Stainless Steel Woven Wire Mesh for Industrial and Commercial Applications

Stainless steel woven wire mesh is widely used in industrial filtration, screening, architectural applications, and equipment protection where corrosion resistance, dimensional accuracy, and long service life are required. For B2B buyers, this product is valued not only for its material properties, but also for manufacturing precision and specification consistency.

This article is prepared for importers, distributors, equipment manufacturers, and project contractors seeking reliable woven mesh solutions from experienced manufacturers.

Core product types and applications

1. Welded Wire Mesh for Chick Cages

-

Stable Structure: Rigid mesh panels with welded intersections

-

Use Case: Ideal for cage walls, floors, and partitions in poultry housing

-

Benefit: Maintains shape under load and simplifies installation

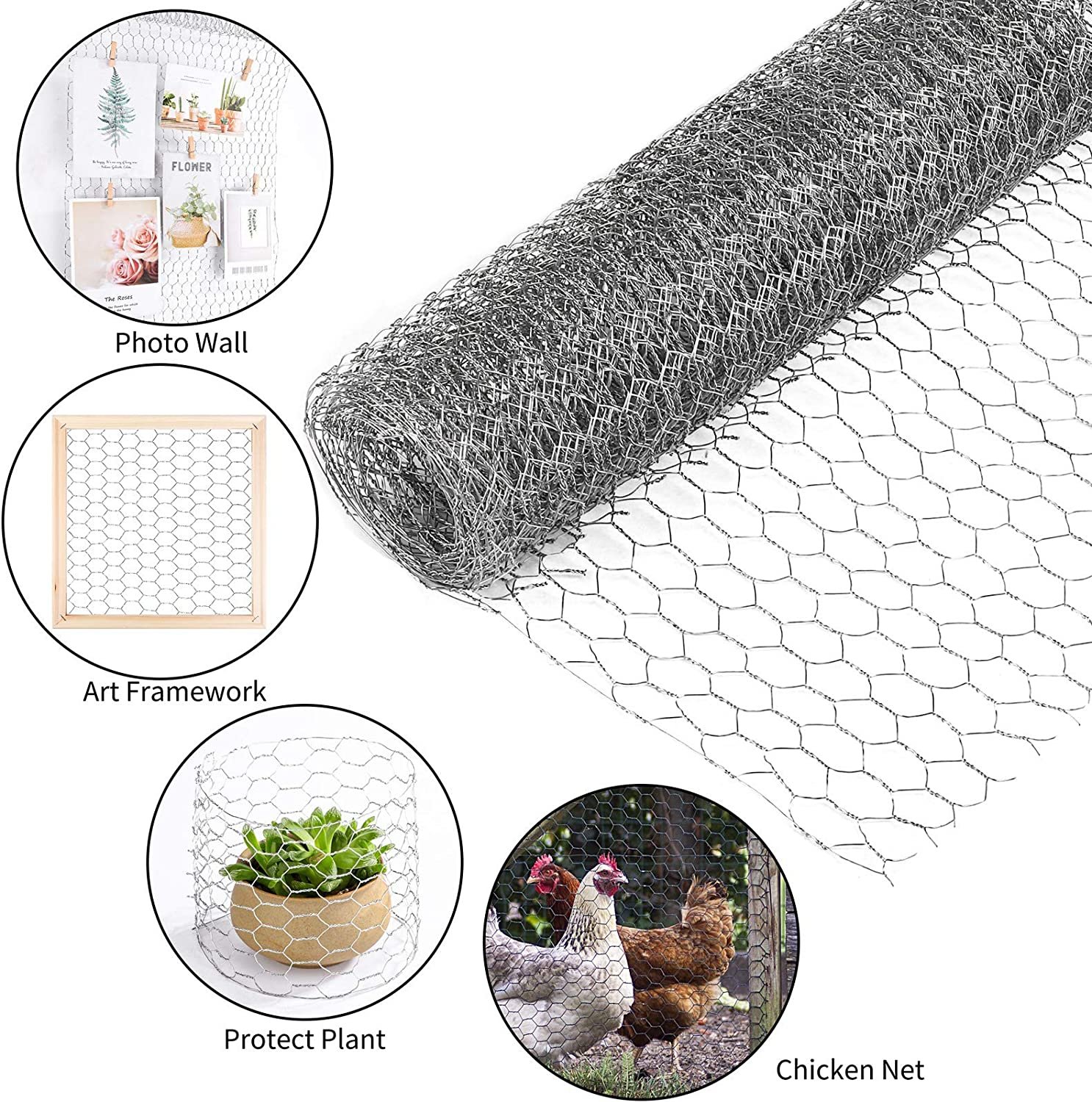

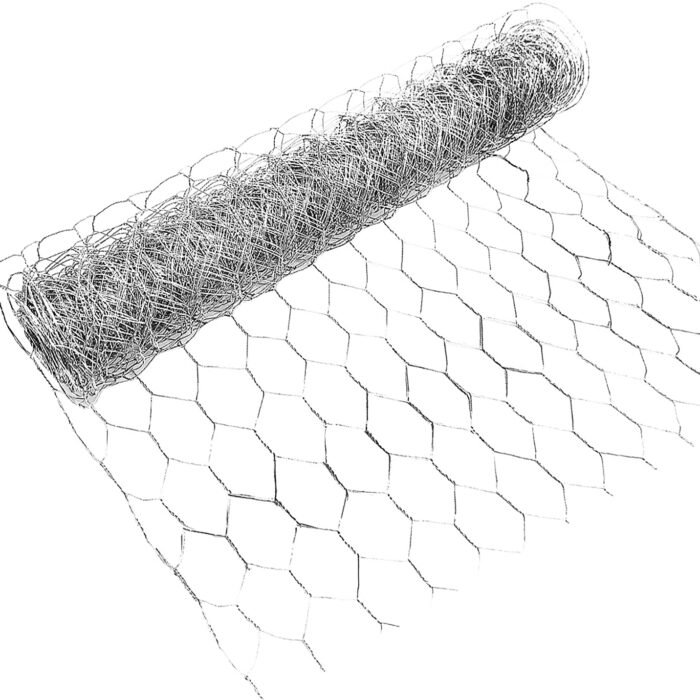

2. Hexagonal Wire Mesh (Poultry Netting)

