Rolled Metal Fencing Solutions for Secure Outdoor Use

Rolled metal fencing is a practical choice for projects that require flexibility, strength, and easy installation. I often recommend this fencing type because it combines durability with convenience, making it suitable for both professional contractors and DIY users. Supplied in compact rolls, it reduces transportation costs and allows installers to handle long fence runs efficiently on site.

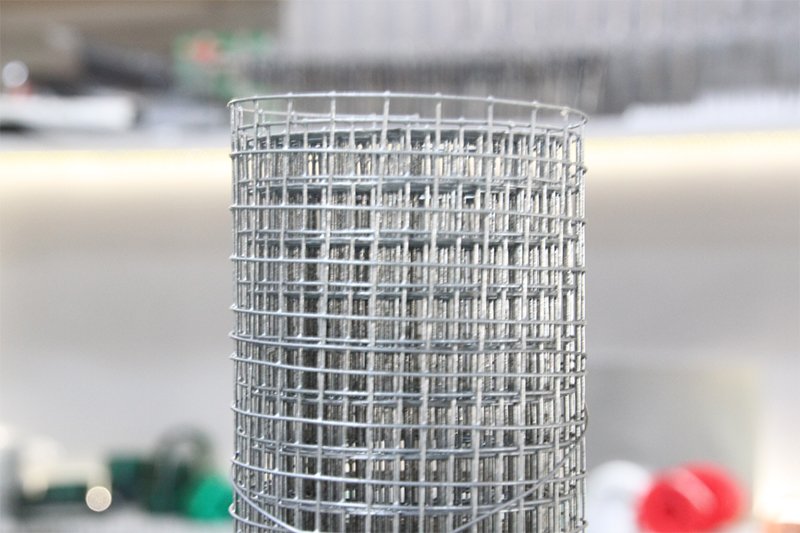

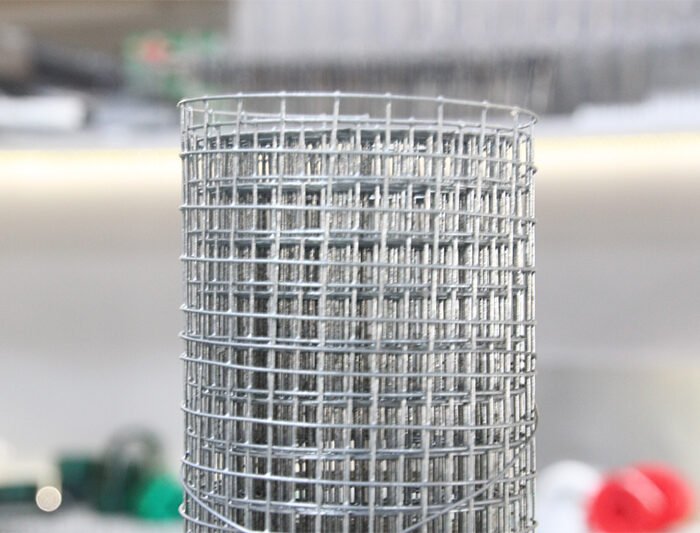

The core advantage of this fencing lies in its structure. Manufactured from galvanized or coated steel wire, it offers reliable resistance to rust and outdoor exposure. The rolled format allows the mesh to follow uneven ground, which makes it especially useful for gardens, farms, and temporary enclosures. Compared with rigid panels, this fencing adapts better to changing layouts and saves time during installation.

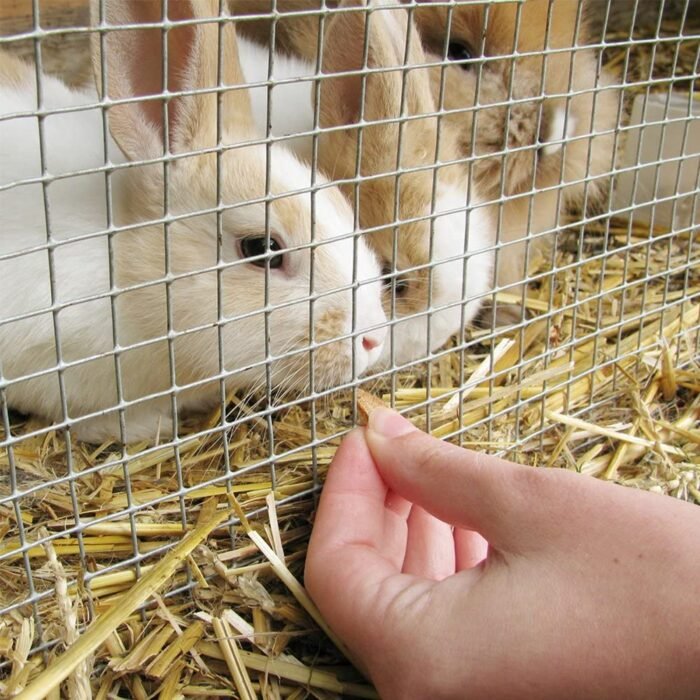

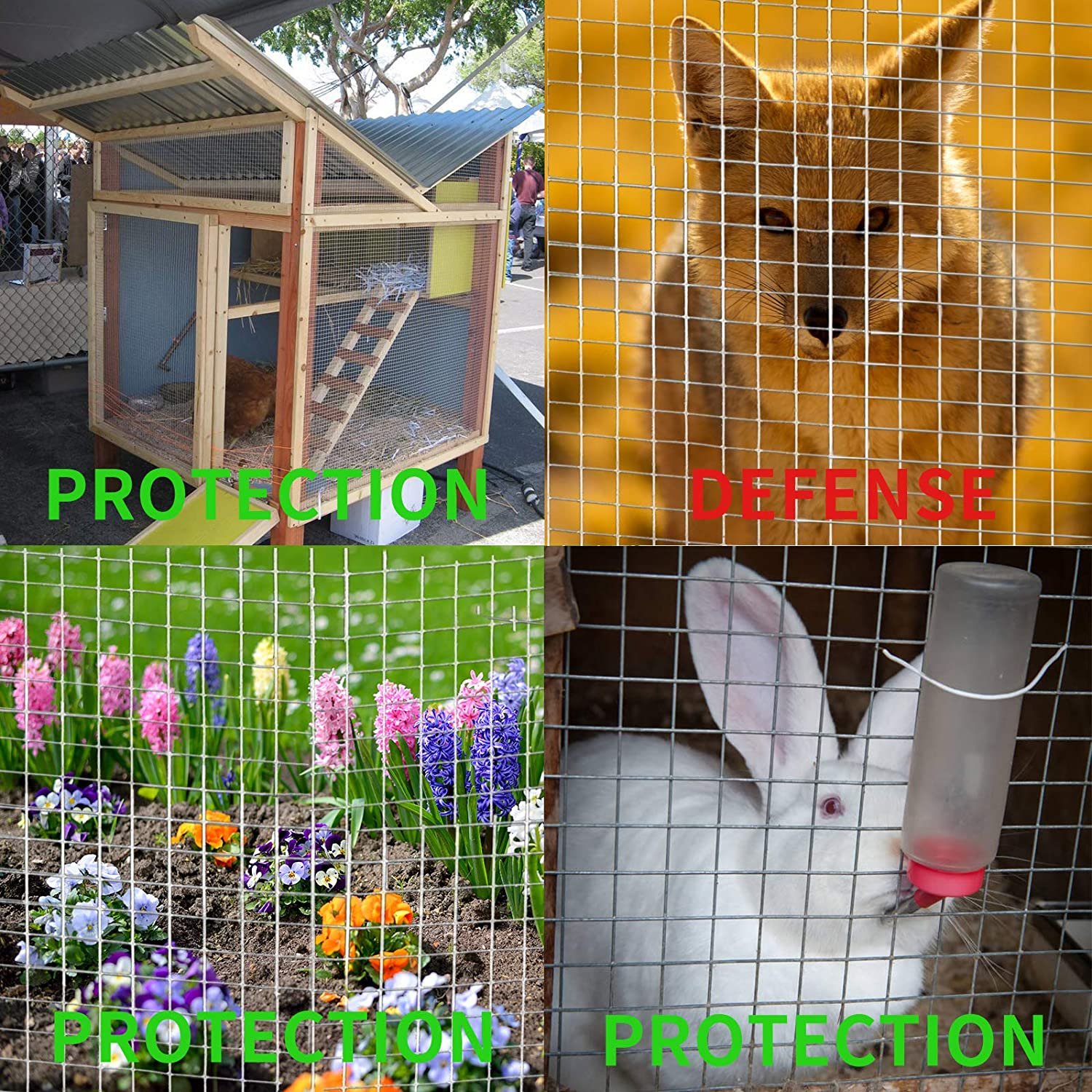

Another reason buyers choose this fencing is versatility. It works well for garden borders, poultry fencing, livestock separation, pet enclosures, and light security applications. The open mesh design maintains airflow and visibility while clearly defining boundaries. Different wire diameters and mesh openings allow users to select the right balance between strength and cost for their specific needs.

