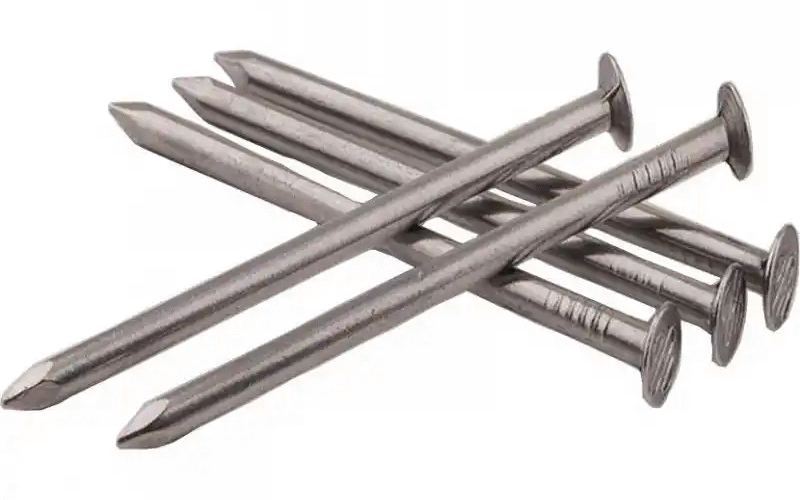

Common Nails Manufacturer — What Makes a Great Nail Supplier

A common nails manufacturer plays a vital role in the building, carpentry, and furniture industries by supplying essential fasteners that stand the test of time. A reputable manufacturer starts with high-quality low-carbon steel wire and follows a precise production process to guarantee consistency, strength, and corrosion resistance.

The manufacturing journey begins with selecting raw wire rods — typically Q195 or Q235 grade steel — chosen for their ductility and tensile strength. The wire is drawn to the correct diameter, cut, and formed into nails. Automated nail-making machines shape the head, sharpen the point, and polish the shaft.

After forming, the nails undergo surface treatment: commonly electro-galvanizing or hot-dip galvanizing to improve rust resistance. Some suppliers also offer bright-polished nails or special coatings, giving flexibility for different markets.

As nails come off the production line, strict quality control checks inspect length, head and point shape, coating quality, and bending strength. A reliable manufacturer will reject nails that fail to meet standards — ensuring customers get nails that drive straight, hold firm, and resist corrosion.

Whether used for wood framing, furniture assembly, or general construction, nails from a trustworthy common-nail factory deliver reliable performance. Moreover, many Chinese nail manufacturers export globally, offering large output capacity and custom orders for head type, length, and finish — ideal for wholesalers needing volume and consistency.

Choosing a reputable common nails manufacturer ensures you receive nails that meet your project’s needs — strong, durable, and cost-effective.

✅ FAQ(Frequently Asked Questions & Answers)

Q1: What materials are most common nails made from?

Common nails typically use low-carbon steel wire rods (e.g. Q195 / Q235), chosen for good ductility and consistent strength.

Q2: Why is galvanization important in nails?

Galvanized or zinc-coated nails resist rust and corrosion, especially in humid or outdoor environments, extending their usable life.

Q3: Can nail specifications be customized by the manufacturer?

Yes. Many manufacturers accept OEM orders — different lengths, head types, finishes, and packaging are customizable to meet specific buyer requirements.

Post a Comment