-

Flexible Mesh: Woven into hexagon openings

-

Use Case: Best for lightweight enclosures and curved layouts

-

Benefit: Adapts to uneven terrain and minimizes injury risk

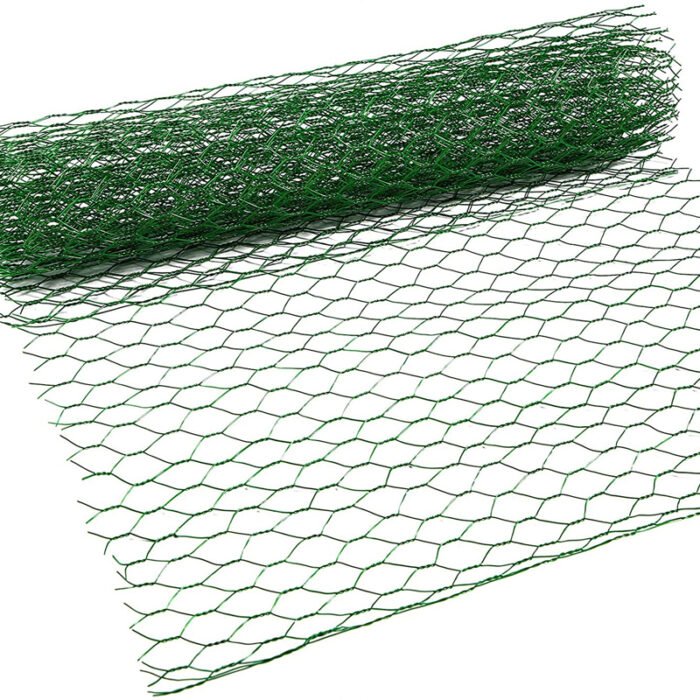

3. PVC-Coated and Galvanized Options

-

Corrosion Protection: Extends outdoor performance

-

Use Case: Suitable for humid and wash-down environments

-

Benefit: Reduces long-term maintenance

-

What Is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is produced by interweaving stainless steel wires in a regular pattern to form uniform openings. Unlike welded mesh, woven mesh maintains flexibility while offering excellent strength and stability.

Key characteristics include:

-

High resistance to corrosion and oxidation

-

Uniform aperture and smooth surface

-

Good tensile strength and flexibility

-

Suitability for precision industrial applications

It is commonly manufactured using stainless steel grades such as 304, 316, or 316L, depending on environmental and chemical requirements.

