Wire garden fence solutions are a practical and cost-effective way to protect plants, define outdoor spaces, and keep unwanted animals out of your garden. Whether you manage a small backyard plot or a larger landscape area, choosing the right metal fencing plays a key role in durability, appearance, and long-term maintenance. From my experience working with wire mesh products, understanding material differences helps gardeners make smarter decisions and avoid frequent replacements.

Why Wire Fencing Is Ideal for Garden Use

Metal garden fencing stands out for its balance of strength and flexibility. Unlike wooden borders that rot or plastic barriers that crack under sunlight, wire-based fences maintain their shape and performance across seasons. Galvanized or PVC-coated steel resists rust, rain, and soil moisture, making it suitable for long-term outdoor installation.

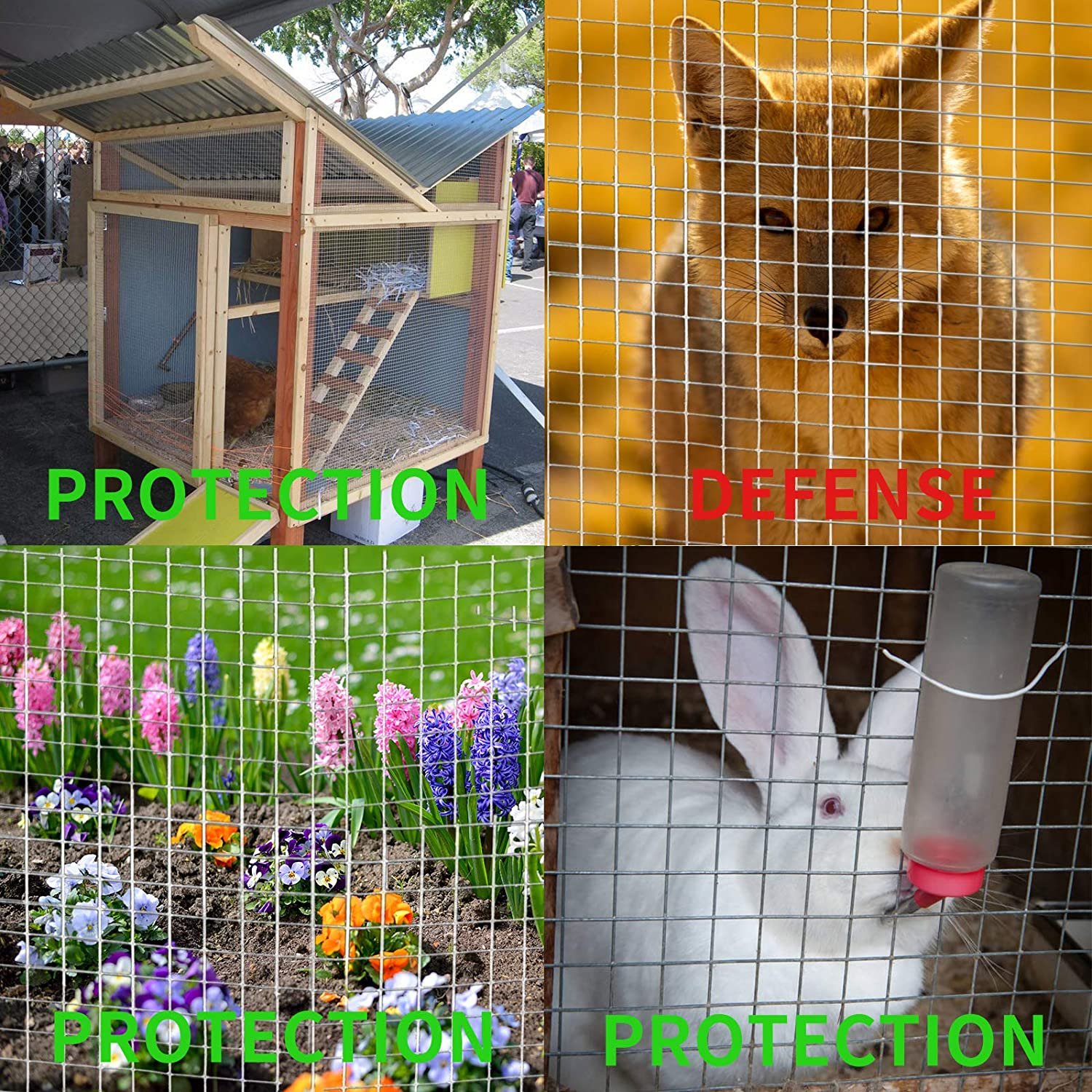

Another major advantage is airflow and visibility. Open mesh designs allow sunlight, air circulation, and irrigation to reach plants while still providing a physical barrier against pets, rabbits, or other small animals. This makes wire fencing especially popular for vegetable beds, flower borders, and climbing plants.

Common Applications in Gardens and Yards

Garden wire fencing adapts to many scenarios without complex tools or foundations. Typical uses include:

-

Protecting vegetable beds from rabbits and cats

-

Creating borders around flower beds and shrubs

-

Supporting climbing plants such as beans, tomatoes, or vines

-

Dividing garden zones for functional landscaping

-

Temporary fencing for seasonal planting areas

Its lightweight structure allows for easy cutting, bending, and shaping, which is ideal for DIY garden projects.

weld wire mesh

Hexagonal Wire Mesh vs Welded Wire Mesh in Gardens

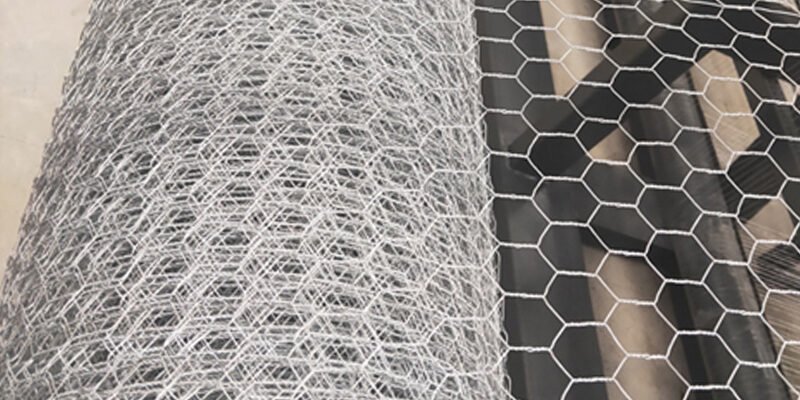

When choosing a garden fence, the two most common options are hexagonal wire mesh (also known as chicken wire) and welded wire mesh. Each has its own strengths depending on garden needs.

Hexagonal wire mesh is flexible and lightweight. Its twisted hexagon pattern allows it to conform easily to uneven ground or curved layouts. Gardeners often prefer it for flower beds, small plant protection, and decorative fencing. It is easy to install with basic tools and works well for keeping out small animals. However, due to its flexibility, it offers lower rigidity and is not ideal for areas requiring strong structural support.

Welded wire mesh, on the other hand, features straight wires welded at each intersection. This creates a rigid and stable structure that holds its shape over time. It is well suited for vegetable gardens, raised beds, and areas where stronger protection is required. Welded mesh panels provide better resistance against bending or animal pressure, though they are slightly heavier and less flexible during installation.

In simple terms, hexagonal mesh works best for light-duty and decorative garden fencing, while welded mesh is the better choice for durability and long-term structure.

Material and Surface Treatment Considerations

Beyond mesh type, surface treatment matters. Galvanized wire offers basic rust protection and suits most gardens. PVC-coated wire adds an extra layer of corrosion resistance and improves appearance, blending better with greenery. For humid or coastal regions, heavier zinc coating or PVC coating significantly extends service life.

Buying Guide: How to Choose the Right Garden Wire Fence

Before purchasing, consider these factors:

-

Animal size – Smaller mesh openings prevent rabbits and rodents from passing through

-

Fence height – Taller fencing offers better protection for vegetables and shrubs

-

Mesh rigidity – Flexible mesh for curved areas, rigid mesh for straight lines

-

Surface finish – Choose galvanized or PVC coated wire for outdoor durability

-

Installation method – Stakes, posts, or frames depending on garden layout

Selecting the right balance between flexibility and strength ensures long-term satisfaction.

Final Thoughts

A well-chosen wire garden fence enhances both the function and appearance of outdoor spaces. By comparing mesh types and understanding material performance, gardeners can build reliable protection without unnecessary cost. Used correctly, wire fencing becomes a long-lasting solution that supports healthy plant growth and cleaner garden design.

Our Factory Advantages

With years of experience in wire and mesh manufacturing, TS Wire Mesh is a professional factory specializing in metal wire, wire mesh fencing, and custom steel products for global markets. We focus on stable quality, factory-direct pricing, and long-term cooperation with wholesalers, distributors, and project buyers worldwide.

1. Factory-Direct Manufacturing, Competitive Pricing

As a source manufacturer, we control the entire production process—from raw material selection to wire drawing, welding, weaving, surface treatment, and packing. This direct factory operation eliminates unnecessary middle costs, allowing us to offer competitive ex-factory prices while maintaining consistent quality. OEM and bulk orders are always welcome.

2. Strict Raw Material & Quality Control

We use carefully selected low-carbon steel wire, high-carbon steel wire, galvanized steel wire, and stainless steel wire sourced from qualified steel mills. Every production stage follows internal quality inspection standards, including wire diameter tolerance, zinc coating thickness, weld strength, and tensile performance. Export-grade quality control ensures stable performance in different climates and applications.

3. Wide Product Range, One-Stop Supply

Our factory produces a complete range of wire and mesh products, including:

-

Welded wire mesh & panels

-

Hexagonal wire mesh (chicken wire)

-

Field fence & livestock fencing

-

Barbed wire & razor wire

-

Galvanized / PVC coated iron wire

-

Steel cable wire rope

This one-stop supply capability helps buyers reduce sourcing time, logistics costs, and communication risks.

4. Customization & OEM Capability

We support custom specifications such as wire diameter, mesh opening, panel size, roll length, surface finish, and packaging design. Our technical team works closely with customers to meet market standards in North America, Europe, Africa, and the Middle East. Private label and OEM packaging are fully supported.

5. Export Experience & Reliable Delivery

With rich export experience, we are familiar with international trade processes, packaging requirements, and container loading solutions. Stable production capacity and efficient scheduling allow us to ensure on-time delivery for both small trial orders and large-volume shipments.

6. Professional Service & Long-Term Partnership

Our team understands B2B buyers’ real needs—quality stability, clear communication, and after-sales responsibility. We aim to build long-term partnerships, not just one-time transactions, by providing honest quotations, fast responses, and continuous support.

Post a Comment