Wire rope cable is one of the most essential components in lifting, rigging, and heavy-duty load-bearing applications. As someone deeply involved in wire products and industrial materials, I rely on wire rope whenever strength, stability, and long-term durability are non-negotiable.

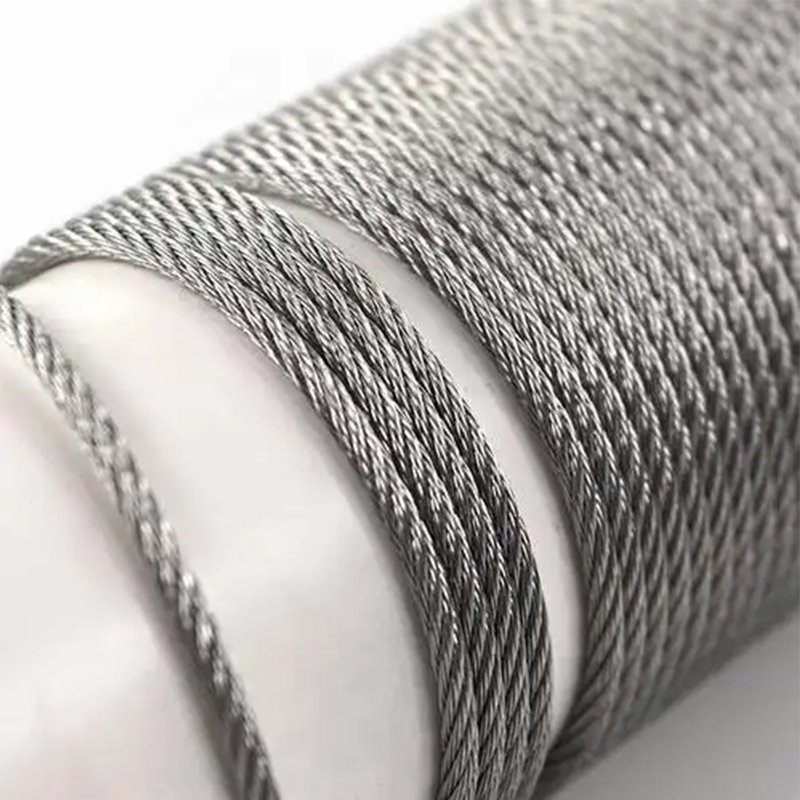

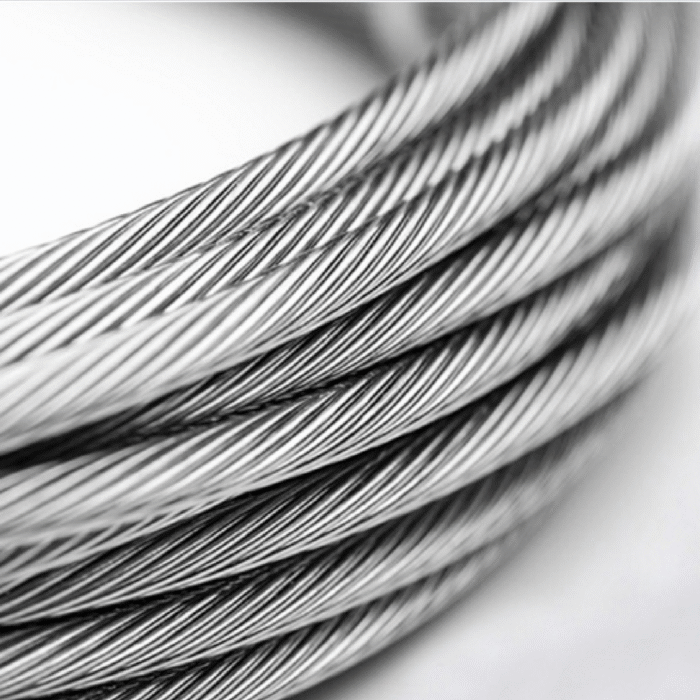

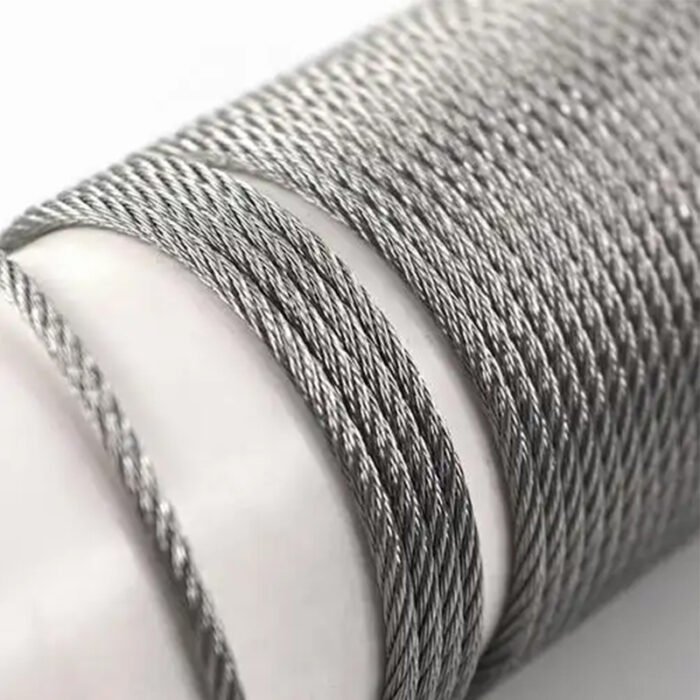

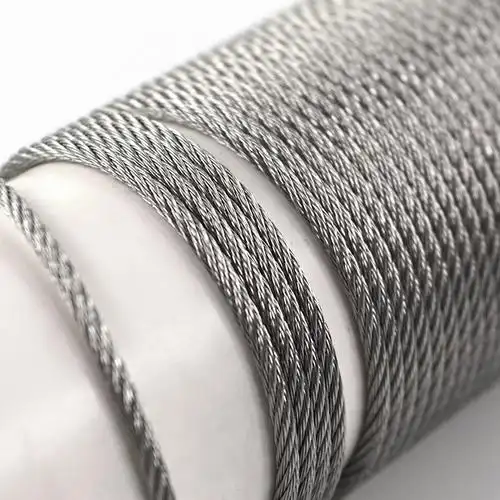

This product is engineered from multiple strands of high-tensile steel wire twisted together, creating a flexible yet incredibly strong structure capable of handling extreme loads and harsh working environments.

The performance of wire rope comes from its unique construction. Each individual wire strand contributes to flexibility, while the collective bundle delivers exceptional tensile strength.

This combination allows wire rope cable to withstand tension, shock loads, abrasion, pressure, and constant movement without compromising safety or structural integrity. In industrial use, this reliability is crucial.

Wire rope cable is used widely across construction, marine operations, mining, oil and gas, forestry, transportation, and manufacturing. You will find it in cranes, hoists, elevators, winches, towing systems, suspension setups, and structural support applications.

In marine environments, galvanized and stainless steel variants offer excellent corrosion resistance, ensuring dependable performance even when exposed to moisture, salt, or chemicals.

In construction and lifting work, the cable must support heavy loads with precision and stability, making high-quality materials and strict production standards essential.