When planning perimeter security for farmland, ranches, highways, or industrial sites, cost is often the first concern for contractors and distributors. Material selection, coating type, wire gauge, and installation method all influence the final budget. Buyers comparing international suppliers are not just looking for a low number—they want stable quality, export-grade packaging, and predictable delivery timelines. Understanding how pricing is structured helps procurement managers avoid hidden costs and choose the right fencing solution for long-term performance.

What Determines the Cost of Barbed Wire Fencing?

Several core factors influence the overall expense of this fencing material. Whether you are a wholesaler, agricultural supplier, or project contractor, knowing these variables allows you to estimate accurately and negotiate effectively.

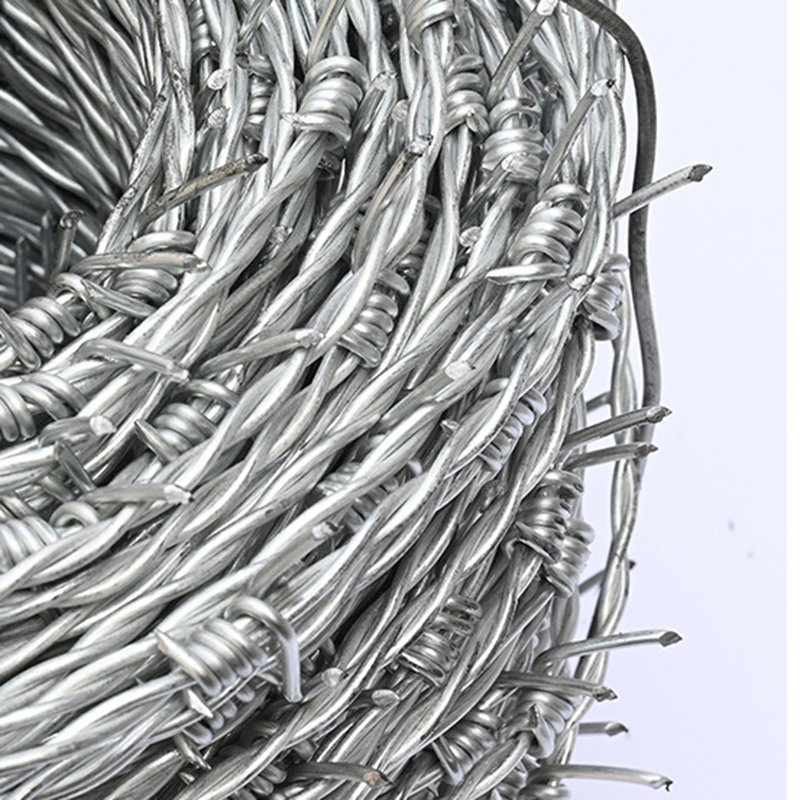

1. Wire Diameter (Gauge)

Thicker wire requires more raw steel, which increases material cost. Common gauges range from 12 to 15 gauge. Heavier gauges provide stronger tension resistance and longer service life, making them ideal for livestock control and security perimeters.

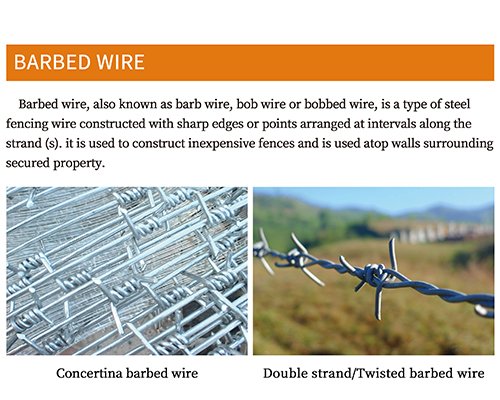

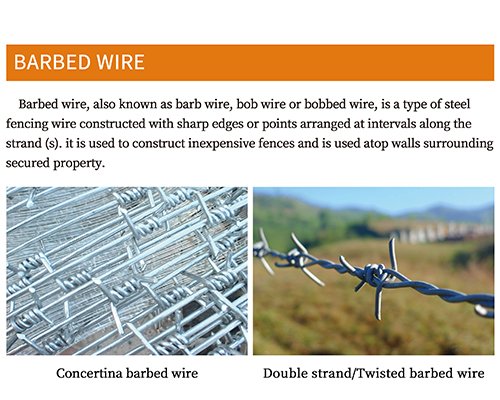

2. Barb Spacing and Twist Type

Standard barbed wire usually comes in 2-point or 4-point designs. Closer barb spacing increases production time and steel usage. Reverse-twist and traditional twist types may also vary slightly in price depending on machinery efficiency and labor input.

3. Surface Treatment

Surface coating significantly impacts durability and price. Options typically include:

-

Electro-galvanized

-

Hot-dipped galvanized

-

PVC coated

Hot-dipped galvanizing provides thicker zinc coating and longer corrosion resistance, especially in coastal or high-humidity regions. Naturally, heavier zinc coating means higher raw material and processing cost.

