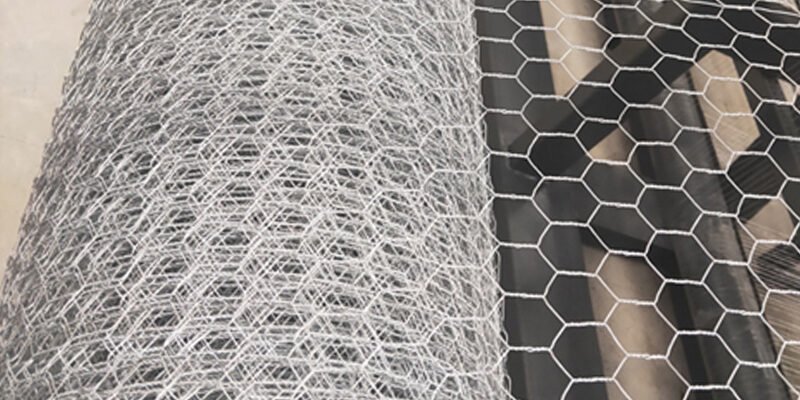

Understanding the standard size of welded wire mesh is essential for contractors, fabricators, and anyone selecting reinforcement or fencing materials for construction or agricultural projects. Welded mesh is produced by joining steel wires at their intersections using automated welding, creating strong, stable, and highly uniform grid panels.

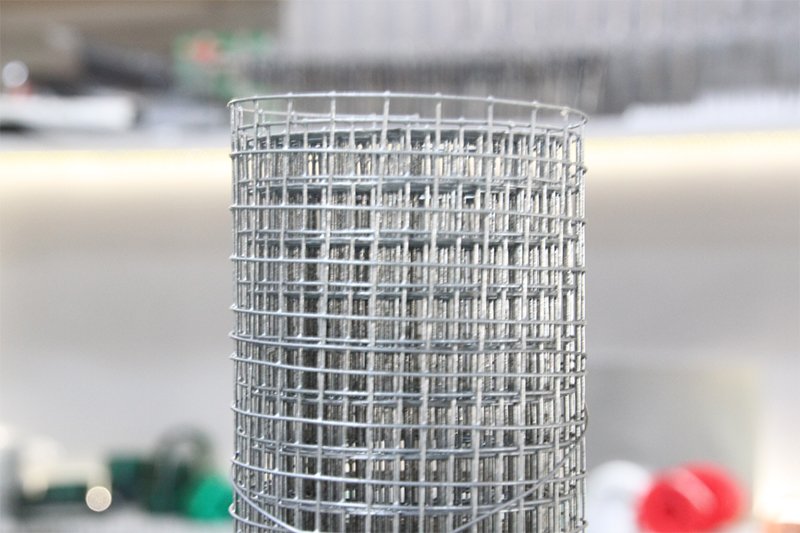

Most manufacturers follow internationally recognized panel formats to simplify transport and installation. Typical sheets come in widths of 1 meter, 1.2 meters, 2 meters, or 2.4 meters, while standard lengths range from 2 meters up to 6 meters. The mesh openings—also known as aperture sizes—vary based on use. For example, 50×50 mm, 100×100 mm, and 150×150 mm patterns are commonly used in concrete reinforcement, while smaller openings such as 12.5×12.5 mm or 25×25 mm are preferred for animal cages or security enclosures.

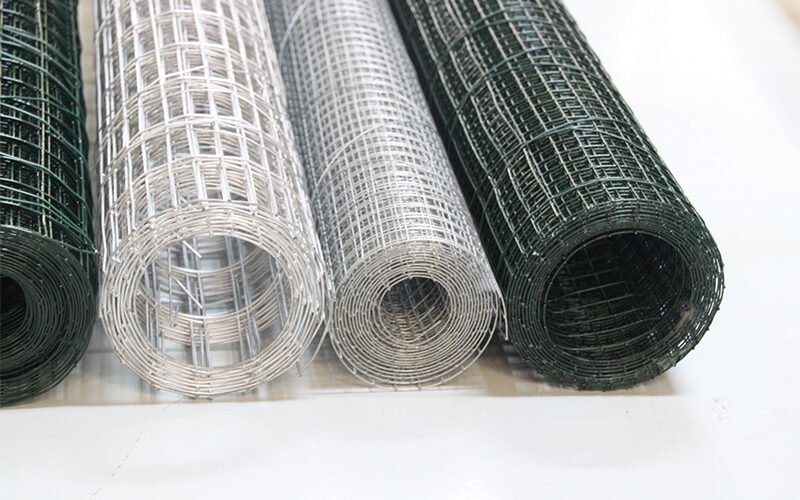

Wire thickness also plays a major role. Panels are often manufactured using 2.0 mm to 6.0 mm wire depending on application strength requirements. Hot-dip galvanized and PVC-coated finishes are chosen for outdoor environments to enhance corrosion resistance. The versatility of welded grid panels makes them suitable for slab reinforcement, perimeter fencing, machinery protection, and horticultural support systems.

Selecting the right standard size of welded wire mesh depends on your project load, exposure conditions, and installation method. Mesh panels can be custom-cut by suppliers to reduce on-site labor, making them easier to fit into complex layouts. High-precision welded panels also ensure consistent load distribution, preventing early cracking in concrete or deformation in fencing structures.

Below is a quick-reference table summarizing common mesh dimensions.

Product Specification Table (Welded Wire Mesh Trellis)

| Item | Details |

| Product Name | Welded Wire Mesh Trellis |

| Material Options | Low-carbon steel wire, galvanized steel wire, stainless steel (304/316) |

| Surface Treatment | Hot-dip galvanizing, electro-galvanizing, PVC coating (optional) |

| Wire Diameter | 1.0 mm – 3.0 mm (18–11 gauge) |

| Mesh Opening Size | 1/2” × 1/2”, 1” × 1”, 2” × 2”, or customized spacing |

| Welding Method | Precision resistance welding for strong, stable joints |

| Corrosion Resistance | High, depending on coating and environment |

| Roll Height | 24”, 36”, 48”, or custom size |

| Roll Length | Standard 25 ft, 50 ft, 100 ft |

| Panel Options | Flat welded mesh panels available for rigid trellis systems |

| Key Features | Strong welds, uniform openings, rust-resistant surface, long-lasting performance |

| Applications | Plant climbing support, garden structures, fencing, protection barriers |

| Installation Method | Attach to wooden posts, metal frames, garden stakes, or wall anchors |

FAQ

Q1: Can welded mesh be made in custom sizes?

A: Yes, most factories offer tailored panels to reduce installation time.

Q2: What thickness is best for concrete?

A: Generally 4.0 mm–6.0 mm wire provides adequate structural strength.

Q3: Are rolls or panels better?

A: Panels are stronger and more precise, while rolls suit light-duty fencing.

Q4: Which coating lasts the longest outdoors?

A: Hot-dip galvanized coating offers the highest corrosion resistance.

Post a Comment