Typical Industrial Applications

Stainless steel woven mesh is widely specified in:

-

Industrial filtration and separation systems

-

Mining and quarry screening

-

Chemical and pharmaceutical processing

-

Food processing and hygiene-sensitive environments

-

Architectural facades and decorative panels

In many systems, woven mesh is used together with welded wire mesh fence or perforated metal to form multi-layer screening structures.

-

-

Weaving Types and Mesh Structures

Different weaving methods affect performance and application suitability.

Plain Weave

The most common structure, offering balanced strength and uniform openings.

Twill Weave

Used for heavier wire diameters or finer mesh counts, improving structural stability.

Dutch Weave

Designed for filtration applications where precise particle retention is required.

Selecting the correct weave type is essential for achieving expected performance in industrial systems.

Material Grades and Performance Differences

Stainless Steel 304

Offers good corrosion resistance and cost efficiency, widely used in general industrial environments.

Stainless Steel 316 / 316L

Provides enhanced resistance to chemicals and marine environments, suitable for demanding applications.

For buyers, confirming material grade, wire diameter tolerance, and mesh count is critical before bulk procurement.

Comparison with Other Wire Mesh Products

From a B2B sourcing perspective:

-

Compared with welded wire mesh fence, woven mesh offers higher precision

-

Compared with Hexagonal Wire Mesh, it provides greater uniformity

-

Compared with carbon steel mesh, it offers superior corrosion resistance

In industrial projects, woven mesh is often paired with wire rope, iron wire, or frames for structural support.

