Advanced Steel Woven Wire Mesh Design: Engineering Precision from Wire to Structure

Advanced steel woven wire mesh design is not simply about weaving metal wires together. It is a result of material science, mechanical engineering, and production experience working in harmony. From wire selection to weaving accuracy and final performance control, every step influences strength, durability, and application suitability. In industrial, architectural, and filtration projects, design-driven woven mesh plays a critical role in long-term reliability.

1. Material Selection: The Foundation of Woven Mesh Performance

The design process starts with steel wire selection. Carbon steel, galvanized steel, and stainless steel are the most commonly used materials, each chosen based on environmental conditions and functional demands.

High-quality wire must meet strict requirements for diameter tolerance, tensile strength, and surface consistency. Even slight deviations can affect mesh opening accuracy and structural balance. For advanced applications, stainless steel grades such as 304 or 316 are often preferred due to their corrosion resistance, temperature stability, and clean surface finish.

Material preparation also includes surface treatment before weaving. Proper cleaning and annealing improve wire flexibility, reduce internal stress, and ensure smooth interlocking during weaving.

2. Precision Weaving Techniques and Structural Control

Advanced woven wire mesh relies on controlled weaving methods such as plain weave, twill weave, and Dutch weave. Each structure serves a different functional purpose:

-

Plain weave offers uniform openings and balanced strength

-

Twill weave supports heavier wire diameters with enhanced load capacity

-

Dutch weave provides high-density filtration with fine particle control

Modern weaving equipment allows precise control of wire tension, alignment, and intersection consistency. This ensures uniform mesh apertures across the entire roll or sheet, which is essential for filtration efficiency, airflow regulation, and visual uniformity in architectural use.

Design engineers also consider edge stability and mesh flatness, especially for large-format panels. These factors directly impact installation quality and long-term performance.

3. Strength, Flexibility, and Functional Design Balance

One of the main advantages of woven mesh design is its ability to balance strength with flexibility. Unlike rigid structures, woven mesh can absorb impact, vibration, and thermal expansion without cracking or breaking.

Advanced designs optimize wire diameter and weave density to achieve specific performance goals. For example, higher tensile strength supports industrial screening, while flexible structures suit architectural facades or protective enclosures.

Surface smoothness is another design focus. Clean intersections and burr-free edges improve safety during handling and installation, particularly in food processing, pharmaceutical, and clean-room environments.

4. Woven Mesh vs Welded Mesh: Structural Design Comparison

Understanding the difference between woven mesh and welded mesh is essential when selecting the right structure.

Woven wire mesh is created by interlacing wires without welding. This structure allows slight movement between wires, providing flexibility, shock resistance, and adaptability. It performs well under dynamic loads and is ideal for filtration, vibration screening, and decorative applications.

Welded wire mesh, by contrast, relies on rigid weld points at each intersection. It offers higher dimensional stability and is suitable for fencing, cages, and reinforcement where fixed spacing is required. However, welded joints can become stress points under repeated impact or corrosion if surface treatment is insufficient.

From a design perspective, woven mesh emphasizes adaptability and precision, while welded mesh prioritizes rigidity and structural simplicity. Choosing between them depends on functional requirements rather than appearance alone.

5. Design-Driven Applications Across Industries

Advanced steel woven wire mesh design supports a wide range of applications:

-

Industrial filtration and separation systems

-

Chemical processing and oil refining

-

Architectural facades, sunshades, and interior panels

-

Security screens and protective guards

-

Agricultural sieving and processing

Each application demands tailored design parameters, including mesh opening, wire diameter, and surface finish. Custom engineering ensures the mesh performs reliably under specific environmental and mechanical conditions.

6. Manufacturing Control and Quality Assurance

Design excellence must be supported by strict quality control. Advanced manufacturers apply continuous inspection during weaving, followed by dimensional checks, tensile testing, and surface evaluation.

Consistent production ensures batch-to-batch uniformity, which is critical for large-scale projects and export markets. Packaging design also plays a role, preventing deformation during transportation and maintaining mesh integrity upon delivery.

