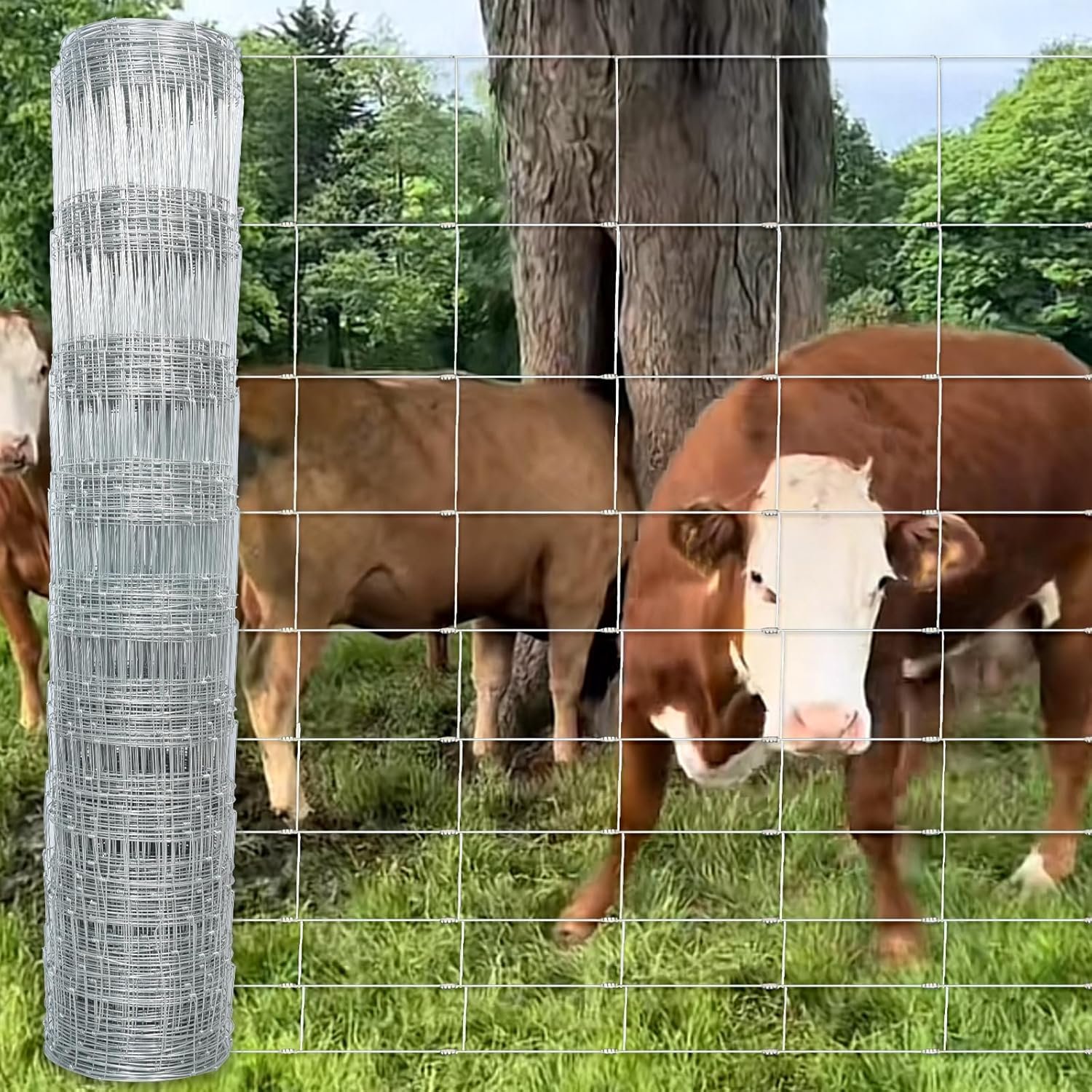

Cattle Wire Fencing for Large-Scale Livestock Projects

Cattle wire fencing plays a critical role in modern livestock management, especially for farms, ranches, and agricultural contractors handling large land areas. For professional buyers, choosing the right fencing system is less about appearance and more about durability, animal safety, and long-term cost control.

This article focuses on how B2B buyers evaluate cattle fencing solutions and what factors truly matter in bulk procurement.

Designed for Strength and Animal Control

Unlike decorative or residential fencing, livestock enclosures must withstand continuous pressure from animals. Properly designed farm fencing systems use high-tensile steel wire combined with fixed or hinged knots to maintain spacing under impact.

For cattle operations, consistent mesh openings are essential. They reduce the risk of animals pushing through the fence while allowing visibility and airflow across grazing areas.

Material Selection and Surface Treatment

Wire diameter and steel quality directly influence service life. Professional buyers usually select specifications based on land size, herd density, and local climate conditions.

Surface protection is another decisive factor. Galvanized wire with adequate zinc coating ensures corrosion resistance in outdoor environments, minimizing replacement frequency and labor costs over time. For export markets, coating consistency is often a key inspection point.

Adaptability Across Agricultural Applications

Livestock wire fence systems are widely used for:

-

Open pasture boundary control

-

Rotational grazing divisions

-

Cattle corridor and lane fencing

-

Mixed livestock farms requiring flexible layouts

Their adaptability allows contractors and distributors to standardize product ranges while serving multiple agricultural needs.

