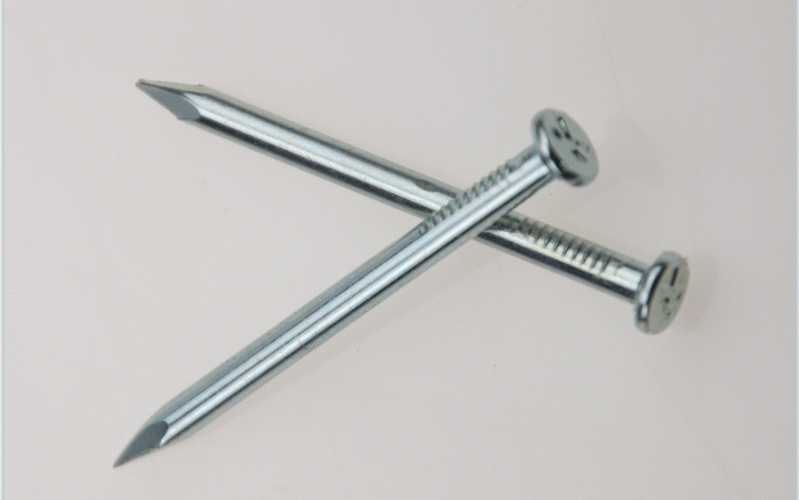

Building Material Common Wire Nail — What It Is and How It’s Used

A building material common wire nail is one of the most widely used fasteners in construction, woodworking, framing, and general carpentry. Simple in appearance but essential in performance, this nail type is valued for its strength, durability, and versatility across a wide range of building applications.

Common wire nails are typically made from low-carbon steel wire, a material that offers balanced hardness and flexibility. The production process begins with wire drawing, where steel rod is pulled through dies to achieve the desired diameter. Next, advanced nail-making machines cut the wire, form the flat head, and shape the diamond point.

After forming, the nails are polished and may undergo surface treatment. Many customers prefer galvanized coating—either electro-galvanized or hot-dip galvanized—to protect against moisture and corrosion, especially for outdoor or humid environments.

Some essential features of common wire nails include a thick shank for strong holding power, a broad head for improved hammer contact, and a sharp tip that penetrates wood easily without causing excessive splitting. These characteristics make them ideal for building frames, wooden pallets, packaging boxes, furniture structures, and temporary site constructions.

When sourcing these nails, buyers often consider size range, coating thickness, hardness, and packing requirements. Reputable factories offer customization for length, shank type, head shape, and zinc coating weight, ensuring compatibility with specific project needs. Consistent quality control—checking diameter, tensile strength, straightness, and rust resistance—is crucial for ensuring long-term reliability.

Choosing the right building material common wire nail guarantees stronger joints, faster installation, and improved overall workmanship in construction tasks.

✅ FAQ

Q1: What are building material common wire nails used for?

They are mainly used in construction framing, carpentry, furniture assembly, wooden packaging, and general fastening tasks.

Q2: Are galvanized common wire nails better than bright nails?

Yes. Galvanized nails resist moisture and rust, making them suitable for outdoor or high-humidity environments.

Q3: Can the nail size and packaging be customized?

Most manufacturers accept OEM orders for size, head type, shank style, coating thickness, and packaging.

Q4: What is the difference between common nails and finishing nails?

Common nails have a thicker shank and larger head, making them stronger for structural use. Finishing nails have smaller heads for decorative work.

Q5: What factors determine nail quality?

Steel grade, straightness, tensile strength, coating adhesion, and uniformity of head/point shape.

Post a Comment