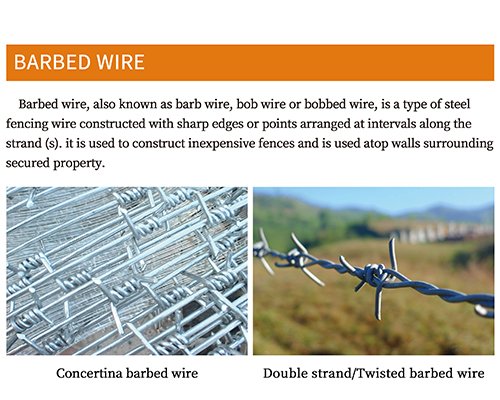

Barbed Wire Fence Installation for Agricultural and Security Projects

Barbed wire fence installation remains a widely adopted solution for agricultural boundaries, land protection, and basic security applications. For wholesalers, fencing material suppliers, and project contractors, barbed fencing systems offer a cost-effective and scalable option that can be applied across large rural and industrial areas.

In B2B procurement, the focus is not on small-scale installation details, but on material reliability, consistency, and suitability for repeated project use.

Why Barbed Fencing Is Still Used in Professional Projects

Despite the availability of modern fencing systems, barbed fencing continues to play an important role in large-area enclosures. Its effectiveness lies in simplicity and coverage efficiency.

Professional buyers value barbed fencing systems because they provide:

-

Wide-area protection at low material cost

-

Fast deployment over long distances

-

Minimal structural complexity

-

Proven deterrent function for livestock and property

These characteristics make barbed fencing especially suitable for farms, ranches, and land management projects.

Typical Applications in B2B Markets

Barbed fencing solutions are commonly specified in:

-

Cattle and livestock ranches

-

Agricultural land boundaries

-

Industrial and warehouse perimeters

-

Temporary or secondary security lines

For distributors, this broad application range ensures stable and recurring demand.

Materials and Wire Specifications

From a manufacturing perspective, barbed wire products are designed for strength and durability rather than appearance. Buyers usually evaluate:

-

Wire material: low-carbon or high-tensile steel

-

Wire diameter: matched to required tension strength

-

Barb spacing and sharpness: standardized for deterrence

-

Surface treatment: heavy galvanizing for corrosion resistance

Consistent raw material quality is critical for maintaining performance during long fence runs.

Barbed Wire Security Fence

Installation Efficiency for Large-Scale Projects

In commercial fencing construction, efficiency matters. Barbed fencing systems are favored because they:

-

Require fewer structural components

-

Can be installed with wooden or steel posts

-

Adapt to uneven terrain

-

Reduce labor time per kilometer

These advantages directly impact project cost control and delivery schedules.

Wholesale and Project Supply Advantages

For wholesalers and importers, barbed wire products offer strong commercial benefits:

-

Supplied in coils for compact storage

-

High container loading efficiency

-

Long shelf life with minimal maintenance

-

Easy bundling with posts and accessories

These features make barbed fencing a dependable product line in fencing material portfolios.

Manufacturer-Direct Sourcing Benefits

Working directly with a barbed wire manufacturer allows B2B buyers to:

-

Secure factory-level pricing

-

Request custom wire diameters or coatings

-

Ensure stable production capacity for seasonal demand

-

Maintain consistent quality across repeat orders

This sourcing model is especially valuable for agricultural supply chains.

Quality Control and Export Readiness

Professional manufacturers apply quality checks on wire tensile strength, barb formation, and coating thickness. Proper coil packing and moisture protection ensure safe long-distance transport.

For international buyers, this reduces claims and improves supply reliability.

Conclusion

For wholesalers and project buyers managing large land or agricultural enclosures, barbed wire fence installation continues to be a practical solution when supported by consistent materials and experienced manufacturing. With efficient deployment, low cost per meter, and stable supply capability, barbed fencing remains a relevant choice in modern B2B fencing markets.

👉 If you are sourcing barbed wire for wholesale or project use, contact us to discuss specifications, capacity, and factory-direct pricing.

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment