5/6 ft Welded Wire Fencing for Secure and Long-Lasting Enclosures

5/6 ft welded wire fencing is one of the most widely used fencing solutions for farms, gardens, animal enclosures, and light industrial protection. With its balanced height, rigid structure, and reliable welded joints, this type of wire fence offers both visibility and security while remaining cost-effective and easy to install.

Whether you are enclosing livestock, protecting crops, or defining property boundaries, welded wire fencing at 5 or 6 feet high delivers dependable performance in a wide range of environments.

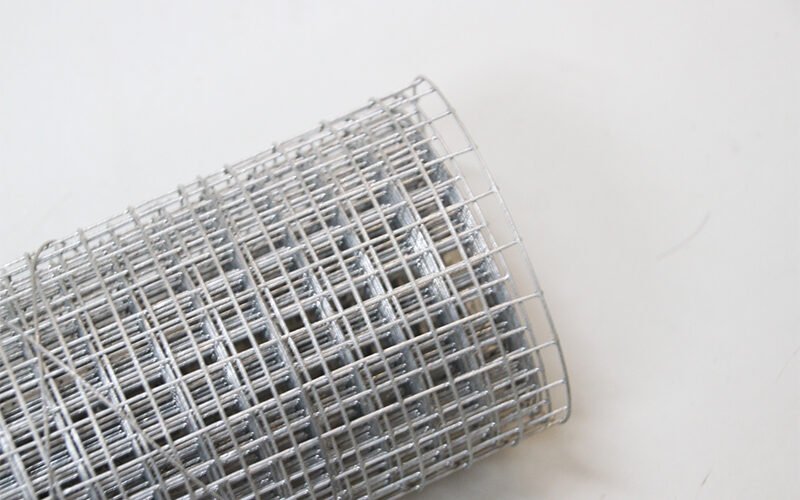

weld wire

Key Product Advantages

Strong Welded Structure

Unlike woven or twisted fencing, welded wire fencing is manufactured by electrically welding intersecting steel wires at each crossing point. This creates a rigid panel or roll that resists deformation, sagging, and impact. Even under pressure from animals or outdoor forces, the fence maintains its shape and strength.

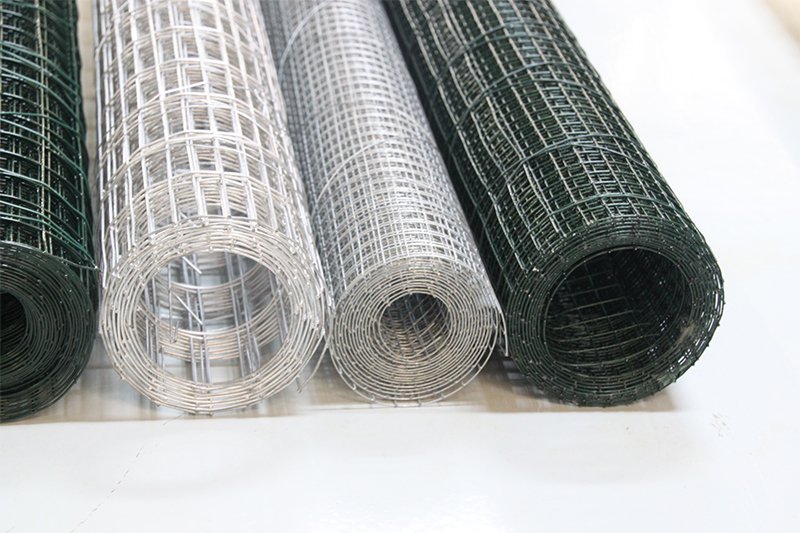

Durable Steel Materials

Most 5/6 ft welded wire fencing is made from low-carbon steel wire with galvanized or PVC-coated finishes. Galvanized steel provides excellent rust resistance for outdoor use, while PVC coating adds an extra protective layer and improves appearance, especially for residential or garden applications.

Ideal Height for Multiple Uses

A height of 5 or 6 feet offers effective containment without feeling overly closed or bulky. It is tall enough to prevent animals from jumping over, while still allowing airflow and visibility. This makes it suitable for livestock fencing, dog runs, garden protection, poultry areas, and perimeter barriers.

Common Applications

Thanks to its versatility, welded wire fencing is used across many sectors:

-

Farm fencing for goats, sheep, cattle, and poultry

-

Garden fencing to protect plants from animals

-

Dog and pet enclosures with secure boundaries

-

Property and perimeter fencing for residential or commercial sites

-

Temporary construction fencing and storage areas

Its clean grid structure also makes it easy to attach to posts, frames, or existing fence systems.

How to Choose the Right Welded Wire Fence

Mesh Size Matters

Smaller mesh openings provide better protection against small animals, while larger openings reduce cost and improve visibility. Choose mesh size based on the animals or security level required.

Wire Diameter and Strength

Thicker wire offers higher tensile strength and longer service life, especially in high-impact or livestock environments. For long-term outdoor use, heavier wire gauges are recommended.

Surface Treatment

For humid, coastal, or rainy regions, hot-dip galvanized fencing is the most durable option. PVC-coated fencing is ideal when aesthetics and extra corrosion protection are important.

weld wire mesh

Factory Supply and Custom Options

As a professional wire mesh manufacturer, we supply 5/6 ft welded wire fencing in rolls or panels with customizable mesh sizes, wire diameters, and surface treatments. All products are produced under strict quality control to ensure consistent weld strength and export-grade durability.

Bulk orders, OEM packaging, and custom specifications are available for distributors, contractors, and importers.

Our Factory Advantages

With years of experience in wire and mesh manufacturing, TS Wire Mesh is a professional factory specializing in metal wire, wire mesh fencing, and custom steel products for global markets. We focus on stable quality, factory-direct pricing, and long-term cooperation with wholesalers, distributors, and project buyers worldwide.

1. Factory-Direct Manufacturing, Competitive Pricing

As a source manufacturer, we control the entire production process—from raw material selection to wire drawing, welding, weaving, surface treatment, and packing. This direct factory operation eliminates unnecessary middle costs, allowing us to offer competitive ex-factory prices while maintaining consistent quality. OEM and bulk orders are always welcome.

2. Strict Raw Material & Quality Control

We use carefully selected low-carbon steel wire, high-carbon steel wire, galvanized steel wire, and stainless steel wire sourced from qualified steel mills. Every production stage follows internal quality inspection standards, including wire diameter tolerance, zinc coating thickness, weld strength, and tensile performance. Export-grade quality control ensures stable performance in different climates and applications.

3. Wide Product Range, One-Stop Supply

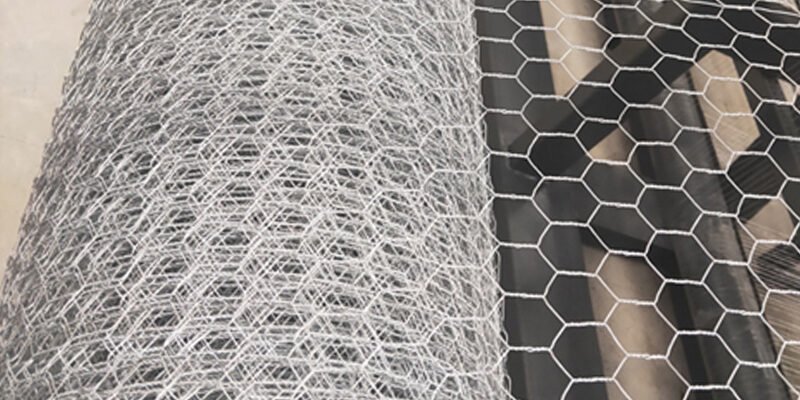

Our factory produces a complete range of wire and mesh products, including:

-

Hexagonal wire mesh (chicken wire)

-

Field fence & livestock fencing

-

Galvanized / PVC coated iron wire

-

Steel cable wire rope

This one-stop supply capability helps buyers reduce sourcing time, logistics costs, and communication risks.

4. Customization & OEM Capability

We support custom specifications such as wire diameter, mesh opening, panel size, roll length, surface finish, and packaging design. Our technical team works closely with customers to meet market standards in North America, Europe, Africa, and the Middle East. Private label and OEM packaging are fully supported.

5. Export Experience & Reliable Delivery

With rich export experience, we are familiar with international trade processes, packaging requirements, and container loading solutions. Stable production capacity and efficient scheduling allow us to ensure on-time delivery for both small trial orders and large-volume shipments.

6. Professional Service & Long-Term Partnership

Our team understands B2B buyers’ real needs—quality stability, clear communication, and after-sales responsibility. We aim to build long-term partnerships, not just one-time transactions, by providing honest quotations, fast responses, and continuous support.

Post a Comment