long-term cooperation with international distributors.

1. Integrated Production System

From wire drawing to galvanizing and final processing, we control every production step in-house. This ensures consistent wire diameter, coating thickness, and tensile strength across bulk orders.

2. Large-Scale Manufacturing Capacity

Equipped with automated machinery, we maintain stable monthly output to support full container load (FCL) orders and long-term supply contracts.

3. Strict Quality Inspection

Each batch undergoes inspection for:

-

Wire diameter accuracy

-

Zinc coating thickness

-

Surface finish quality

-

Tensile strength compliance

This reduces risk for wholesalers and project contractors.

4. Competitive Factory Pricing

Direct factory supply eliminates unnecessary intermediaries, allowing distributors to secure better margins. FOB, CFR, and CIF terms are available based on customer requirements.

5. Customization & OEM Support

We support:

-

Custom wire diameters and lengths

-

Private label packaging

-

Barcode and logo printing

-

Special export packaging requirements

Ideal for hardware wholesalers and regional distributors building their own brand.

6. Export Experience

With extensive international trade experience, we provide complete export documentation and container loading optimization to ensure smooth customs clearance and cost efficiency.

Post a Comment