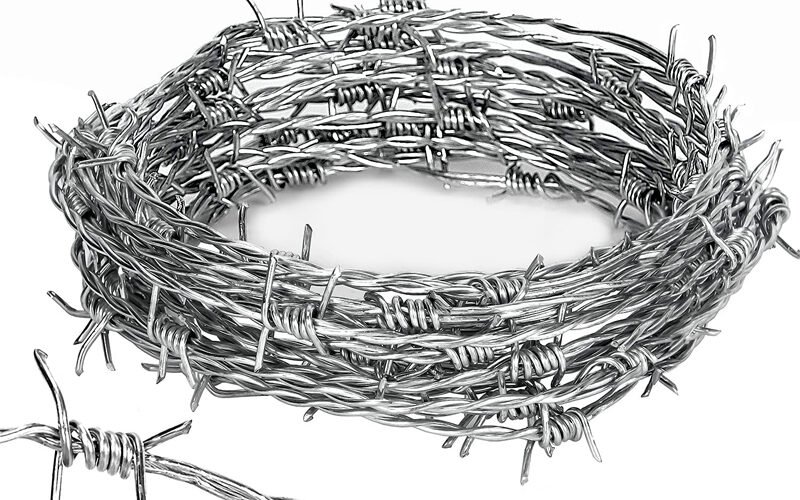

4. Coil Weight and Packaging

Standard coil weights include 25kg, 50kg, and customized bulk coils. Export buyers often request palletized packaging or woven bag wrapping to prevent transport damage. These packaging upgrades slightly increase total export pricing.

Understanding Barbed Wire Fence Price Per Foot in Bulk Orders

For large-scale procurement, buyers frequently evaluate the barbed wire fence price per foot to compare suppliers across regions. When calculating per-foot cost, manufacturers typically base pricing on raw material steel wire cost, zinc price fluctuations, labor, and factory overhead.

China-based manufacturers often offer competitive FOB rates due to large-scale production lines and automated twisting machines. For B2B buyers, bulk purchasing dramatically lowers the per-unit fencing cost because fixed expenses are distributed across higher volumes.

It is important to confirm:

These factors directly affect the final export quotation.

Comparing Cost Per Linear Foot Across Coating Types

Instead of focusing only on initial purchase price, professional buyers evaluate lifecycle value. A cheaper electro-galvanized option may require replacement sooner in harsh climates, while hot-dipped galvanized fencing lasts significantly longer.

For agricultural distributors in Africa, South America, and Southeast Asia, long-term corrosion resistance is critical. Projects near coastal areas typically specify higher zinc coating levels (200g/m² or above). While this raises the initial cost per linear foot, it reduces maintenance and replacement expenses over time.

PVC-coated options add an extra protective layer and aesthetic appearance, often used in residential or light commercial boundaries. However, they are less common for large livestock fencing due to higher material costs.

Raw Material Market Fluctuation and Its Impact

Steel wire pricing is closely tied to global carbon steel market trends. When raw steel prices rise, fencing material pricing adjusts accordingly. Zinc prices also influence galvanizing costs.

Professional importers track:

Timing bulk purchases strategically can reduce procurement cost significantly. Many wholesale buyers negotiate quarterly or semi-annual contracts to lock in favorable pricing.

Installation Costs vs Material Costs

For many projects, installation accounts for a large portion of total fencing expenditure. Posts, tensioning tools, labor, and ground preparation must all be considered.

Common installation components include:

Even if the material rate is competitive, improper installation may lead to sagging or reduced lifespan. Professional contractors often prefer higher tensile strength fencing to reduce long-term repair costs.

Barbed Wire Fence Price Per Foot for Large Projects

When calculating the barbed wire fence price per foot for agricultural estates, ranch developments, or infrastructure projects, volume plays a crucial role. Orders above one full container load (FCL) typically receive factory-level pricing.

For example:

-

20FT container loading capacity depends on coil weight

-

Mixed specifications can affect container optimization

-

OEM labeling and customized barbed spacing may add minor tooling fees

Distributors seeking long-term partnerships often negotiate annual supply agreements, ensuring consistent production scheduling and priority shipping slots.

Export Considerations for International Buyers

International B2B buyers should confirm the following before placing bulk orders:

1. HS Code and Import Duties

Different countries classify fencing materials under various tariff codes. Import duty percentage directly affects landed cost.

2. Certification Requirements

Some regions require mill test certificates, SGS inspection, or quality compliance documents.

3. Shipping Terms

FOB, CFR, or CIF pricing structures change the total delivered cost. FOB is commonly preferred by experienced importers managing their own freight forwarders.

4. Payment Terms

Standard terms include T/T 30% deposit + 70% before shipment. Long-term clients may negotiate more flexible arrangements.

How Manufacturers Calculate Wholesale Fencing Cost

Professional factories calculate export quotations based on:

-

Raw steel rod cost

-

Drawing and twisting processing cost

-

Zinc coating thickness

-

Labor and electricity consumption

-

Packaging materials

-

Inland transportation to port

-

Profit margin

Automated production lines reduce labor intensity and improve consistency, which benefits bulk buyers seeking stable long-term supply.

