Barb Fence Wire: The Professional Guide for Perimeter Protection and Farm Fencing

Barb fence wire is one of the most widely used fencing solutions in agriculture, ranching, and security projects. As a classic wire product, it is designed to create a strong physical barrier that prevents livestock escape and deters unauthorized entry. Compared with other wire mesh products, barb wire is more flexible, easier to install over uneven terrain, and highly cost-effective for large-scale perimeter fencing.

In many projects, barb fence wire is not used alone but combined with other mesh products such as welded wire mesh, hexagonal wire mesh, and livestock fencing to form a complete fencing system. Choosing the right wire type is crucial because it directly affects durability, maintenance costs, and long-term performance.

1. What Is Barb Fence Wire and Why It Works?

Barb fence wire consists of two main wires twisted together, with sharp barbs placed at regular intervals along the wire. The barbs are designed to prevent animals from pushing through or climbing over the fence. This simple yet effective design provides both a physical barrier and a visual deterrent.

The wire itself is usually made from high-carbon steel, ensuring strong tensile strength and good elasticity. For outdoor applications, the wire is commonly coated with zinc through electro-galvanizing or hot-dip galvanizing. In some cases, PVC coating is applied for additional corrosion protection and improved appearance.

Barb fence wire is ideal for large perimeter projects because it can be installed quickly using posts and tensioning tools. Its flexibility allows it to follow uneven ground without the need for frequent intermediate posts, which reduces material and labor costs.

2. Material and Coating: Ensuring Long-Term Performance

The key to long-lasting barb fence wire is the material quality and surface treatment. High-carbon steel wire provides high tensile strength, making the fence resistant to stretching and breaking. The coating protects the wire from corrosion caused by rain, humidity, and chemicals commonly found in agricultural environments.

Common coating types include:

-

Electro-galvanized: Economical, suitable for general environments

-

Hot-dip galvanized: Thicker zinc layer, better corrosion resistance

-

PVC coated: Added protection and improved aesthetics

Compared with bare wire, coated barb fence wire can last significantly longer in outdoor environments. For farms in coastal or high-humidity regions, hot-dip galvanized or PVC-coated wire is recommended to avoid rust and reduce replacement frequency.

3. Barb Wire vs Welded Wire Mesh (Electric Welded Mesh)

Welded wire mesh is a common alternative to barb wire in many fencing projects. It is made by welding horizontal and vertical wires at intersections to form a stable mesh panel. This type of mesh is widely used for garden fences, security barriers, and industrial partitions.

Comparison:

-

Strength & Stability: Welded mesh has high rigidity and does not deform easily, making it suitable for stable, visible fencing. Barb wire is more flexible but requires tensioning for stability.

-

Appearance: Welded mesh offers a neat, panel-based look. Barb wire has a rougher, more rugged appearance.

-

Installation: Barb wire is faster to install over long distances and uneven ground. Welded mesh requires more posts and precise installation.

-

Cost: Barb wire is generally more economical for large perimeter fences. Welded mesh is more expensive but offers better visual and structural consistency.

In practice, many projects use both: welded mesh for visible boundaries and gate areas, and barb wire for long perimeter sections.

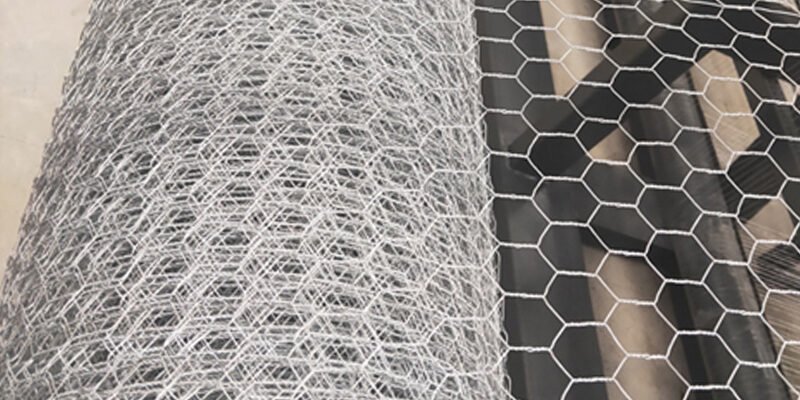

4. Barb Wire vs Hexagonal Wire Mesh (Chicken Wire)

Hexagonal wire mesh, also known as chicken wire, is commonly used in poultry farming, garden protection, and lightweight animal enclosures. Its hexagonal structure provides flexibility and can adapt to curved or irregular shapes.

Comparison:

-

Flexibility: Hexagonal mesh is more flexible and easy to shape. Barb wire is flexible but is mainly used as a linear barrier.

-

Purpose: Hexagonal mesh is ideal for small animal containment and garden protection. Barb wire is designed for perimeter security and livestock containment.

-

Safety: Hexagonal mesh is safer for animals and humans due to its smooth wire structure. Barb wire contains sharp barbs and should be used where safety measures are considered.

For farms, hexagonal mesh is often used inside the property for chicken coops and rabbit pens, while barb wire is used for outer perimeter protection.

5. Barb Wire vs Livestock Fencing (Cattle Fence / Field Fence)

Livestock fencing, also called field fence or cattle fence, is a type of woven wire mesh designed specifically for containing larger animals such as cattle, horses, and goats. It usually has small mesh openings at the bottom and larger openings at the top.

Comparison:

-

Containment: Livestock fencing is better for containing large animals without causing injury. Barb wire provides strong deterrence but can injure animals if they contact the barbs.

-

Application: Livestock fencing is used for internal farm partitions. Barb wire is used for outer boundaries and security.

-

Cost: Livestock fencing is generally more expensive due to its heavier structure. Barb wire is more economical for long boundary lines.

Many farms use livestock fencing for internal pens and barb wire for outer perimeter lines, creating a layered protection system.

Barbed Wire Security Fence

6. Best Applications for Barb Fence Wire

Barb fence wire is most suitable for:

-

Pasture and grazing land

-

Ranch perimeter fencing

-

Farm boundary protection

-

Security fences for industrial sites

-

Border and restricted area fencing

Because of its strong deterrent effect and cost efficiency, barb wire is a preferred choice for large land areas where continuous fencing is required.

7. Why Choose Factory Direct Barb Wire Supply?

For large-scale projects, factory direct supply offers advantages in price stability, consistent quality, and customization. We can provide:

-

Custom wire diameter and barb spacing

-

Different coating types (galvanized, PVC coated)

-

Bulk supply and export packaging

-

Technical support for installation and project design

Choosing a reliable barb wire manufacturer ensures that your fencing system remains durable and cost-effective over time.

8. Conclusion: A Practical Perimeter Solution

Barb fence wire remains one of the most efficient perimeter protection solutions for farms, ranches, and security areas. When combined with other wire mesh products such as welded mesh, hexagonal mesh, and livestock fencing, it forms a complete, layered fencing system that balances cost, durability, and safety.

If you are planning a large-scale fencing project, choosing the right wire type and supplier is essential for long-term performance and maintenance.

📲 WhatsApp: +86 18830227875

Contact us now to get technical details, samples, or a fast quotation.

Factory direct | Bulk supply | Export ready

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment