4 ft Black Welded Wire Fence: The Best Choice for Strong, Stable Fencing (With Wire Mesh Comparisons)

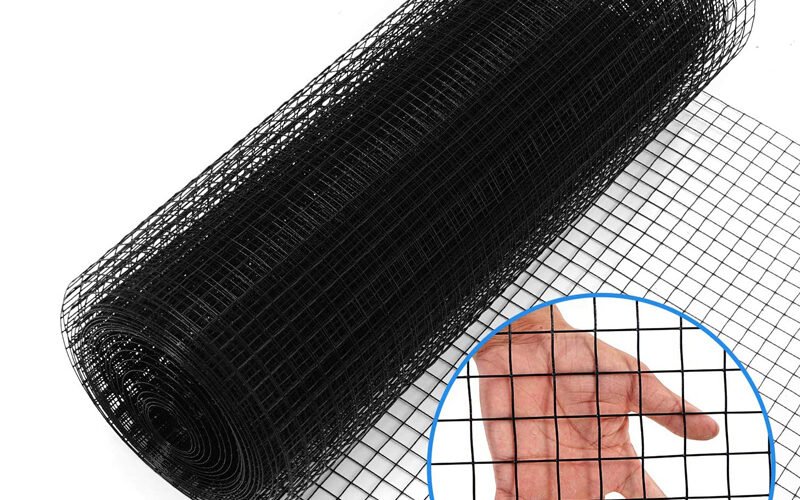

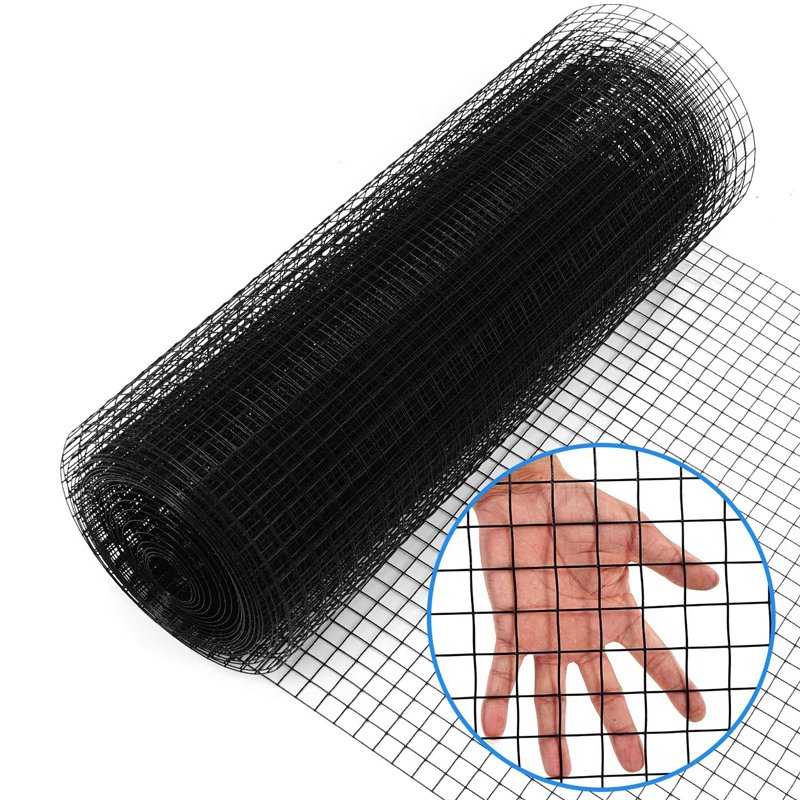

Among many fencing options, the 4 ft black welded wire fence stands out for its structural stability, clean appearance, and excellent weather resistance. It is a top choice for residential gardens, community spaces, animal enclosures, and landscape projects. As a typical wire mesh product, its core advantage comes from the combination of a welded structure + black coating + 4 ft height, which balances security, durability, and maintenance costs.

1. Why Choose a 4 ft Black Welded Wire Fence?

First, the 4 ft (about 1.2 meters) height is moderate—it clearly defines boundaries and prevents pets from escaping, without blocking sightlines like taller fences. The black coating gives the fence a modern, understated look that fits well with gardens, yards, neighborhoods, and parks. Compared to traditional wooden or wrought iron fences, welded wire fences are lighter, easier to install, and more impact-resistant, with lower maintenance needs.