Factories with integrated wire drawing and galvanizing facilities can control quality and reduce outsourcing costs, leading to more competitive offers for distributors.

Choosing the Right Supplier

When sourcing fencing materials internationally, price alone should not determine your decision. Evaluate:

Request product samples before confirming large-volume orders. Reliable manufacturers provide clear technical specifications and transparent quotations.

Long-Term Value Over Lowest Initial Cost

While buyers often focus on immediate budget considerations, professional procurement teams understand that durability, corrosion resistance, and tensile strength influence total ownership cost.

Higher-quality fencing may reduce:

-

Maintenance frequency

-

Replacement cycles

-

Livestock escape risk

-

Security breaches

Over a 5–10 year period, investing in stronger galvanized fencing typically proves more economical than repeatedly replacing low-grade material.

Conclusion

Accurately estimating fencing expenses requires understanding raw material trends, coating differences, installation factors, and supplier reliability. For wholesalers, agricultural distributors, and infrastructure contractors, evaluating cost per linear foot in combination with long-term durability ensures profitable and sustainable procurement decisions.

Working directly with experienced manufacturers allows bulk buyers to secure competitive export pricing, stable production schedules, and customized specifications tailored to regional requirements. By analyzing coating thickness, wire gauge, packaging standards, and shipping terms, international buyers can confidently manage large-scale fencing projects while maintaining strong margins in their local markets.

Related Products

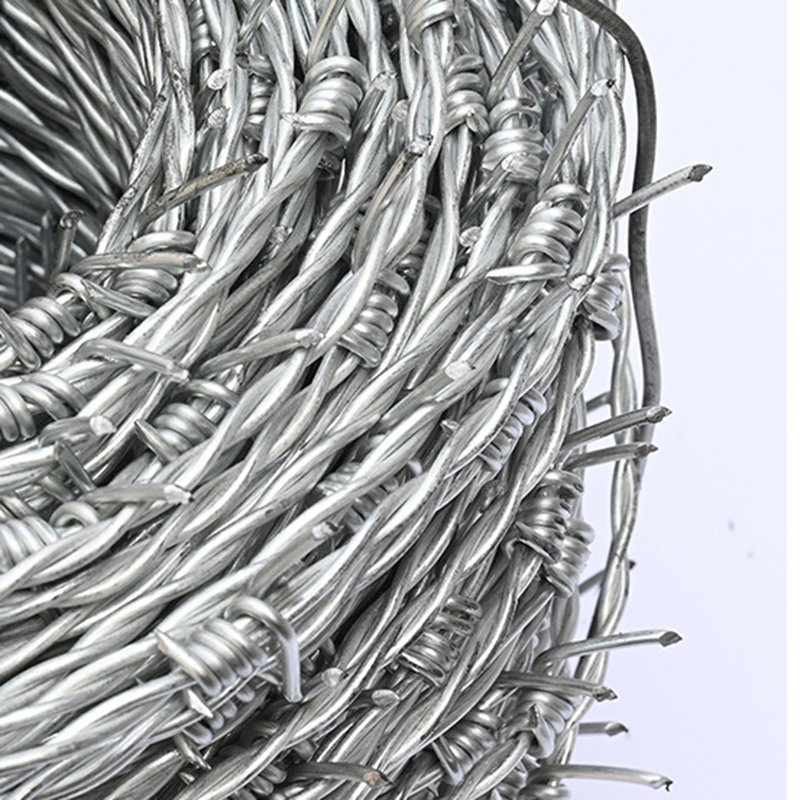

Galvanized Barbed Wire Rolls

Durable hot-dipped galvanized or PVC coated options for agricultural and security fencing projects. Ideal for bulk supply.

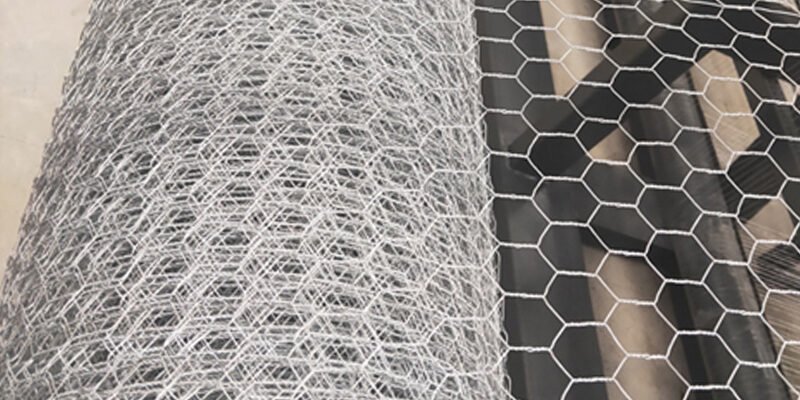

Welded Wire Mesh Panels

Strong and easy-to-install fence panels for industrial, warehouse, and perimeter protection applications.

Black Annealed Binding Wire

Flexible tying wire for construction, fencing installation, and general binding use.

Galvanized Steel Wire

High tensile strength wire for tension lines and long-span fence reinforcement.

Contact us for wholesale pricing and full container load supply options.

Post a Comment