Galvanized Steel Guy Wire: A Reliable Solution for Structural Support

Galvanized steel guy wire is an essential component in modern infrastructure and utility projects. It is widely used to stabilize poles, towers, masts, and other vertical structures by providing reliable tension support. Thanks to its high tensile strength and excellent corrosion resistance, galvanized steel guy wire has become a preferred choice for long-term outdoor applications in power, telecom, and industrial sectors.

Unlike fencing or enclosure materials, guy wire is designed to bear continuous loads and resist environmental forces such as wind, vibration, and structural movement. Choosing the right type of guy wire is critical to ensuring the safety and stability of the entire support system.

What Is Galvanized Steel Guy Wire?

Galvanized steel guy wire is manufactured from high-quality carbon steel wire rod and coated with zinc to protect against corrosion. The galvanizing process significantly extends the service life of the wire, making it suitable for harsh outdoor environments, including humid, rainy, or coastal regions.

There are two common galvanizing methods:

-

Hot-dip galvanizing, which provides a thicker zinc coating and superior corrosion resistance

-

Electro galvanizing, which offers a smoother surface and uniform appearance for moderate environments

Hot-dip galvanized steel guy wire is generally recommended for infrastructure and utility projects that require long-term durability and minimal maintenance.

Key Applications in Infrastructure Projects

Galvanized steel guy wire plays a vital role in a wide range of applications, including:

-

Power transmission and distribution poles

-

Telecom and communication towers

-

Radio and antenna masts

-

Street lighting and traffic signage poles

-

Temporary or permanent structural bracing systems

In these applications, guy wire works together with anchors, clamps, and turnbuckles to maintain proper tension and structural alignment over time.

Advantages of Galvanized Steel Guy Wire

One of the main advantages of galvanized steel guy wire is its high tensile strength, which allows it to handle continuous loads without excessive elongation. This makes it ideal for stabilizing tall structures exposed to wind and vibration.

Additional benefits include:

-

Strong corrosion resistance for outdoor use

-

Consistent mechanical performance

-

Compatibility with standard anchoring hardware

-

Long service life and low maintenance cost

These advantages make galvanized steel guy wire a cost-effective and reliable solution for large-scale projects.

Comparison with Other Wire and Wire Mesh Products

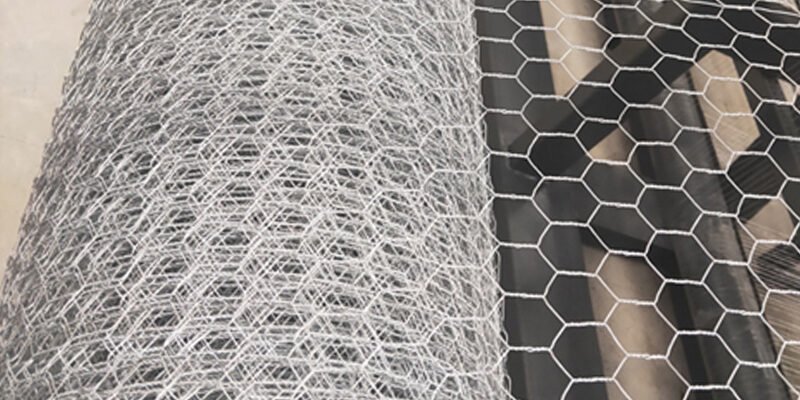

Although galvanized steel guy wire is made from steel wire, its function is very different from traditional wire mesh products.

Compared with welded wire mesh, which is mainly used for fencing, enclosures, and security barriers, guy wire is a load-bearing component designed for tension support rather than surface protection.

Compared with galvanized iron wire, which is commonly used for binding, tying, or general-purpose applications, guy wire is manufactured under stricter tensile strength requirements and quality control standards.

In many infrastructure projects, galvanized steel guy wire is used together with wire mesh fencing or welded wire mesh panels to protect the base area of poles or towers. This combination provides both structural stability and perimeter safety, forming a complete project solution.

Choosing the Right Guy Wire for Your Project

When selecting galvanized steel guy wire, buyers and project managers should consider several factors:

-

Wire diameter and tensile strength requirements

-

Environmental conditions and corrosion exposure

-

Project duration and expected service life

-

Compatibility with anchors and installation hardware

Selecting the correct specifications ensures optimal performance and reduces long-term maintenance risks.

Conclusion

Galvanized steel guy wire is a critical support material for utility, telecom, and infrastructure projects. Its strength, durability, and corrosion resistance make it a reliable choice for stabilizing poles and towers in demanding outdoor environments. When combined with wire mesh or welded wire mesh fencing systems, it contributes to a complete and professional project solution that balances safety, stability, and cost efficiency.

For B2B buyers, sourcing galvanized steel guy wire directly from a qualified manufacturer ensures consistent quality, competitive pricing, and reliable supply for long-term projects.

Get Professional Wire Mesh Solutions for Poultry Projects

Looking for reliable chicken wire, welded wire mesh, or poultry fencing solutions for farms or bulk projects?

We supply factory-direct wire mesh with stable quality, export-ready packaging, and custom specifications.

📲 WhatsApp: +86 18830227875

Contact us now for technical support, samples, and a fast quotation.

Manufacturer | Wholesale Supply | OEM Available

Frequently Asked Questions (FAQ)

1. What is chicken wire used for?

Chicken wire is mainly used for poultry fencing, garden protection, and small animal enclosures. It helps keep chickens inside a designated area and protects plants from damage. For commercial farms or long-term use, many buyers upgrade to welded wire mesh for better strength and durability.

2. Is chicken wire strong enough to stop predators?

Chicken wire is not designed to stop strong predators. It works best for light protection and containment. For improved security, it is recommended to combine chicken wire with welded wire mesh at the lower section of the fence or choose heavier poultry wire mesh for predator-prone areas.

3. How deep should chicken wire be buried?

To prevent animals from digging under the fence, the bottom of the chicken wire should be buried at least 10–15 cm (4–6 inches) underground. In high-risk areas, extending the mesh outward as a ground apron provides additional protection.

4. What is better for poultry fencing: chicken wire or welded wire mesh?

Chicken wire is more flexible and cost-effective, making it suitable for small or temporary enclosures. Welded wire mesh offers higher strength, uniform openings, and longer service life, making it a better choice for large-scale chicken farms and permanent poultry fencing projects.

5. How long does chicken wire last outdoors?

The lifespan of chicken wire depends on the surface treatment. Electro-galvanized wire is suitable for short-term use, while hot-dip galvanized or PVC-coated chicken wire can last several years outdoors, even in humid or coastal environments.

6. How far apart should fence posts be for chicken wire fencing?

Fence posts are typically installed 1.5–2.5 meters (5–8 feet) apart. Shorter spacing helps reduce sagging, especially for longer fence runs or uneven ground.

Post a Comment