Caged Chicken Farms: Wire Mesh Solutions for Efficient Poultry Production

Caged chicken farms are widely adopted in commercial egg production due to their efficiency, scalability, and ease of management. At the core of these systems lies one critical component: wire mesh cage structures, which directly affect farm hygiene, animal safety, and long-term operating costs.

Rather than being just a structural material, welded wire mesh functions as a complete farming solution that supports feeding, ventilation, waste control, and egg collection in modern poultry operations.

Why Wire Mesh Is Essential in Caged Chicken Farms

In cage-based poultry systems, chickens are housed in multi-tier cage units made primarily from welded wire mesh panels. These panels form cage floors, side walls, partitions, and protective barriers.

Compared with sheet metal or plastic components, welded mesh provides:

-

High structural strength under continuous load

-

Open design for airflow and temperature control

-

Smooth surface to reduce injury to chickens

-

Long service life under humid and corrosive farm conditions

Because cages are constantly exposed to moisture, manure, and cleaning chemicals, material quality plays a decisive role in system durability.

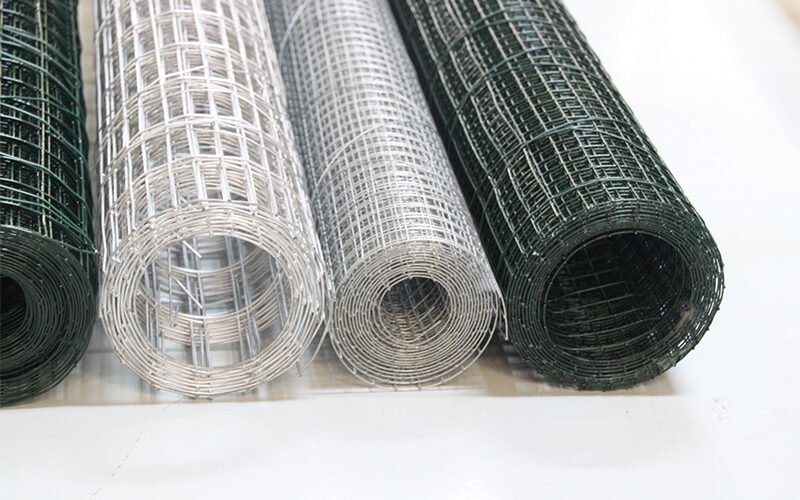

welded wire mesh for rabbit cages

Welded Wire Mesh for Hygiene and Productivity

One of the biggest advantages of welded wire mesh in caged chicken farms is improved hygiene management. The open mesh floor allows waste to fall through efficiently, keeping birds clean and reducing the risk of disease transmission.

Eggs laid by hens roll gently onto collection trays without contact with manure, which helps:

-

Reduce egg contamination

-

Lower breakage rates

-

Improve overall egg quality

This design supports automated feeding and egg collection systems, making welded mesh cages ideal for medium to large-scale poultry farms.

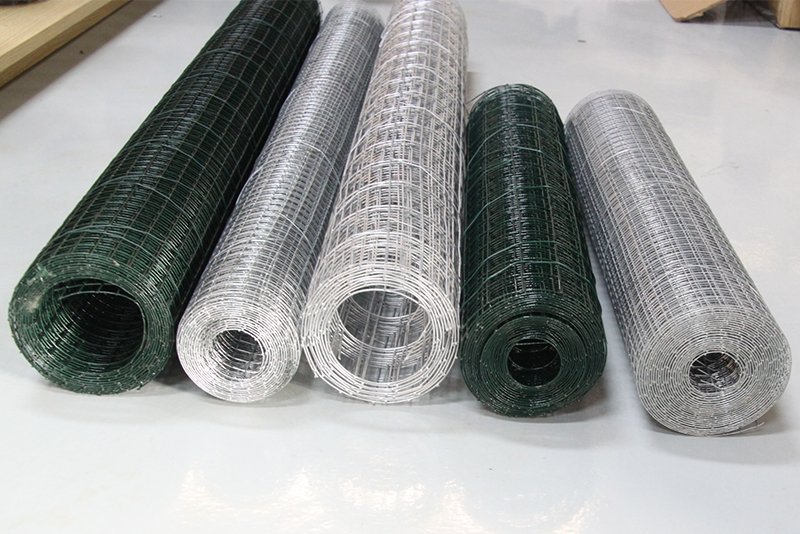

Material Selection for Poultry Cage Systems

For poultry farming applications, wire mesh is typically manufactured from low carbon steel wire with galvanized or hot-dip galvanized surface treatment. These options provide strong corrosion resistance and long-term stability.

Mesh size and wire diameter are customized based on:

-

Cage layer design (single, double, or multi-tier)

-

Farm climate and cleaning frequency

High-quality welded joints ensure the cage maintains its shape and load-bearing capacity throughout years of use.

Factory-Direct Wire Mesh Solutions for Poultry Farms

As a professional wire mesh manufacturer, we supply welded wire mesh specifically designed for caged chicken farm systems. Our products are suitable for cage floors, side panels, partitions, and farm protection fencing.

We support:

-

Custom mesh size and wire diameter

-

Galvanized and heavy zinc coating options

-

Bulk production for farm projects

-

Stable quality for export markets

By sourcing wire mesh directly from a factory, poultry farm investors and equipment suppliers can better control costs while ensuring consistent material performance.

Conclusion: A Practical Solution for Modern Poultry Farming

Caged chicken farms continue to rely on welded wire mesh as a core material for efficient, hygienic, and scalable egg production. When properly designed and manufactured, wire mesh cage systems reduce maintenance costs, improve productivity, and support long-term farm operation.

For poultry projects focused on durability and efficiency, choosing the right wire mesh solution is a critical step toward sustainable farm success.

Get Wire Mesh Solutions for Caged Chicken Farms

Looking for durable welded wire mesh for poultry cage systems? We supply factory-direct wire mesh solutions with stable quality and custom specifications for bulk orders.

📲 WhatsApp: +86 18830227875

Contact us now to get technical details, samples, or a fast quotation.

Factory direct | Bulk supply | Export ready

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment