Introduction: Why Mesh Opening Size Matters in Wire Applications

1 4 inch mesh wire is widely selected in fencing and enclosure projects where strength, airflow, and visibility must work together. The opening size offers a practical balance that supports containment without creating a closed or bulky barrier. From agricultural installations to industrial partitions, this mesh format has become a reliable option for professional buyers and contractors.

Understanding how this wire mesh performs in real-world environments helps buyers choose the right configuration, coating, and wire thickness for long-term value.

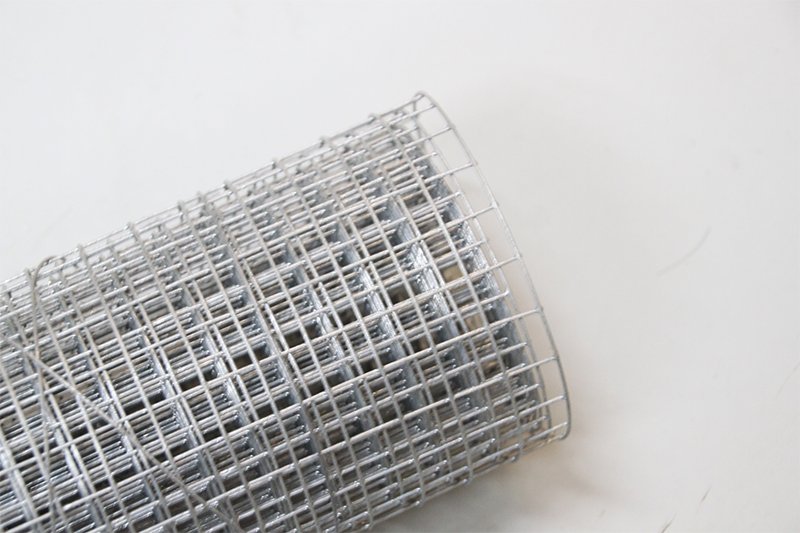

Understanding the Structure of Quarter-Inch Wire Mesh

The defining feature of this mesh type is its uniform square opening, created through precise welding or weaving processes. Each intersection is engineered to maintain alignment and spacing, ensuring consistent load distribution across the surface.

Compared with larger openings, this mesh offers improved containment. Compared with finer grids, it allows better airflow and reduced material weight. This structural balance is especially important in applications where both strength and visibility are required.

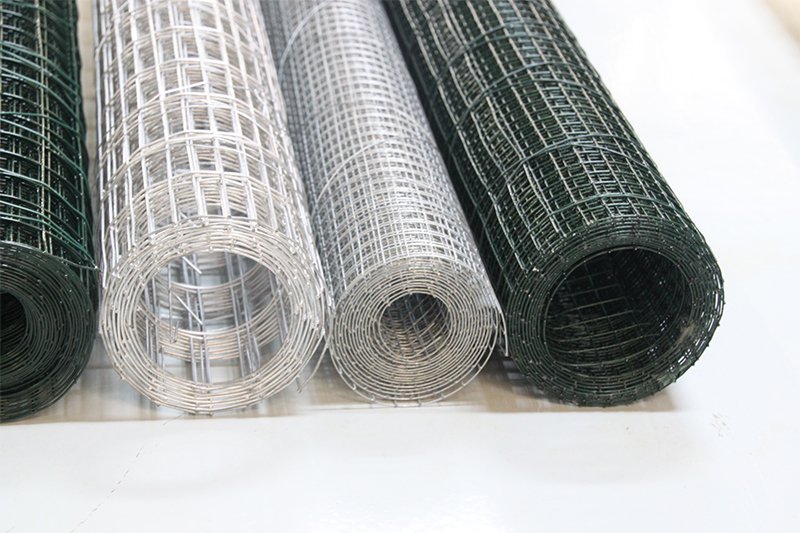

Materials Used and Their Performance Advantages

Most products of this type are manufactured from low carbon steel wire due to its flexibility and tensile strength. Depending on the working environment, different surface finishes can be applied to enhance durability.

Galvanized finishes provide strong resistance to rust and moisture, making them suitable for outdoor exposure. PVC-coated versions add an extra protective layer while improving appearance and touch safety. These treatments extend service life and reduce maintenance costs over time.

Manufacturing Process and Quality Control

The production process begins with wire drawing to achieve precise diameters. After straightening, the wire is welded or woven using automated machinery to ensure uniform spacing. Advanced welding techniques create strong joints that resist deformation under pressure.

After forming, the mesh undergoes surface treatment and inspection. Quality control checks focus on mesh accuracy, weld strength, coating adhesion, and roll or panel consistency. This ensures each batch meets export and industrial standards.

Common Applications Across Industries

This mesh configuration is frequently used in animal enclosures, poultry housing, garden fencing, and protective barriers. It is also applied in storage cages, warehouse partitions, and equipment guards where airflow and visibility are essential.

In agricultural settings, the mesh helps protect livestock while allowing natural ventilation. In industrial environments, it serves as a lightweight yet secure barrier that integrates easily with frames and posts.

Installation Flexibility and Handling Benefits

One advantage of this mesh style is its ease of handling. It can be cut, bent, or fixed using standard tools, reducing installation time. Available in rolls or rigid panels, it adapts to both temporary and permanent structures.

Installers often pair it with steel posts, wooden frames, or existing fence systems. This compatibility lowers overall project costs and simplifies future modifications or repairs.

Comparison with Other Wire Mesh Types

When compared to hexagonal netting, this mesh offers greater rigidity and shape retention. Against chain link fencing, it provides tighter spacing and improved containment for smaller animals or materials.

Welded constructions also outperform woven alternatives in environments requiring consistent panel shape and resistance to impact. These distinctions make it suitable for buyers seeking predictable performance rather than decorative use.

Choosing the Right Specification for Your Project

Selecting the correct wire diameter and coating depends on application conditions. Thicker wire improves strength, while protective coatings enhance corrosion resistance. Roll length and panel size should align with installation layout to minimize waste.

Professional suppliers often offer customization options to match project requirements, helping buyers optimize both performance and budget.

Long-Term Value for Wholesale and Project Buyers

For bulk purchasers, consistency and durability are critical. Reliable manufacturing and stable material sourcing ensure uniform quality across shipments. This reliability reduces replacement frequency and supports long-term planning for contractors and distributors.

In export markets, standardized packaging and compliance with international specifications further enhance logistical efficiency.

Conclusion: A Practical Wire Mesh Solution

By combining balanced opening size, dependable strength, and flexible installation options, this wire mesh category continues to meet the needs of agricultural, industrial, and commercial users. Its adaptability and performance make it a dependable choice for projects requiring both protection and openness, while maintaining cost efficiency over time.

We supply factory-direct wire mesh with stable quality, export-ready packaging, and custom specifications.

📲 WhatsApp: +86 18830227875

Contact us now for technical support, samples, and a fast quotation.

Manufacturer | Wholesale Supply | OEM Available

weld wire

Post a Comment