Conclusion: Design as the Core Value of Woven Wire Mesh

Advanced steel woven wire mesh design transforms raw steel wire into a high-performance engineered material. Through careful material selection, precise weaving, and application-driven structure planning, woven mesh delivers reliability that extends far beyond basic fencing or screening. For projects that demand accuracy, durability, and long-term value, design-focused woven wire mesh remains a superior solution.

Request a Quote or Custom Solution

If you are sourcing fencing for agricultural, commercial, or infrastructure projects, our team can help you select the right specification and provide fast technical support.

📲 Contact us on WhatsApp: +86 18830227875

Get factory pricing, export-ready products, and reliable delivery from a trusted wire mesh supplier.

Our Factory Advantages

With years of experience in wire and mesh manufacturing, TS Wire Mesh is a professional factory specializing in metal wire, wire mesh fencing, and custom steel products for global markets. We focus on stable quality, factory-direct pricing, and long-term cooperation with wholesalers, distributors, and project buyers worldwide.

1. Factory-Direct Manufacturing, Competitive Pricing

As a source manufacturer, we control the entire production process—from raw material selection to wire drawing, welding, weaving, surface treatment, and packing. This direct factory operation eliminates unnecessary middle costs, allowing us to offer competitive ex-factory prices while maintaining consistent quality. OEM and bulk orders are always welcome.

2. Strict Raw Material & Quality Control

We use carefully selected low-carbon steel wire, high-carbon steel wire, galvanized steel wire, and stainless steel wire sourced from qualified steel mills. Every production stage follows internal quality inspection standards, including wire diameter tolerance, zinc coating thickness, weld strength, and tensile performance. Export-grade quality control ensures stable performance in different climates and applications.

3. Wide Product Range, One-Stop Supply

Our factory produces a complete range of wire and mesh products, including:

-

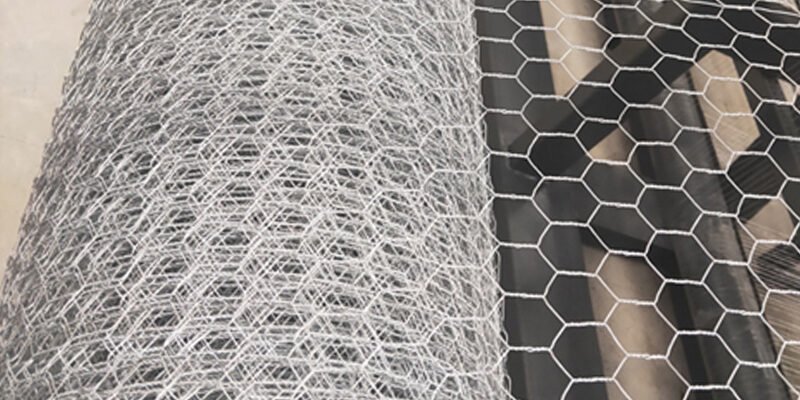

Hexagonal wire mesh (chicken wire)

-

Field fence & livestock fencing

-

Galvanized / PVC coated iron wire

-

Steel cable wire rope

This one-stop supply capability helps buyers reduce sourcing time, logistics costs, and communication risks.

4. Customization & OEM Capability

We support custom specifications such as wire diameter, mesh opening, panel size, roll length, surface finish, and packaging design. Our technical team works closely with customers to meet market standards in North America, Europe, Africa, and the Middle East. Private label and OEM packaging are fully supported.

5. Export Experience & Reliable Delivery

With rich export experience, we are familiar with international trade processes, packaging requirements, and container loading solutions. Stable production capacity and efficient scheduling allow us to ensure on-time delivery for both small trial orders and large-volume shipments.

6. Professional Service & Long-Term Partnership

Our team understands B2B buyers’ real needs—quality stability, clear communication, and after-sales responsibility. We aim to build long-term partnerships, not just one-time transactions, by providing honest quotations, fast responses, and continuous support.

Post a Comment