2 inch common wire nails are one of the most widely used fasteners in construction, woodworking, and furniture manufacturing. They are produced from high-quality low-carbon steel wire such as Q195 / Q235 galvanized iron wire or black annealed wire, ensuring excellent hardness, holding power, and corrosion resistance.

Our factory provides complete nail-making solutions, including raw wire, nail making machines, polishing machines, and bulk packaging services.

✅ Manufacturing Process – “2 Inch Common Wire Nail Making”

Below is the standard production flow used in most professional nail factories in China:

1. Raw Material Selection

-

Q195 low carbon wire

-

Q235 galvanized iron wire

-

Wire diameter normally 2.0–2.3 mm for 2″ nails

2. Wire Drawing

Wire rod is drawn through molds to reach the exact diameter for nail making.

3. Nail Making (Nail Machine)

A nail making machine cuts the wire automatically:

-

Cuts to 2 inch (50 mm) length

-

Forms the nail head

-

Points the nail tip

Output: 350–450 pcs/min depending on machine model.

4. Nail Polishing

Nails are polished in a drum with sawdust and paraffin to create a shiny surface.

5. Surface Treatment (Optional)

-

Electro-galvanized

-

Hot dip galvanized

-

Black (no coating)

6. Packaging

-

1kg/box, 5kg/box, 25kg/carton

-

Or plastic bag + carton / woven bag

-

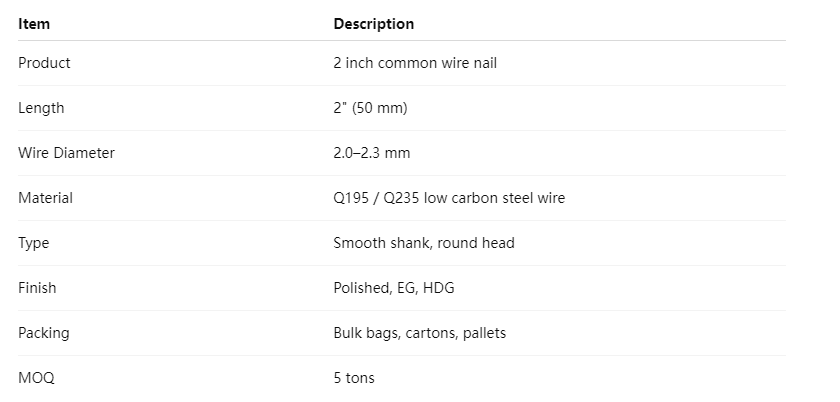

✅ Technical Specifications