Manufacturing Capability Matters for B2B Buyers

For wholesalers and project buyers, sourcing directly from a manufacturer offers clear advantages. Integrated production lines—from wire drawing to weaving and surface treatment—ensure stable specifications and repeatable quality.

Large-scale factories also provide better control over lead times, packaging standards, and container loading efficiency, which is critical for long-term supply contracts.

Evaluating Total Project Value

Experienced buyers do not assess fencing systems solely on unit cost. Instead, they consider:

-

Wire strength consistency across batches

-

Resistance to deformation under animal pressure

-

Compatibility with posts and accessories

-

Reliability of long-term supply

This holistic evaluation helps protect project margins and reduces after-installation issues.

A Practical Choice for Professional Procurement

When properly specified and sourced, cattle wire fencing delivers a balanced solution for strength, flexibility, and economic efficiency. For distributors, importers, and agricultural contractors, it remains a dependable option for scalable livestock enclosure projects.

Quality Control and Export Readiness

Export-oriented manufacturers implement strict quality checks at every stage, from raw wire selection to final roll packaging. Proper bundling and moisture-resistant packing help protect fencing during long-distance transportation.

For international buyers, this translates into fewer claims, predictable delivery, and smoother distribution.

Choosing a Long-Term Supply Partner

Beyond product specifications, professional buyers should evaluate:

-

Production experience in livestock fencing

-

Understanding of agricultural standards

-

Ability to support bulk and repeat orders

-

Clear communication on lead times

A stable manufacturing partner is essential for maintaining supply continuity in agricultural markets.

Conclusion

For wholesalers and agricultural project buyers seeking a durable and field-proven fencing solution, woven wire goat fence remains a reliable choice when sourced from an experienced manufacturer. With strong structure, export-friendly packaging, and scalable production, this fencing type continues to meet the demands of modern livestock operations.

👉 If you are sourcing woven livestock fencing for goats in bulk, contact us to discuss specifications, capacity, and manufacturer-direct pricing.

Factory Overview – TS Wire Mesh

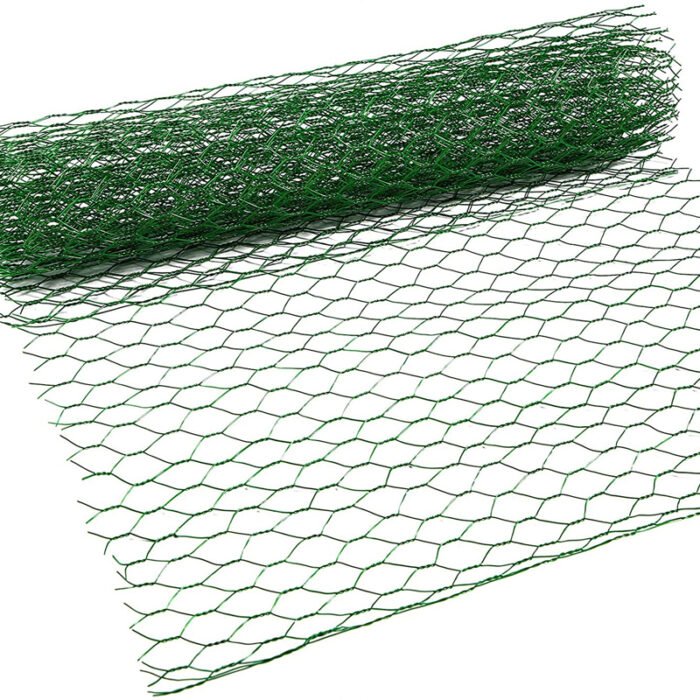

TS Wire Mesh is a professional manufacturer specializing in high-quality wire mesh products for over 20 years. The factory produces a wide range of items including hexagonal wire mesh, welded wire mesh, PVC-coated wire mesh, hardware cloth, barbed wire, and related iron wire products.

Every product is made with precision and undergoes strict quality control to ensure uniform mesh size, consistent wire diameter, and reliable tensile strength.

Advanced production equipment and skilled technicians enable TS Wire Mesh to offer both standard and customized solutions for agricultural, industrial, and construction applications. Products are crafted with galvanized steel, stainless steel, or PVC-coated wire to ensure durability, corrosion resistance, and long service life under various environmental conditions. The factory also maintains an export-oriented workflow, providing stable supply, secure packaging, and efficient shipping to international markets.

With professional experience and a customer-first approach, TS Wire Mesh supports buyers with detailed specifications, fast quotations, and responsive service, making sourcing wire mesh easy and reliable.

For inquiries, pricing, or custom orders, contact directly on WhatsApp: +86 18830227875.

-

Related Products You May Like

-

Welded Wire Mesh

Heavy-duty galvanized or PVC-coated welded wire mesh, ideal for fencing, construction reinforcement, garden protection, and DIY projects. -

Galvanized Steel Wire

High-quality steel wire for construction, crafting, binding, and general industrial use. Flexible, strong, and corrosion-resistant. -

Common & Roofing Nails

Durable iron nails, including common nails, roofing nails with umbrella heads, and galvanized options. Perfect for construction, carpentry, and fencing applications.

-