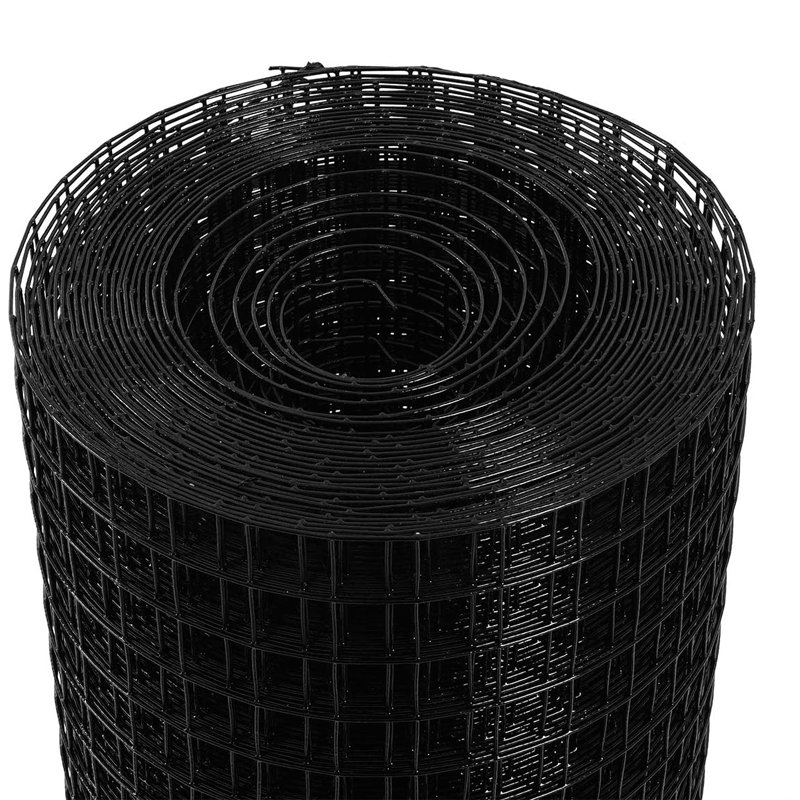

The key feature of welded wire fencing is that each intersection is welded and fixed, forming a rigid mesh panel. Compared with woven wire mesh, welded mesh does not loosen or deform over time, making it more suitable for long-term, load-bearing fencing applications. For landscape protection, pet enclosures, children’s play areas, and even industrial site partitioning, welded mesh offers more reliable structural support.

2. Comparison with Other Wire Mesh Types: Welded Mesh vs Woven Mesh vs Hexagonal Mesh

(1) Welded Mesh vs Woven Mesh

Woven mesh is commonly used for agricultural fences, lawn protection, and lightweight barriers. It is flexible and cost-effective but can deform or loosen under continuous stress. In contrast, welded mesh has fixed intersections and stronger rigidity, making it better for fences that must withstand push, pull, or impact.

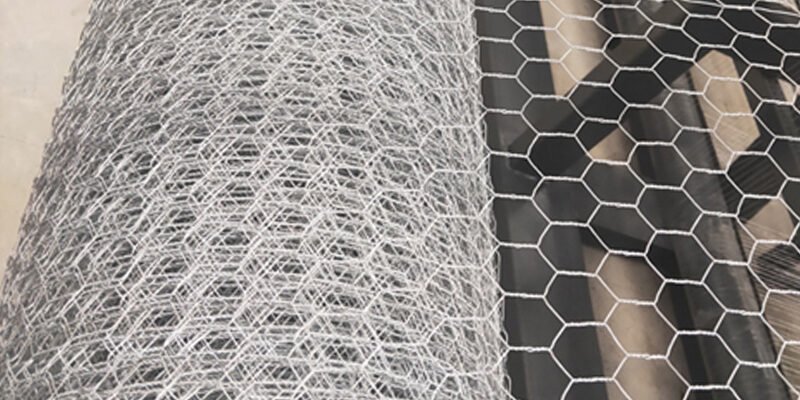

(2) Welded Mesh vs Hexagonal Mesh

Hexagonal mesh (chicken wire) is widely used in poultry cages, farm fences, and soil reinforcement. It is flexible and adapts well to uneven terrain. However, welded mesh is more suitable for flat, panel-based fencing, offering better flatness and easier installation. For projects that require a neat appearance and consistent structure, welded mesh is more advantageous.

