B2B Price Analysis: What Determines Barbed Wire Costs?

Barbed wire fence price is one of the first concerns for importers, wholesalers, and project contractors planning large-scale fencing. However, for B2B buyers, unit cost is never a single number—it is the result of material choices, specifications, order volume, and supply chain stability.

This article breaks down the real pricing logic behind barbed wire fencing, helping professional buyers evaluate offers accurately and avoid misleading low quotes.

1. Raw Material and Wire Gauge Impact Cost Directly

Steel wire rod is the foundation of barbed wire production. Fluctuations in steel prices immediately affect fencing costs, especially for bulk orders.

In addition, wire diameter plays a major role. Thicker line wires and barbs require more steel per ton, increasing durability but also raising overall cost. For agricultural or perimeter projects, buyers often balance lifespan against budget rather than choosing the thickest option blindly.

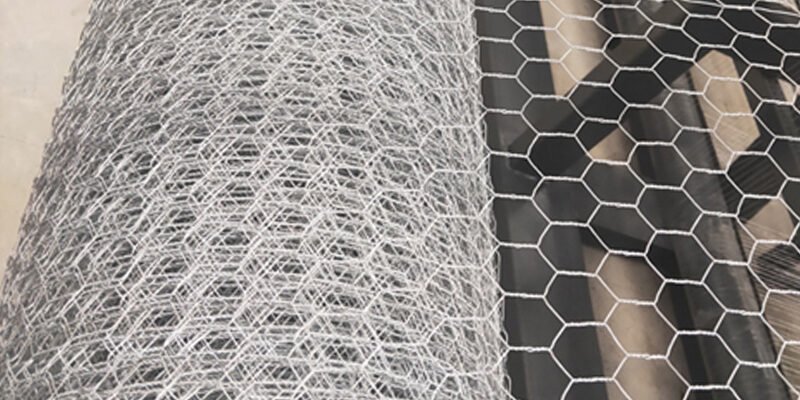

2. Surface Treatment and Corrosion Resistance

Different galvanizing methods create noticeable cost differences.

-

Electro-galvanized wire offers lower upfront cost and smooth appearance

-

Hot-dip galvanized wire provides heavier zinc coating and longer outdoor service life

For long-term installations such as farmland boundaries or livestock fencing, higher corrosion resistance usually delivers better total project value despite a higher initial wire fencing cost.

3. Order Quantity and Packaging Configuration

Volume strongly influences unit pricing. Full container orders reduce production changeover time, packaging cost, and freight per ton.

Export packaging—such as wooden pallets, steel straps, or moisture-proof wrapping—also affects final quotations. Buyers sourcing for resale or distribution should factor packaging standards into comparisons, not just base wire pricing.

4. Manufacturing Capability and Supply Stability

Factory-scale producers with in-house wire drawing, galvanizing, and twisting lines generally offer more stable pricing than trading-only suppliers.

Consistent quality control reduces claim risks, while steady monthly output ensures on-time delivery for long-term projects. These factors often matter more than marginal differences in per-ton cost.

5. How Professional Buyers Evaluate Total Cost

Experienced importers rarely judge offers solely on barbed wire fence price. Instead, they compare:

-

Service life per installation environment

-

Zinc coating consistency

-

Diameter tolerance

-

Order repeatability and lead time reliability

This approach minimizes hidden costs and protects downstream project margins.

FAQ for B2B Buyers (Schema-Ready)

What factors influence barbed wire fencing cost the most?

Steel raw material price, wire diameter, galvanizing method, and total order volume are the main drivers.

Is thicker barbed wire always more cost-effective?

Not always. Thicker wire lasts longer, but thinner specifications may offer better cost efficiency for short-term or low-risk applications.

Why do factory-direct suppliers offer more stable pricing?

Manufacturers control production steps directly, reducing reliance on third parties and minimizing sudden cost fluctuations.

Does packaging affect export pricing significantly?

Yes. Pallet type, bundling method, and moisture protection all influence logistics cost and final landed pricing.

How can buyers avoid unrealistically low quotes?

Check zinc coating weight, wire tolerance, and production standards. Extremely low offers often sacrifice durability or consistency.

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment