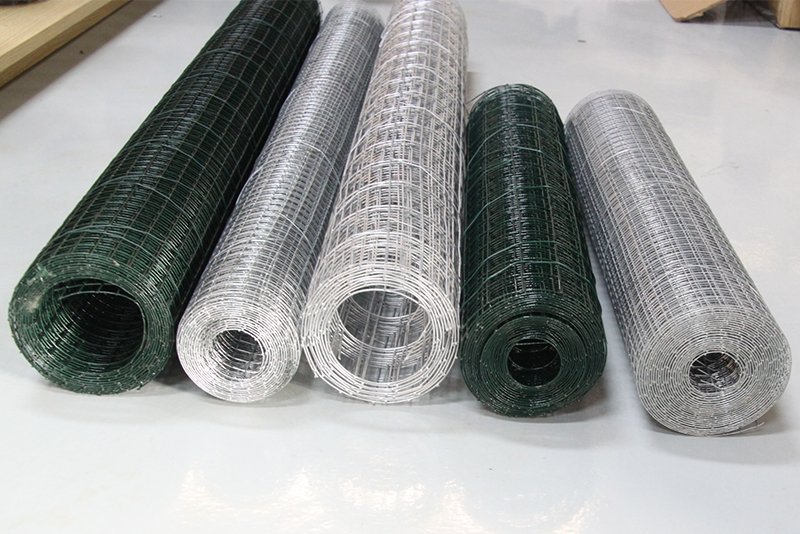

Rolled Wire Fencing for Professional Agricultural and Project Use

Rolled wire fencing is widely used in agricultural, industrial, and land management projects where large coverage, structural consistency, and cost efficiency are required. For B2B buyers, this fencing format is not simply a product—it is a scalable system designed for bulk transportation, fast installation, and long-term outdoor performance.

This article explains the product structure, manufacturing standards, and procurement considerations that matter most to wholesalers, distributors, and project contractors.

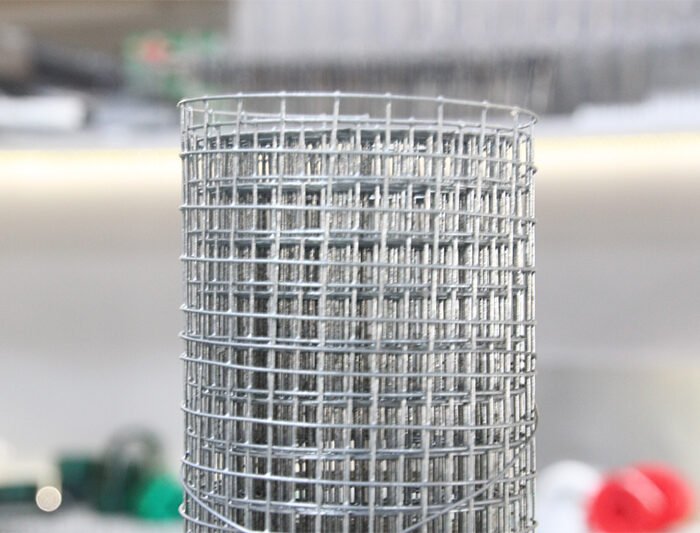

Product Structure and Manufacturing Characteristics

Wire fencing supplied in roll form is manufactured by weaving or welding steel wires into uniform mesh patterns, then wound into compact coils. This structure allows efficient handling and minimizes space during transport and storage.

Manufacturing quality depends heavily on:

-

Steel wire rod grade

-

Wire drawing accuracy

-

Mesh consistency

-

Surface treatment process

Factories with integrated production lines maintain tighter control over these elements, ensuring uniform strength and appearance across large batches.

Material Options and Surface Treatment

For professional applications, material selection directly impacts service life and total project cost. Low-carbon steel wire is commonly used for its balance of flexibility and tensile strength.

Surface treatment options typically include:

-

Electro-galvanized coating for moderate environments

-

Hot-dip galvanized coating for long-term outdoor exposure

Uniform zinc coating improves corrosion resistance and reduces maintenance needs, which is critical for agricultural and rural installations.

Typical Applications in B2B Projects

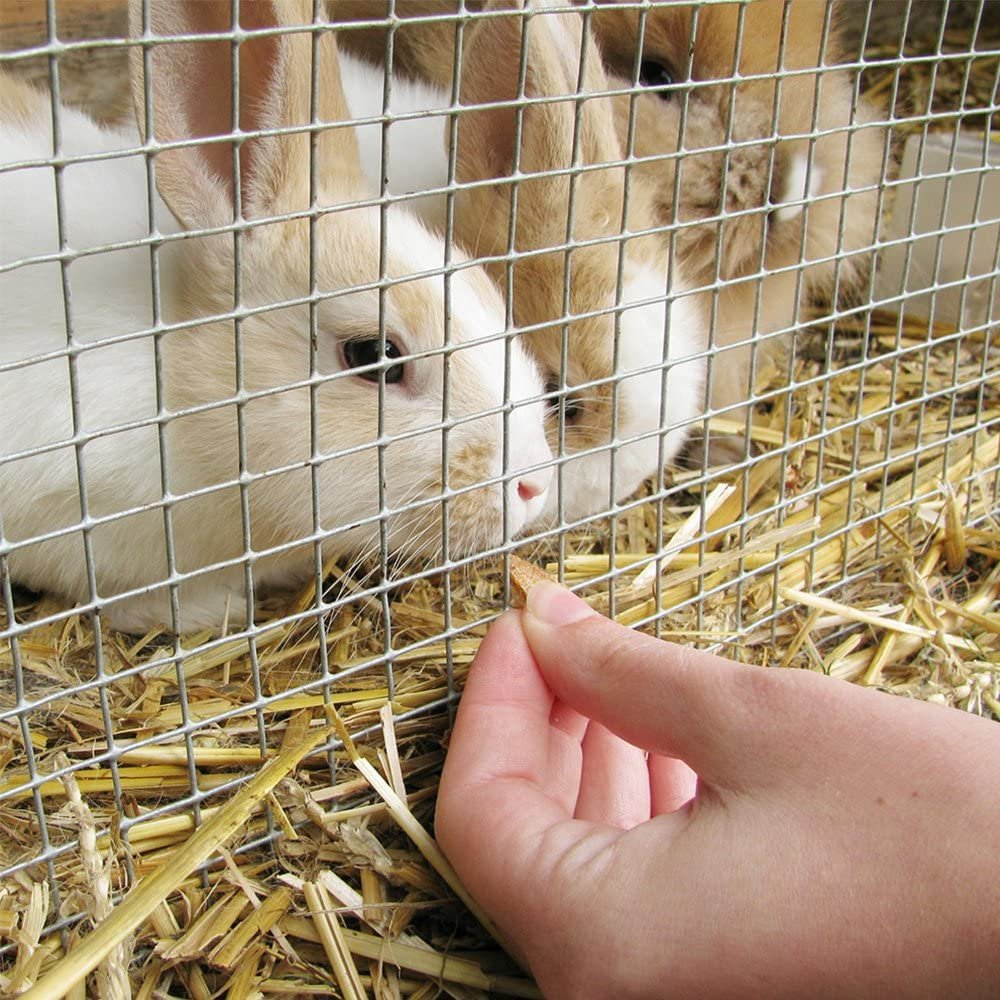

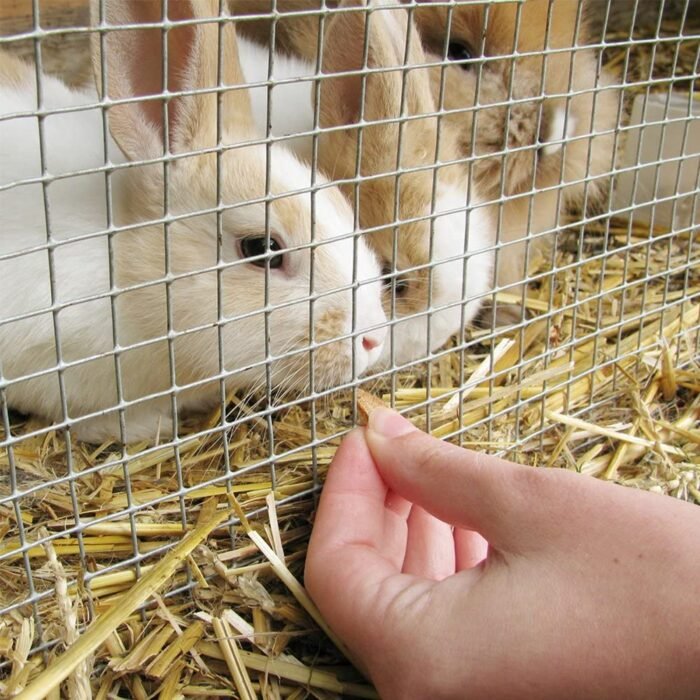

Wire fencing rolls are widely applied in:

-

Farmland boundary definition

-

Livestock enclosure systems

-

Pasture division and rotational grazing

-

Temporary or permanent land fencing

-

Agricultural infrastructure projects

Their adaptability allows contractors to use standardized materials across multiple sites while adjusting post spacing and installation methods as needed.

Advantages for Wholesale and Distribution Buyers

From a commercial perspective, fencing rolls offer clear advantages:

-

Efficient container loading

-

Reduced packaging waste

-

Lower freight cost per square meter

-

Easier inventory management

Distributors benefit from standardized roll sizes, while contractors appreciate reduced installation time on site.

Specification Customization for Project Needs

Factory-direct suppliers can customize:

-

Wire diameter

-

Mesh opening size

-

Roll length and height

-

Packaging method

This flexibility supports project-specific requirements and allows wholesalers to build differentiated product lines for their markets.

Installation Efficiency and Labor Considerations

Compared to rigid panels, rolled wire systems allow continuous installation along uneven terrain. This reduces cutting waste and speeds up deployment across large land areas.

Professional installers often prefer roll-form fencing when working on:

-

Sloped landscapes

-

Long boundary lines

-

Agricultural zones with limited access

Quality Control and Production Capacity

For B2B procurement, quality stability matters more than individual sample performance. Reliable manufacturers implement:

-

Wire diameter tolerance control

-

Coating thickness inspection

-

Tensile strength testing

-

Batch traceability

High production capacity also ensures stable supply for long-term or repeat orders.

Export Packaging and Logistics Support

Export-ready packaging protects wire rolls during ocean transport. Common options include:

-

Plastic film wrapping

-

Steel strapping

-

Wooden pallet loading

Professional factories also provide complete documentation, simplifying international logistics for importers.

Evaluating Total Procurement Value

Experienced buyers assess fencing systems based on:

-

Lifespan under local conditions

-

Installation efficiency

-

Supply consistency

-

After-sales support

This approach helps reduce hidden costs and improves long-term project outcomes.

Why Factory-Direct Supply Matters

Sourcing directly from manufacturers reduces intermediary markups and improves transparency. It also enables clearer communication regarding specifications, lead times, and quality standards.

For distributors and contractors, this sourcing model supports predictable pricing and scalable procurement.

A Reliable Solution for Large-Scale Fencing

When properly specified and sourced, rolled wire systems deliver a practical balance between performance and cost efficiency. For professional buyers seeking dependable fencing materials, rolled wire fencing remains a proven solution for agricultural and project-based applications.

Why Choose My Wire Mesh Factory

I operate a professional wire‑mesh factory with years of experience producing high‑quality metal mesh and fencing solutions. I use carefully selected raw materials and advanced production equipment to ensure each wire and mesh panel meets strict strength and corrosion‑resistance standards. My manufacturing line emphasizes precision welding, uniform mesh spacing, and robust surface galvanization, giving my products long service life even in harsh outdoor environments. I also support flexible customization — I adjust wire gauge, mesh size, and coating to meet clients’ exact requirements. This commitment to quality, consistency, and bespoke solutions defines my advantage in the steel‑wire‑mesh industry.

🔹 Related Products – Professional Wire Fencing Solutions

These products complement rolled wire systems and support a wide range of agricultural and industrial fencing projects. All items are sourced factory-direct with bulk supply, custom specifications, and export-ready packaging.

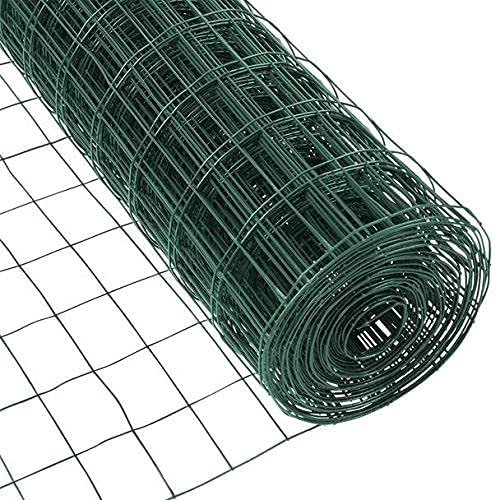

1. Welded Mesh Fence Panels

Heavy-duty mesh panels with welded intersections for strength and rigidity.

✔ Durable & consistent panel dimensions

✔ Ideal for farms, warehouses, and perimeter security

✔ Available in galvanized and PVC coated finishes

2. Woven Field Fencing Rolls

Flexible fencing rolls with interlocked wire design for livestock containment.

✔ Excellent impact resistance

✔ Suitable for cattle, sheep, and goats

✔ Custom roll lengths and wire gauges

3. Barbed Wire Coils

High-tensile galvanized wire with sharp barbs to enhance deterrence.

✔ Long service life outdoors

✔ Easy to combine with posts or mesh systems

✔ OEM & bulk pricing available