(3) Welded Mesh vs Welded Wire Mesh Panels

The 4 ft black welded wire fence is actually a typical application of welded wire mesh panels. In a fencing system, it is usually combined with posts, clamps, and bases to form a complete fence solution. Compared with standalone mesh panels, a complete fence system is faster to install and provides higher overall strength and uniform appearance.

3. Suitable Application Scenarios: More Than Just a Fence, It’s a System Solution

The 4 ft black welded wire fence is widely used in:

-

Residential gardens and yard protection

-

Pet and animal enclosures

-

Parks and community public spaces

-

Schools and children’s play areas

-

Small farms and livestock partitions

-

Temporary construction site barriers

In real projects, welded wire fencing often works together with other wire mesh products. For example:

-

In livestock farms, welded mesh can be used for outer enclosures while hexagonal mesh is used for inner partitions or nesting protection.

-

On construction sites, welded mesh fences can be combined with welded wire mesh reinforcement for ground or wall reinforcement.

-

In landscaping, welded mesh fences can be paired with galvanized protective mesh for plant support or bird and animal prevention.

4. Key Materials and Quality Standards: The Core of Fence Lifespan

The core material of a 4 ft black welded wire fence is usually low-carbon steel or high-strength steel wire, with a PVC or powder coating surface treatment. The coating not only improves appearance but also provides corrosion protection to prevent rapid rusting in rainy, humid, or coastal environments.

When choosing a fencing material, buyers should focus on:

-

Wire diameter and mesh opening size (affects strength and appearance)

-

Coating thickness and adhesion (affects weather resistance and lifespan)

-

Welding quality (affects overall structural stability)

-

Panel flatness and dimensional accuracy (affects installation and aesthetics)

Compared with other common fencing materials, welded wire fences offer better durability and lower long-term maintenance costs. They don’t require frequent repainting or part replacement, making them more cost-effective over time.

5. Why Factory Direct Supply Is More Advantageous?

As a wire mesh product manufacturer, we can provide stable material control, mass production capacity, and customization services. For 4 ft black welded wire fence projects that require consistent specifications and quality, factory direct supply significantly reduces procurement risk and cost.

We also support customized solutions, such as:

-

Different heights (3 ft, 5 ft, 6 ft)

-

Various mesh sizes (50×50mm, 75×75mm, 100×100mm)

-

Different coating types (PVC, powder coating, hot-dip galvanized + coating)

-

Matching posts and clamp systems (for fast installation)

This “product + system + accessories” supply method helps contractors, distributors, and project buyers complete installation faster and maintain it more easily.

Get Wire Mesh Solutions for Caged Chicken Farms

Looking for durable welded wire mesh for poultry cage systems? We supply factory-direct wire mesh solutions with stable quality and custom specifications for bulk orders.

📲 WhatsApp: +86 18830227875

Contact us now to get technical details, samples, or a fast quotation.

Factory direct | Bulk supply | Export ready

Factory Advantages

As a professional manufacturer of steel wire panels and fencing products, our factory is built to support large-volume, stable, and customized B2B supply.

1. Manufacturer-Direct Pricing

We operate our own production lines, eliminating middlemen and offering competitive factory prices for wholesalers, distributors, and project buyers.

2. Automated Welding Production

Advanced automatic welding machines ensure:

-

Consistent panel dimensions

-

Strong and uniform weld points

-

Stable quality across bulk orders

This guarantees reliability for long-term cooperation.

3. Custom Specifications Available

We support OEM and customization, including:

-

Wire diameter and mesh opening

-

Panel size and structure

-

Surface treatment (galvanized, PVC coated)

-

Packaging and private labeling

Ideal for different regional standards and market demands.

4. Strict Quality Control

From raw material inspection to final packing, every step follows internal QC procedures to ensure durability, strength, and corrosion resistance.

5. Strong Bulk Supply Capacity

With sufficient raw material stock and scalable production, we can handle:

-

Large wholesale orders

-

Project-based quantities

-

Continuous monthly supply

6. Export-Oriented Packaging & Logistics

Panels are packed in bundles or pallets, suitable for container loading, helping buyers reduce freight cost and damage risk during transportation.

7. Experienced B2B Export Team

Our team understands international trade requirements and provides support for:

-

Technical specifications

-

Documentation

-

On-time delivery coordination

Post a Comment