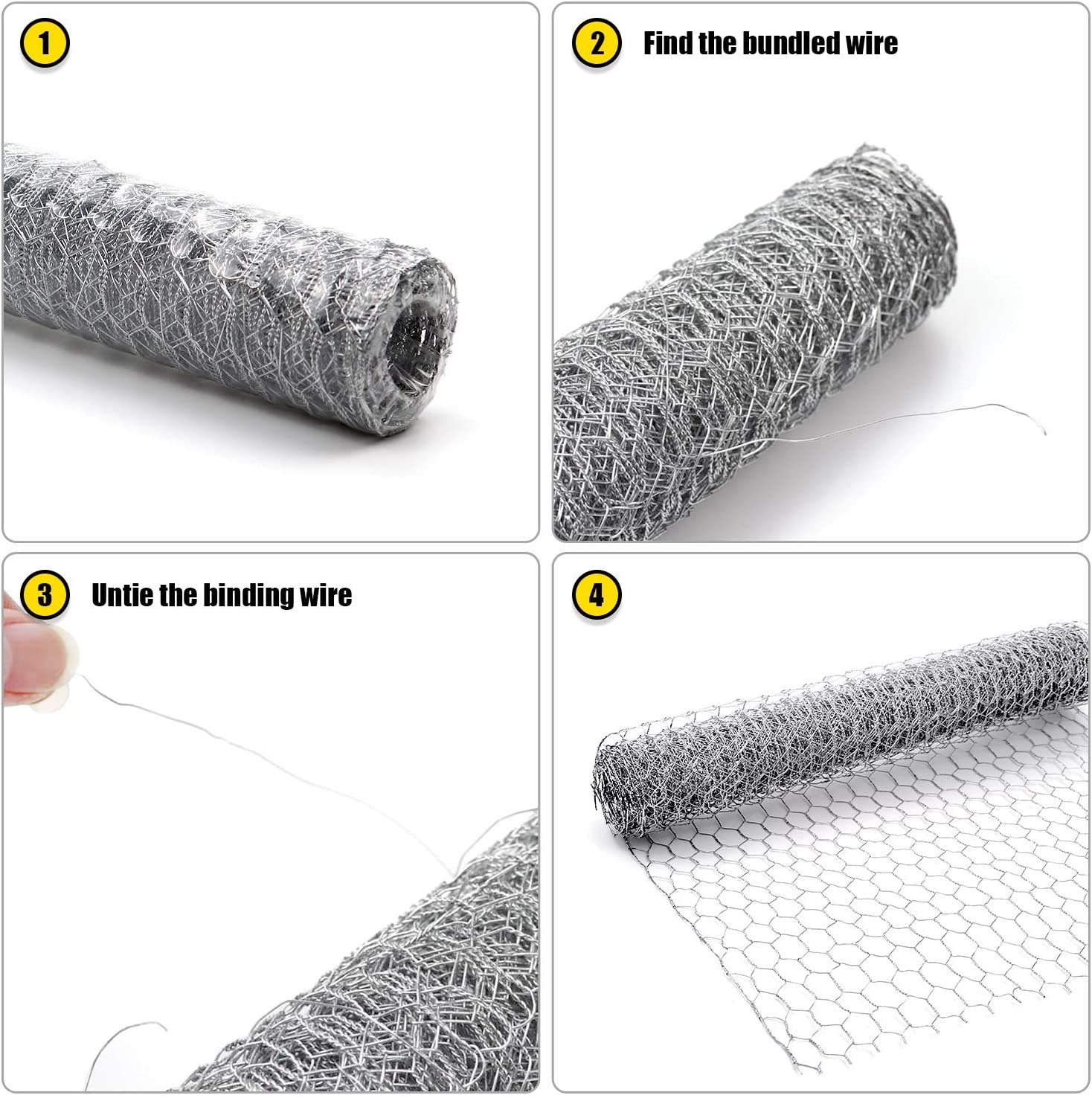

Installation and Processing Considerations

Stainless steel woven mesh is commonly supplied in rolls, sheets, or cut-to-size panels. Installation methods include:

-

Framing with stainless steel profiles

-

Clamping into filtration systems

-

Fixing with fasteners or iron nail alternatives made of stainless steel

Ease of processing makes it suitable for both factory assembly and on-site installation.

Cost Factors for B2B Buyers

Pricing of stainless steel woven wire mesh depends on:

-

Stainless steel grade

-

Wire diameter and mesh count

-

Weaving method

-

Sheet or roll size

-

Order volume and packaging

Factory-direct sourcing allows buyers to control specifications while optimizing total procurement cost.

Bulk Supply and Custom Manufacturing

Professional manufacturers support:

-

Customized mesh count and wire diameter

-

OEM labeling and private packaging

-

Stable supply for long-term contracts

-

Export-standard packaging

This is especially important for distributors and equipment manufacturers serving multiple industries.

Stainless Steel Woven Wire Mesh in Scalable Projects

For industrial systems requiring repeatability and precision, stainless steel woven wire mesh provides reliable performance across large production batches. Working with an experienced manufacturer ensures consistency in material quality and weaving accuracy.

-

B2B Conversion Section – Factory Supply & Cooperation (≈800 chars)

Looking for a reliable wire mesh solution for cage-free poultry projects?

We are a direct manufacturer specializing in hexagonal wire mesh and welded wire mesh for agricultural and livestock applications.

Our factory offers:

-

Multiple hexagonal mesh types for poultry housing and outdoor runs

-

Stable galvanized and PVC-coated production lines

-

Consistent quality for bulk and project orders

-

OEM specifications tailored to regional farm standards

With years of export experience, we support wholesalers, farm contractors, and poultry equipment suppliers with efficient production and professional technical guidance.

📲 WhatsApp: +86 18830227875

Contact us today to discuss your poultry project requirements and receive a fast quotation.

Product Information Table (Hexagonal Chicken Wire)

| Attribute | Description |

| Material | Galvanized iron wire with PVC coating |

| Weaving Type | Hexagonal twisted wire mesh |

| Surface Treatment | Hot-dip galvanized + PVC coated |

| Wire Diameter | 0.6–1.2 mm (custom options available) |

| Mesh Opening | Hexagonal mesh, commonly 1″, 1.5″, 2″ |

| Roll Size | Customized width and length available |

| Color Options | Green, black, or customized |

| Main Applications | Poultry fencing, garden protection, plant support, animal enclosures |

FAQ – Frequently Asked Questions (Hexagonal Wire Mesh)

Q1: What is the main difference between hexagonal chicken wire and welded wire mesh?

Hexagonal chicken wire is woven with twisted strands, making it more flexible and easier to bend, while welded mesh is rigid. Chicken wire is better for lightweight fencing and plant support.

Q2: Is PVC-coated chicken wire suitable for outdoor use?

Yes. The PVC coating protects the galvanized wire from moisture, soil contact, and UV exposure, significantly extending its service life outdoors.

Q3: Can hexagonal chicken wire be used as a trellis for plants?

Absolutely. Its flexible structure makes it ideal for climbing plants, flowers, and vegetable vines while allowing natural growth and airflow.

Q4: Is this type of chicken wire safe for animals and plants?

Yes. The twisted hexagonal structure and smooth coating reduce sharp edges, making it safer for poultry, pets, and garden plants.

Q5: Can I cut and connect multiple rolls together?

Yes. Chicken wire can be easily cut with standard wire cutters, and multiple rolls can be joined to cover larger areas without waste.