From a sourcing perspective, rolled metal fencing delivers strong value. It offers long service life with minimal maintenance and can be reused or relocated when project requirements change. When selecting a product, I always advise confirming wire gauge, surface treatment, and roll size to ensure the fencing meets performance expectations. With the right specifications, rolled fencing provides a reliable and economical solution for a wide range of outdoor fencing applications.

weld wire mesh

Product Selling Points

Flexible Roll Form for Easy Installation

Rolled metal fencing is supplied in compact rolls, making it easy to transport, store, and install. It can be quickly unrolled and cut to size on site, reducing labor time and installation costs for both temporary and permanent fencing projects.

Strong Structure with Reliable Durability

Manufactured from galvanized or coated steel wire, this fencing provides solid structural strength while resisting rust and weather exposure. It maintains stability under outdoor conditions and performs well in gardens, farms, animal enclosures, and light security applications.

Wide Range of Applications

This fencing works effectively for garden borders, livestock control, pet enclosures, poultry fencing, landscaping, and DIY projects. Its open mesh design allows airflow and visibility while keeping animals and boundaries clearly defined.

Cost-Effective Fencing Solution

Compared with rigid panels, rolled fencing offers a more economical option without sacrificing performance. Buyers benefit from lower shipping costs and flexible usage across multiple projects.

Buying Guide

When selecting rolled metal fencing, start by confirming the wire diameter and mesh opening size based on your application. Thicker wires provide better strength for animal control or perimeter fencing, while lighter gauges suit garden or decorative use.

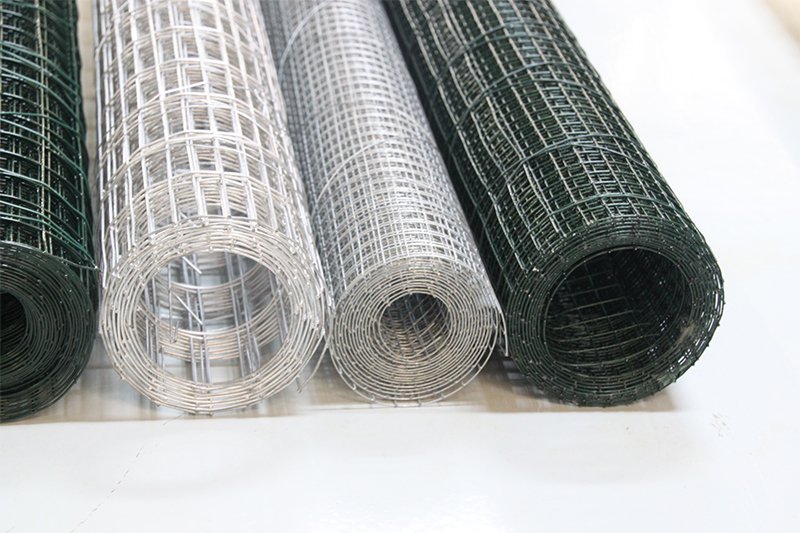

Next, consider the surface treatment. Hot-dip galvanized fencing offers long-term corrosion resistance, while PVC-coated options provide added protection and a cleaner appearance. The right coating depends on exposure to moisture and expected service life.

Roll length and fence height are also important. Longer rolls reduce joints and installation time, while proper height ensures effective containment. For bulk orders or custom specifications, factory-direct sourcing helps ensure consistent quality and stable lead times.

Factory Strength & Manufacturing Expertise

I operate a wire mesh manufacturing facility with years of hands-on experience in producing welded wire mesh and coated wire products for global markets. From raw wire drawing to welding, PVC coating, and final inspection, I control every production step to ensure stable quality and consistent specifications.

The factory uses automated welding machines and uniform coating lines to achieve precise mesh openings, strong weld points, and smooth, even PVC coverage. Each batch undergoes strict quality checks for wire diameter, coating adhesion, corrosion resistance, and dimensional accuracy before packing.

I also place strong emphasis on packaging and logistics. Reinforced cartons and palletized loading reduce deformation and damage during transport. With flexible OEM options, stable supply capacity, and fast response on custom requirements, the factory supports both small trial orders and large-volume projects with reliable lead times.

Contact Us

If you need technical advice, specifications, or pricing for wire mesh products, I am ready to assist you directly. Share your application details, required sizes, and quantity, and I will help you choose the right solution efficiently.

WhatsApp: +18830227875

Website: https://tswiremesh.com/

Feel free to contact me for fast quotations, custom orders, or factory support.